In an SF6 Circuit breaker, sulphur hexafluoride gas is used as the arc quenching medium.

The sulphur hexafluoride gas (SF6) is an electronegative gas and has a strong tendency to absorb free electrons. The contacts of the breaker are opened in a high-pressure flow sulphur hexafluoride (SF6) gas and an arc is struck between them.

The gas captures the conducting free electrons in the arc to form relatively immobile negative ions. This loss of conducting electrons in the arc quickly builds up enough insulation strength to extinguish the arc.

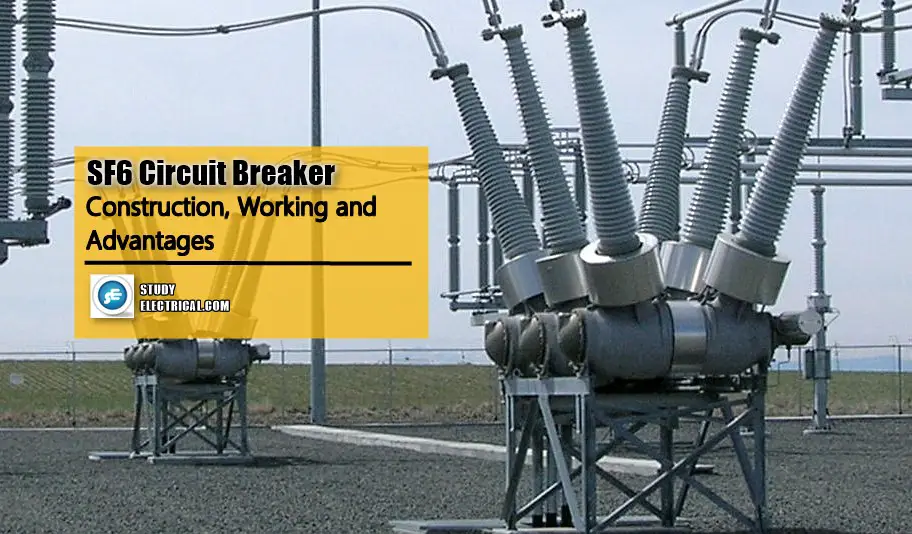

Comparing to other circuit breaker types, the SF6 circuit breakers have been found to be very effective for high power and high voltage service.

SF6 CBs are used in substations for all voltages ranging from 144 to 765 kV or even above. Continuous currents up to 8000 A, and symmetrical interrupting ratings up to 63 kA at 765 kV and 80 kA at 230 kV.

Construction of SF6 Circuit Breaker

The SF6 circuit breaker consists of two main parts:

- The Interrupter Unit

- The Gas System

Interrupter Unit

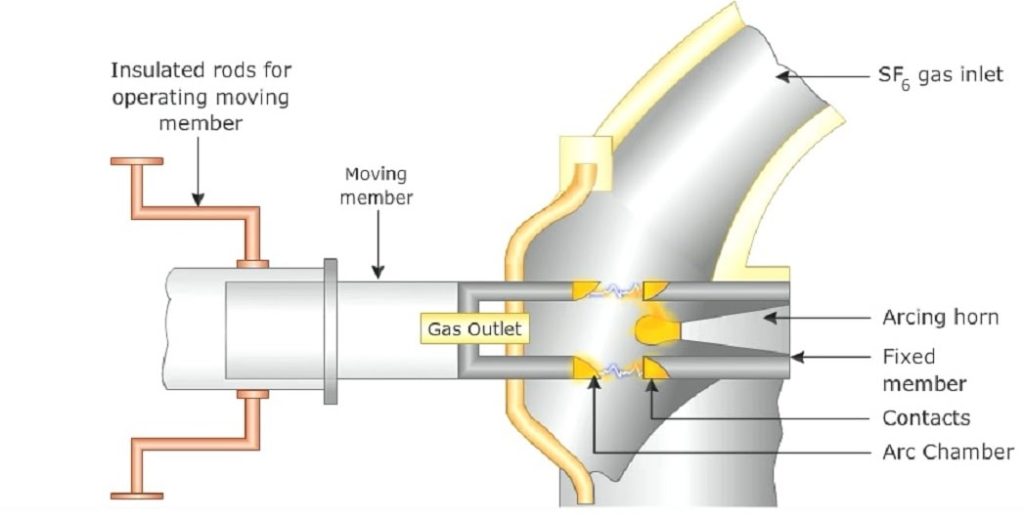

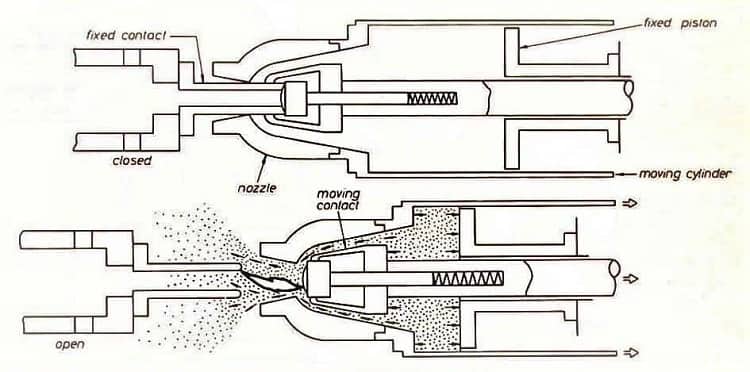

The interrupter unit of sulphur hexafluoride (SF6) circuit breaker consists of fixed and moving contacts enclosed in a chamber.

The chamber is called the arc interruption chamber which contains the SF6 gas. This chamber is connected to sulphur hexafluoride (SF6) gas reservoir. A valve mechanism is there to permit the gas to the arc interruption chamber.

When the contacts of the breaker are opened, the valve mechanism permits a high-pressure sulphur hexafluoride (SF6) gas from the reservoir to flow towards the arc interruption chamber.

The fixed contact is a hollow cylindrical current-carrying contact fitted with an arcing horn. The moving contact is also a hollow cylinder with rectangular holes in the sides.

The holes permit the sulphur hexafluoride gas (SF6) gas to let out through them after flowing along and across the arc.

The tips of fixed contact, moving contact, and arcing horn are coated with a copper-tungsten arc-resistant material.

Since SF6 gas is costly, it is reconditioned and reclaimed using the suitable auxiliary system after each operation of the breaker.

Gas System

Since the gas pressure is very high, a lot of care is to be taken to prevent gas leakage at joints by providing perfect scaling.

The low and high-pressure systems are fitted with low-pressure alarms and set of lockout switches which give a warning the moment the gas pressure drops below a certain value because otherwise there will be a reduction in the dielectric strength and arc quenching ability of the breaker is endangered.

If the danger limit is reached the safety devices immobilize the breaker. The overriding safety devices see to it that a fault in the control circuit does not permit the compressor to build up excessive pressure in the high-pressure reservoir or continue to pump gas into the atmosphere in the event of a major leak.

The gas is stored in the high-pressure chamber at 16 atmospheres whereas the gas pressure on the low-pressure side is 3 atmospheres.

The temperature is 20◦C in order to prevent liquefaction of gas in the high-pressure chamber at low temperature; a heater is fitted in the high-pressure chamber. A thermostat is set to the switch on when the ambient temperature falls below 16◦C.

Working of SF6 Circuit Breaker

The working of an SF6 circuit breaker is similar to the working of a normal circuit breaker we discussed in previous articles.

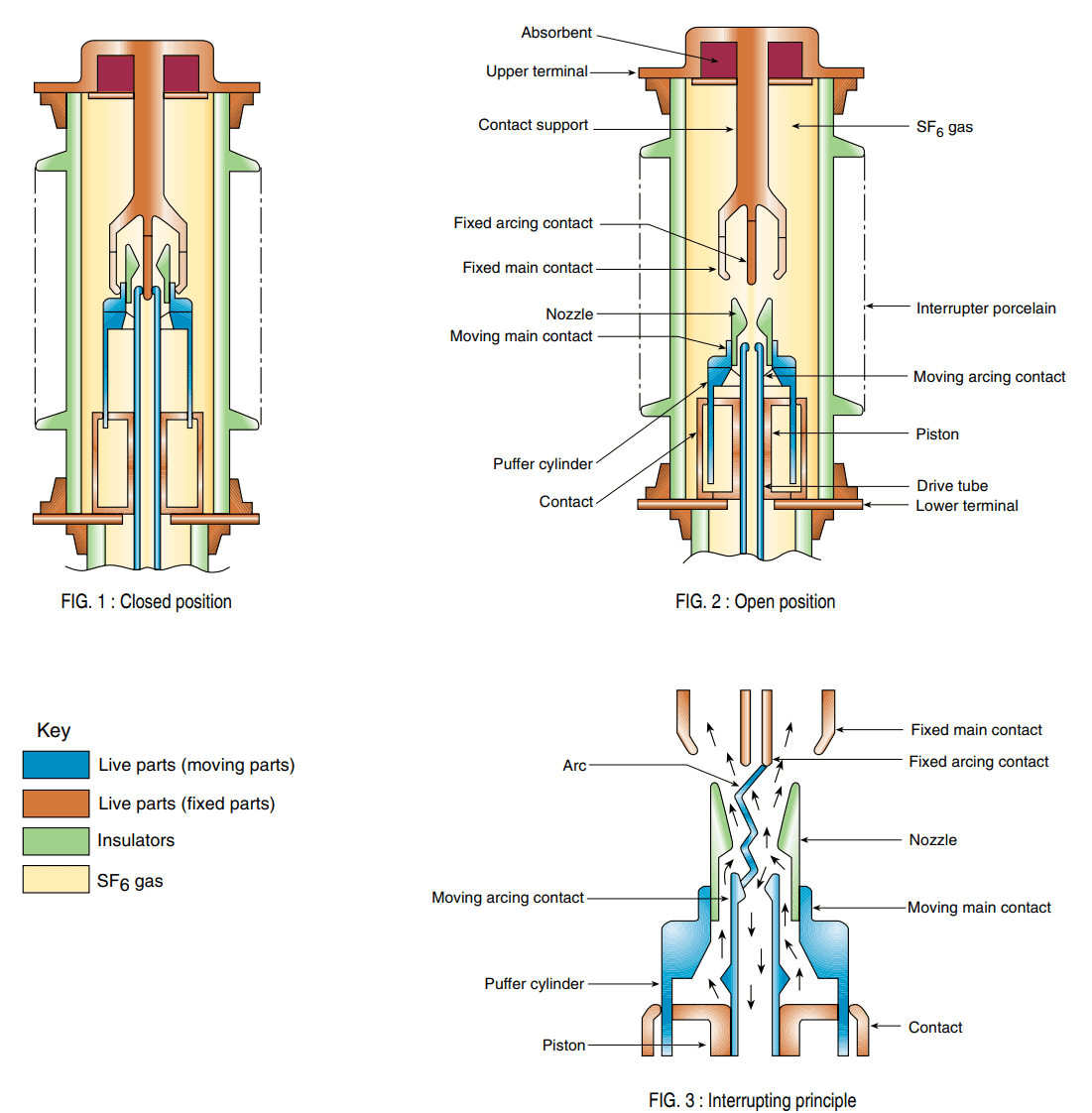

In the closed position of the breaker, the contacts remain surrounded by sulphur hexafluoride gas (SF6) gas at a pressure of about 2.8 kg/cm2.

When the breaker operates, the moving contact is pulled apart and an arc is struck between the contacts. (For more details visit arcing phenomenon in a circuit breaker.)

The movement of the moving contact is synchronized with the opening of a valve. The valve permits sulphur hexafluoride gas (SF6) gas at 14 kg/cm2 pressure from the reservoir to the arc interruption chamber.

The high-pressure flow of sulphur hexafluoride gas (SF6) rapidly absorbs the free electrons in the arc path. It forms immobile negative ions which are ineffective as charge carriers.

The result is that the medium between the contacts quickly builds up high dielectric strength and causes the extinction of the arc.

After the breaker operation (i.e. after arc extinction in circuit breaker), the valve is closed by the action of a set of springs.

SF6 CB Practical Working Animation

The practical opening and closing of an SF6 circuit breaker are animated in this video.

Types of SF6 Circuit Breaker

The SF6 circuit breaker has been developed by several manufacturers and several designs have emerged. The types of SF6 circuit breakers can be broadly identified as

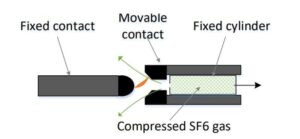

- Double pressure Type SF6 CB

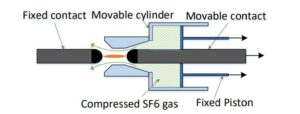

- Single Pressure Puffer Type SF6 CB

In double pressure type SF6 circuit breaker, the gas from the high-pressure system is released into the low-pressure system through a nozzle, during the arc extinction processes. This design has become obsolete.

The double pressure type system worked on a very similar basis to the air blast design, modified to make a closed-loop system for the exhaust gases. After the arc was quenched, gases in a low-pressure reservoir were filtered, compressed and then stored in the high-pressure reservoir for further use. Heaters were also fitted to ensure the gas did not become a liquid in low temperatures, which would make the medium unusable as an interrupter.

In single pressure type SF6 circuit breaker, the SF6 gas is compressed by the moving cylinder system and is released through a nozzle while extinguishing the arc. This design is most popular over a wide range of voltages from 13.6 kV to 760 kV.

SF6 breaker designs were first successfully manufactured by Westinghouse in 1957. By the1970’s, SF6 HV switchgear became popular.

Initial designs used a double pressure system, which was superseded in the 1970s by single-pressure puffer type design.

SF6 Circuit Breaker Designs (Live Tank & Dead Tank)

In both the double pressure and single pressure types, SF6 switchgear is of either the dead tank design or live tank design.

The dead tank design is for outdoor installations and live tank (or modular design) is for indoor installations. Increasingly dead tank breakers are integrated into SF6 insulated substations for indoor or outdoor installations.

The SF6 Circuit Breakers are available as in the following designs.

- live tank circuit breaker

- dead tank circuit breaker

- grounded tank designs.

The live tank means the interruption happens in an enclosure that is at line potential. Such SF6 CB has an interrupter chamber that is mounted on insulators and is at line potential. An interrupter with such a modular design can be connected in series to operate at higher voltage levels.

The dead tank means that interruption takes place in a grounded enclosure. Current Transformers are located on both sides of the break (i.e., interrupter contacts). In such circuit breakers, the interruption maintenance takes place at ground level. And it’s seismic withstand is better than circuit breakers with the live tank designs.

However, they require more insulating gas in order to provide the proper amount of insulation between the interrupter and the grounded tank enclosure. The modular dead tank CB has been specially developed for integration of SF6 insulated substation systems.

The grounded tank means that interruption happens in an enclosure that is partially at line potential and partially at ground potential. The evolution of the grounded tank CB design is the result of installing a live tank CB interrupter into a dead tank CB design.

Properties of SF6 Gas

The important properties of SF6 circuit breaker are:

- Toxicity

- SF6 is odorless, colorless, tasteless, and nontoxic in its pure state. It can, however, exclude oxygen and cause suffocation. If the normal oxygen content of air is reduced from 21 percent to less than 13 percent, suffocation can occur without warning.

- Dielectric strength

- SF6 has a dielectric strength about three times that of air at one-atmosphere pressure for a given electrode spacing. The dielectric strength increases with increasing pressure; and at three atmospheres, the dielectric strength is roughly equivalent to transformer oil.

- Thermal conductivity

- The thermal conductivity of SF6 is below that of air but its overall heat transfer capability, in particular when convection is taken into account is excellent being similar to that of gases such as hydrogen and helium and higher than that of air.

- At high temperatures, the thermal conductivity curve of SF6 reveals one of the exceptional qualities of the gas, which allows it to be used for extinguishing arcs by thermal transport.

- Arc quenching

- SF6 is approximately 100 times more effective than air in quenching spurious arcing. SF6 also has a high thermal heat capacity that can absorb the energy of the arc without much of temperature rise.

- Electrical properties

- The excellent dielectric properties of SF6 are due to the electronegative character of its molecules. It has a pronounced tendency to capture free electrons forming heavy ions with low mobility making the development of electron avalanches very difficult.

- Because of the arc quenching ability of SF6, corona and arcing in SF6 does not occur until way past the voltage level of onset of corona and arcing in air. SF6 will slowly decompose when exposed to continuous corona.

- Chemical properties

- SF6 fully satisfied the valence requirements of the sulfur molecule. Its molecular structure is octahedral with a fluorine molecule at each apex. The six bonds are covalent which accounts for the exceptional stability of this compound.

- SF6 can be heated without decomposition to 500°C in the absence of catalytic metals. SF6 is non-flammable and hydrogen, chlorine, and oxygen have no action on it. SF6 is insoluble in water and is not attacked by acids.

- Toxicity of arc products

- Toxic decomposition products are formed when SF6 gas is subjected to an electric arc. The decomposition products are metal fluorides and form a white or tan powder.

- Toxic gases are also formed which have the characteristic odor of rotten eggs.

Advantages and Disadvantages of SF6 Gas

In its pure state SF6 gas is colorless, odorless, tasteless and non-toxic. At room temperature and pressure, it is gaseous and has a density of 6.16 g/l, about five times the density of air. Since its critical temperature is 45.6°C it can be liquefied by compression and is normally transported as a liquid.

Due, to the superior arc quenching properties of sulphur hexafluoride gas (SF6) gas, the sulphur hexafluoride gas (SF6) circuit breakers have many advantages over oil circuit breaker and air blast circuit breakers.

Advantages of SF6 Circuit Breaker

The important advantages of SF6 Circuit Breaker are :

- The superior arc quenching property of sulphur hexafluoride gas (SF6). Due to this SF6 circuit breakers have very short arcing time. Hence SF6 gas is used in Gas Insulated Substations.

- Dielectric strength of sulphur hexafluoride (SF6) gas is 2 to 3 times compared to air. Thus SF6 breakers can interrupt much larger currents.

- The sulphur hexafluoride gas (SF6) circuit breaker gives noiseless operation due it’s closed gas circuit and no exhaust to atmosphere, unlike the air blast circuit breaker.

- The compact design of SF6 gas CBs substantially reduces space requirements and building installation costs.

- The SF6 gas circuit breakers can handle all known switching phenomena.

- SF6 gas circuit breakers perfectly can adapt to environmental requirements. They have completely enclosed gas system that eliminates any exhaust during switching operations.

- Contact separation is minimum in SF6 gas circuit breakers due to dielectric strength provided by the high-pressure SF6.

Disadvantages of SF6 Circuit Breaker

In general, the important disadvantage of the SF6 Circuit Breakers compared to other circuit breakers is their relatively high costs. The cost has been somewhat coming down in recent years.

Some other disadvantages of the SF6 Circuit breaker are:

- Heavy-duty switching operations can generate harmful by-products from decomposition. During typical sealed operation, these by-products will recombine into SF6. However, during arcs or in the event of switchgear failure, SF6 and its by-products can be released into the environment.

- Imperfect joints in the Sf6 Circuit breaker lead to leakage of the SF6 gas. Thus continuous monitoring devices are required.

- Arced SF6 gas is poisonous and should not be inhaled.

- While SF6 in its pure form is non-toxic, it does not support life and can, therefore, become a breathing hazard if it has collected. As it is heavier than air, it can typically collect close to the ground, in cable trenches or drainage systems, for example. Therefore, site personnel is instructed to take care of such environments.

- Exposure to solid by-products, if inhaled, include irritation to exposed skin and eyes, the nose, throat, and lungs; further symptoms can occur if sufficient volume reaches the gastrointestinal tract.

- Special facilities are required for transportation of gas, transfer of gas and for maintaining the quality of the gas. The deterioration of quality of gas affects the performance and hence reliability of the SF6 circuit breaker.

Safety and Maintenance of SF6 Circuit Breaker

The maintenance of the sf6 circuit breaker is necessary because of their importance for routine switching and for the protection of other equipment.

Electric transmission system breaks up and equipment destruction can occur if a circuit breaker fails to operate due to lack of preventive maintenance.

Breakers that remain idle for 6 months or more should be made to open and close several times in succession to verify proper operation and remove any accumulation of dust or foreign material on moving parts and contacts.

Although pure SF6 is not toxic, it contains no oxygen and will therefore not support life.

The high density of SF6, five times that of air means that any leak will tend to cause the gas to accumulate in low areas such as cable trenches, and operators should be made aware of the danger of suffocation.

However, a mixture of 20% oxygen, 80% SF6 can be breathed in safety, and such mixtures have been used in laboratory experiments on humans during a study of lung aerodynamics.

An arc in SF6 will produce lower fluorides of sulphur which are gaseous and toxic. These gases are effectively controlled and absorbed by suitable agents, e.g. activated alumina or molecular sieves, included within the equipment.

In addition, the gases have a pungent unpleasant odour, which gives adequate warning of their presence.

As mentioned above, metallic fluorides in the form of fine dust are also produced in the interrupting process. These fluorides are irritants, and so most manufacturers recommend wearing a dust mask, goggles and plastics gloves during interrupter maintenance, although there are recorded notable exceptions.

The very long life of SF6 circuit breaker contacts means that, in the majority of cases, the contacts and nozzles will never have to be changed, minimizing the problem of maintenance, although periodic routine checks on the acidity of the gas will be necessary to ensure that the absorbing agent is still active and efficient.

Next: Vacuum Circuit Breakers

Comments are closed.