What is Switchgear?

Definition of Switchgear: The apparatus used for switching, controlling and protecting the electrical circuits and equipment is known as switchgear.

The term ‘switchgear’ is a generic term that includes a wide range of switching devices like circuit breakers, switches, switch fuse units, off-load isolators, HRC fuses, contactors, miniature circuit breakers, ELCBs, GFCIs etc.

It also includes the combination of these switching devices with associated control, measuring, protecting and regulating equipment. The switchgear devices and their assemblies are used in connection with the generation, transmission, distribution, and conversion of electrical energy.

We all are familiar with low voltage switches and low voltage fuses like rewirable fuses in our homes. Switches are used for opening and closing an electric circuit while fuses are used for over-current and short-circuit protection. In such a way, every electrical device wants a switching and a protecting device.

Various forms of switching and protective devices have been developed. Thus switchgear can be taken as a general term covering a wide range of equipment concerned with the switching, protection, and control of various electrical equipment.

The function of a Switchgear

Switchgear has to perform the functions of carrying, making and breaking the normal load current like a switch.

In addition, it has to perform the function of clearing the fault current for which sensing devices like current transformers, potential transformers and various types of relays, depending on the application, are employed.

There also has to be provision for metering, controlling and data, wherein innumerable devices are used for achieving the switching function.

Thus switchgear can include circuit breaker, current transformers, potential transformers, protective relays, measuring instruments, switches, fuses, MCBs, surge arrestors, isolators, and various associated types of equipment. (Related components can be found at electronic components distributor)

Now let’s look into the components of switchgear in detail.

Components of Switchgear

Switchgear essentially consists of switching and protecting devices such as switches, fuses, isolators, circuit breakers, protective relays, control panels, lightning arrestors, current transformers, potential transformers, auto reclosures, and various associated equipment.

(For more details, visit a complete list on components of switchgear.)

Some types of equipment are designed to operate under both normal and abnormal conditions. Some equipment is meant for switching and not sensing the fault.

During normal operation, switchgear permits to switch on or off generators, transmission lines, distributors and other electrical equipment. On the other hand, when a failure (e.g. short circuit) occurs on any part of the power system, a heavy current flows through the equipment, threatening damage to the equipment and interruption of service to the customers.

However, the switchgear detects the fault and disconnects the unhealthy section from the system. (For more details visit working of a circuit breaker and protective relays.)

Similarly, switching and current interrupting devices play a significant role in the modern electrical network, right from generating stations, transmission substations at different voltages, distribution substations, and load centers. The switching device here is called a circuit breaker.

The circuit breaker, along with associated devices for protection, metering, and control regulation, is called switchgear.

Read in detail about Components of Switchgear

Evolution of Switchgear

The switchgear equipment is essentially concerned with switching and interrupting currents either under normal or abnormal operating conditions.

The tumbler switch with ordinary fuse is the simplest form of switchgear and was used to control and protect lights and other equipment in homes, offices, etc.

For circuits of a higher rating, a high-rupturing capacity (H.R.C.) fuse in conjunction with a switch may serve the purpose of controlling and protecting the circuit. However, such switchgear cannot be used profitably on a high voltage system (33 kV) for two reasons.

- Firstly, when a fuse blows, it takes some time to replace it and consequently, there is an interruption of service to the customers.

- Secondly, the fuse cannot successfully interrupt large fault currents that result from the faults on the high voltage system.

With the advancement of the power system, lines and other equipment operate at high voltages and carry large currents. When a short circuit occurs on the system, a heavy current flowing through the equipment may cause considerable damage.

In order to interrupt such heavy fault currents, automatic circuit breakers (or simply circuit breakers) are used.

A circuit breaker is one switchgear which can open or close an electrical circuit under both normal and abnormal conditions.

Even in instances where a fuse is adequate, as regards to breaking capacity, a circuit breaker may be preferable. It is because a circuit breaker can close circuits, as well as break them without replacement and thus has a wider range of use altogether than a fuse.

[For more details, go through What is a fuse and How it Works? and Working of Circuit Breaker]

Essential Features of Switchgear

The essential features of switchgear are :

- Complete Reliability

- Absolutely certain discrimination

- Quick operation

- Provision for manual control

1. Complete reliability

With the continued trend of interconnection and the increasing capacity of generating stations, the need for reliable switchgear has become of paramount importance.

This is not surprising because it is added to the power system to improve reliability. When a fault occurs on any part of the power system, they must operate to isolate the faulty section from the remainder circuit.

2. Absolutely certain discrimination

When a fault occurs on any section of the power system, the switchgear must be able to discriminate between the faulty section and the healthy section.

It should isolate the faulty section from the system without affecting the healthy section. This will ensure continuity of supply.

3. Quick operation

When a fault occurs on any part of the power system, the switchgear must operate quickly so that no damage is done to generators, transformers and other equipment by the short-circuit currents.

If the fault is not cleared quickly, it is likely to spread into healthy parts, thus endangering complete shut down of the system

4. Provision for manual control

Switchgear must have provision for manual control. In case the electrical (or electronics) control fails, the necessary operation can be carried out through manual control.

Classification of Switchgear

Switchgear can be classified on the basis of the voltage level into the following

- Low voltage (LV) Switchgear

- Medium voltage (MV) Switchgear

- High voltage (HV) Switchgear

1. Low Voltage Switchgear

Switchgear for low voltage applications is generally rated up to 1000 V AC and 1500V DC.

The commonly used low voltage devices include oil circuit breakers(OCBs), air circuit breakers (ACBs), switch fuse units (SFUs), off-load isolators, low voltage fuses, HRC fuses, earth leakage circuit breakers (ELCBs), Residual Current Protective Devices (RCCB & RCBO), miniature circuit breakers (MCB) and moulded case circuit breakers (MCCB) etc i.e. all the accessories required to protect the LV system.

The most common use of this is in LV distribution board.

Read more about Low Voltage Switchgear.

2. Medium Voltage Switchgear

Switchgear for medium voltage applications is rated from 3.3 kV to 33 kV class.

Medium voltage switchgear is mainly used for the distribution of electrical energy connected to various electrical networks. They include most of the substation equipment such as minimum oil circuit breakers, bulk oil circuit breakers, air magnetic, SF6 gas-insulated, vacuum, and gas-insulated switchgear.

They may metal-enclosed indoor type, metal-enclosed outdoor type, outdoor type without a metal enclosure, etc. The interruption medium maybe oil, SF6, and vacuum.

The main requirement of MV power network is to interrupt the current during faulty condition irrespective of what type of CB is used in the system. Although it may be capable of functioning in other conditions also.

Medium voltage switchgear should be capable of,

- Normal ON/OFF switching operation.

- Short circuit current interruption.

- Switching of capacitive currents.

- Switching of inductive currents.

- Some special application.

3. High Voltage Switchgear

The power system deals with the voltage above 36kV is referred to as high voltage.

As the voltage level is high the arcing produced during switching operation is also very high. So, special care to be taken during designing of high voltage switchgear.

High voltage circuit breakers (such as SF6 Circuit breaker or Vacuum Circuit breaker) are the main component of HV switchgear. Hence high voltage circuit breaker should have special features for safe and reliable operation.

Faulty tripping and switching operation of high voltage circuit breakers are comparatively very rare. Most of the time these circuit breakers remain at ON condition and may be operated after a long period of time. So Circuit Breakers must be reliable enough to ensure safe operation, as when required.

Read more about different types of High Voltage Circuit Breakers.

Indoor and Outdoor Switchgear

The main components of switchgear are circuit breakers, switches, bus-bars, instruments and instrument transformers.

It is necessary to house the switchgear in power stations and substations in such a way so as to safeguard personnel during operation and maintenance and to ensure that the effects of fault on any section of the gear are confined to a limited region.

Depending upon the voltage to be handled, switchgear may be broadly classified into

- Outdoor type Switchgear

- Indoor type Switchgear

Outdoor Switchgear

For voltages beyond 66 kV, we install outdoor switchgear equipment.

It is because, for such voltages, the clearances between conductors and the space required for switches, circuit breakers, transformers, and others equipment become so great that it is not economical to install all such equipment indoor.

The figure shows a typical outdoor sub-station with switchgear equipment. The circuit breakers, isolators, transformers, bus-bars, and all other substation equipment occupy considerable space on account of large electrical clearance associated with high voltages.

Indoor Switchgear

For voltages below 66 kV, switchgear is generally installed indoor because of economic considerations.

It is generally of metal-clad type. In this type of construction, all live parts are completely enclosed in an earthed metal casing. The primary object of this practice is the definite localization and restriction of any fault to its place of origin.

Switchgear Equipment

Switchgear covers a wide range of equipment concerned with switching and interrupting currents under both normal and abnormal conditions. It includes switches, fuses, circuit breakers, relays, current transformer, and other equipment.

Read switchgear in the substation for more details.

A brief account of these devices is given below.

1. Switches

A switch is a device which is used to open or close an electrical circuit in a convenient way. It can be used under full-load or no-load conditions but it cannot interrupt the fault currents.

When the contacts of a switch are opened, an arc is produced in the air between the contacts. This is particularly true for circuits of high voltage and large current capacity.

The switches may be classified into

- air switches

- oil switches

The contacts of the former are opened in the air and that of the latter is opened in oil.

- Air-break switch – It is an air switch and is designed to open a circuit under load. In order to quench the arc that occurs on opening such a switch, special arcing horns are provided. Read different types of air break switch.

- Isolator or disconnecting switch – It is essentially a knife switch and is designed to open a circuit under no load.

- Oil switches – As the name implies, the contacts of such switches are opened under oil, usually transformer oil.

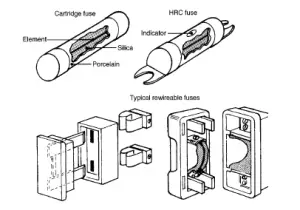

2. Fuses

A fuse is a short piece of wire or thin strip which melts when excessive current flows through it for sufficient time. It is inserted in series with the circuit to be protected.

When a short circuit or overload occurs, the current through the fuse element increases beyond its rated capacity. This raises the temperature and the fuse element melts (or blows out), disconnecting the circuit protected by it.

Read: What is a FUSE and How it Works?, Low Voltage Fuses, High voltage Fuses

3. Circuit Breakers

A circuit breaker is an equipment which can open or close a circuit under all conditions viz. no-load, full load and fault conditions. It is so designed that it can be operated manually (or by remote control) under normal conditions and automatically under fault conditions. For the latter operation, a relay circuit is used with a circuit breaker.

Low Voltage Circuit Breakers: Miniature Circuit Breaker, Moulded Case Circuit Breaker, Residual Current Circuit Breaker, Ground Fault Circuit Interrupter

High Voltage Circuit Breakers: Vacuum Circuit Breaker, SF6 Circuit Breaker, Oil Circuit Breaker, Air Blast Circuit Breaker

Read Circuit Breaker – Operating Principle and Arcing Phenomenon.

4. Protective Relays

Protective relays are vital parts of the switchgear equipment.

A relay is a device which detects the fault and supplies information to the breaker for circuit interruption.

The function of a protective relay is to initiate a signal to circuit breakers for disconnecting the elements of the power system when it develops a fault.

When a fault occurs the relay contacts are closed and the trip coil of the circuit breaker is energized to open the contacts of the circuit breaker.

There have been rapid developments in relaying technology during the last two decades. The most important advancement has been due to the advent of computer technology which has helped in the development of numerical relays.

Read in detail How Protective Relays Work?

5. Instrument Transformers

Instrument transformers (current transformer and voltage transformer) are used in switchgear installations for the measurement of electrical parameters for protection and metering purposes.

An instrument transformer in which the secondary current is substantially proportional to the primary current and differs in phase from it by approximately zero degrees is called a current transformer (CT).

A voltage transformer (VT) is an instrument transformer in which the secondary voltage is substantially proportional to the primary voltage and differs in phase from it by approximately zero degrees.

Capacitor Voltage Transformer (CVT) or Capacitor Coupled Voltage Transformer (CCVT) is a switchgear device used to convert high transmission class voltage into easily measurable values, which are used for metering, protection, and control of high voltage systems.

6. Surge Arresters

Surge Suppressors or Surge Arrestors are very important components of switchgear and substation installations.

These are used to protect the substation equipment from temporary over-voltages, switching impulses, and lightning impulses, and to a certain extent, very fast transient over-voltages.

Historically, spark gaps with air insulation were used as surge suppressors. Lightning arrestors, surge capacitors, surge suppressing reactors, and thyrite resistors with series gaps were used in the past for this purpose.

Innovation in this field has resulted in the advent of two commonly used types, viz. the metal oxide-based (ZnO) type and C-R type of surge arrestors/ suppressors.

7. Auto Reclosures and sectionalisers

Auto reclosures and sectionalisers are used in the distribution networks of medium voltage switchgear up to 33 kV class.

These equipment are useful for the fast automatic restoration of supply following transient faults in the system. The faults may be due to frequent lightning surges and in areas where power lines run through forests and trees.

These types of equipment are extensively used in the continents of America and Australia due to their distinct advantages over conventional switchgear.

8. Disconnect Switch / Isolator

Disconnect switches (Isolators) are devices which are generally operated off-load to provide isolation of main plant items for maintenance, on to isolate faulted equipment from other live equipment.

Air Insulated or open terminal disconnectors are available in several forms for different applications.

At the lower voltages, single break types are usual with either ‘rocker’ type or single end rotating post types being predominant.

At higher voltages, rotating center post, double end rotating post, vertical break, and pantograph type disconnectors are more common. Air break switches are used in lower voltage to disconnect on load.

Comments are closed.