An electrical fuse is the simplest current interrupting device for protection against excessive current. Fuses are divided into two primary categories: Low voltage fuses and High voltage fuses.

What is a Low Voltage Fuse?

A low voltage fuse is a protective switchgear device used in electrical circuits to interrupt or disconnect the flow of electrical current when it exceeds a safe level. These electrical fuses are designed specifically for use in low voltage systems, typically those operating at voltages below 1,000 volts.

Low voltage fuses are essential components in electrical systems to prevent damage to equipment, mitigate the risk of electrical fires, and ensure the safety of both people and property.

Also Read: Low voltage switchgear

Types of Low Voltage Fuses

There are various types of low voltage fuses, including semi-enclosed rewireable fuses and high-rupturing capacity (HRC) cartridge fuses, each with its own characteristics and applications.

These fuses are crucial for safeguarding electrical circuits by breaking the circuit when an overload or fault occurs, thus preventing further damage and ensuring the continued operation of the electrical system.

Thus Low Voltage Fuses can be further subdivided into two classes

- Semi-enclosed Rewireable Fuses

- Cartridge type fuses.

1. Semi-Enclosed Rewireable Fuses

A rewireable fuse, also known as kit-kat type, consists of (a) a base, and (b) a fuse carrier. The base is of porcelain and carries fixed contacts for connecting the incoming and outgoing phase wires. The fuse carrier is also of porcelain and holds the fuse element (tinned copper wire) between its terminals. The fuse carrier can be inserted in or taken out of the base as and when desired.

When a fault occurs, the fuse element melts and the circuit is interrupted. The fuse carrier is taken out and the blown-out fuse element is replaced by the new one. This type of fuse is used where low values of fault current are to be interrupted.

Features

A semi-enclosed rewireable fuse has the following features.

- The detachable fuse carrier permits the replacement of fuse element without any danger of coming in contact with live wires (parts).

- The cost or replacement is negligible.

Disadvantages

- The fuse element is subjected to deterioration due to oxidation through the continuous heating up of the element.

- Therefore, after some time, the current rating of the fuse is decreased i.e., the fuse operates at a lower current that originally rated. There is a possibility of renewal by the fuse wire of wrong size or by improper material.

- The protective capacity of such a fuse is uncertain as it is affected by the ambient conditions.

- Accurate calibration of the fuse wire is not possible because fusing current depends upon the length of the fuse element. For example, a longer fuse operates eariler than one of short length.

- This type of fuse has a low-breaking capacity and hence cannot be used in circuits of high fault level.

- There is a possibility of change of fuse wire both in diameter as well as improper material.

It is to be noted that semi-enclosed rewireable fuses are image up to 500 A rated current. Since their breaking capacity is low (e.g. on 400 V system the breaking capacity is about 4000 A), the use of this type of fuse is limited to domestic and lighting loads.

2. High-rupturing Capacity (HRC) Cartridge Fuse

When large concentrations of power are concerned, as in modern distribution system, it is essential that fuses should have a definite known breaking capacity and also that this breaking capacity should have high value. This requirement is met by the use of HRC cartridge fuse.

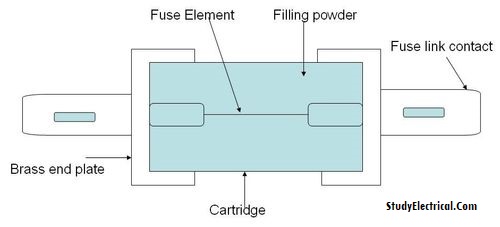

In its simplest form a HRC cartridge fuse consists of a heat resisting ceramic body having metal end caps to which are welded fusible silver (or bimetallic) current-carrying elements.

The space within the body surrounding the element is completely packed with a filling power which may be a chalk, plaster of paris, quartz or marble dust. This filling material acts as an arc quenching and cooling medium.

Under normal load conditions, the fuse element carries the normal current without overloading and is at a temperature below its melting point. When a fault occurs, the current increases and the fuse element melts before the fault current reaches’ its first peak. The heat produced in the process vaporizes the melted silver element and the chemical reaction between the silver vapor and the filling powder results in the formation of a high resistive substance which help in quenching the arc.

Features

The HRC cartridge type fuse has the following features:

- They have high speed of operation.

- They do not require maintenance.

- They do not deteriorate with age.

- They are cheaper as compared to other circuit interrupting devices of equal breaking capacity.

- They are capable of clearing high as well as low fault currents very efficiently.

- They are capable of providing reliable discrimination.

- They permit consistent performance.

Disadvantages

- They require replacement after each operation.

- The heat developed by the arc may affect the associated switches.

Additional Remarks

- HRC fuse with tripping device is also in use. The tripping device under fault condition causes the circuit breaker to operate.

- Low voltage HRC fuses may be designed to have a breaking capacity of 16,000 A to 30,000 A at 440 V.

- They are extensively used on low-voltage distribution system against overload and short-circuit conditions.

Comments are closed.