The goal of the auto reclosing in power lines is to restore the line to service as quickly as possible after a temporary fault in the transmission line.

Automatic reclosing can be done as a three pole auto reclosing or a single pole auto reclosing. During a three pole auto reclosing the line will be de-energized completely for all three phases even for a single phase to ground fault. A single pole auto reclosing only de-energizes the faulted phase of a single phase to ground fault.

Automatic recloser is a key element in the concept of self-healing grids. According to statistics, around 85-95% of faults in transmission and distribution networks are temporary faults. These faults disappear a certain time after de-energization of the faulted sections of the network. Automatic recloser is used to recover the original status of the network without any human interaction.

Auto-reclosing, therefore, provides significant advantages.

- Outage times will be short compared with systems where station personnel have to turn our and re-energize the lines after a fault. Such emergency visits often entail long trips at inconvenient hours and in bad weather, which will have as consequence a long outage time.

- Personnel can be saved if several substations can be unmanned. It is also possible to reduce the number of emergency visits to unmanned substations provided merely with alarm transmitters if they are equipped with an auto-reclosing system.

In other words, auto reclosing reduces operating costs and improves the reliability of service of the network.

In the case of transmission lines between network sections with their own generating facilities auto-reclosing is generally justified with respect to the network stability.

The choice of one or more reclosing shots, high-speed or delayed (low-speed) auto-reclosing, single-phase or three-phase auto reclosing depends on various factors.

Before going to the details of auto reclosing it is better to understand the different types of faults in the transmission system.

Different Types of Faults

Depending upon the time, for which the faults exist on the system, are classified as follows:

- Transient fault

- Semi-permanent fault and

- Permanent Fault.

1. Transient Fault

The transient fault exists only for a short time. They can be removed faster still if the line is disconnected from the system momentarily so that the arc extinguishes.

After the arc is deionized, the line can be reclosed to restore normal service.

A characteristic feature of transient faults is that they either disappear after a short dead time or that they disappear quickly without any action being taken.

Lightning is the most usual cause of this type of fault. The overvoltages induced in the lines generally cause flashovers across the insulator strings. They are seldom extinguished on its own.

This means that the line must be tripped for de-ionization of the fault path and can then be re-energized, without the fault recurring.

Other transient faults may be caused by swinging conductors contacting each other due to high winds or the shedding of ice. Unfortunately, conductor swinging due to ice shedding has the characteristic that the conductors of different phases may contact each other several times in succession and the fault can then be interpreted as a permanent fault.

Birds, temporary contact with foreign objects such as trees, etc., can also cause transient faults.

It is found that about 80% of the faults are transient faults, 12% semi-permanent and 8% are permanent faults.

2. Semi-permanent Fault

If it is a semi-permanent fault, maybe due to a twig falling on the power conductor or a bird spanning the power conductors.

Reclosing could have resorted with some delay so that the cause of the fault could be burnt away during a time delay trip and the line could be reclosed to restore normal service.

A fault of this type may be caused by, for example, a tree branch falling on the line. It is burnt up by the are when the line is re-energized.

A further 10 percent or so of all reclosers are consequently successful with the second shot. If a third shot is made, only a further 1 to 2 percent of the reclosers are successful. More than two shots are therefore generally rather meaningless and only subject the breaker to unnecessary wear.

3. Permanent Fault

However, for permanent fault reclosing does not help as it has to be attended and removed, and the line is to be taken out till the fault is cleared.

Permanent faults, such as a broken conductor, the collapse of a line tower, a tree leaning against the line, a fault in any cable included in the transmission, must first be traced, before the cause of the fault can be removed and the damage repaired.

This often entails time-consuming work and therefore imposes great demands on the ability of the network to cope with the load on the healthy section during this period.

Therefore, if the fault is not cleared after the first recloser, a double or triple shot reclosing is desired. If the fault still persists, the line is taken out of service.

Principle of Auto Reclosing

In this section, we will explain the basic principle of auto reclosing.

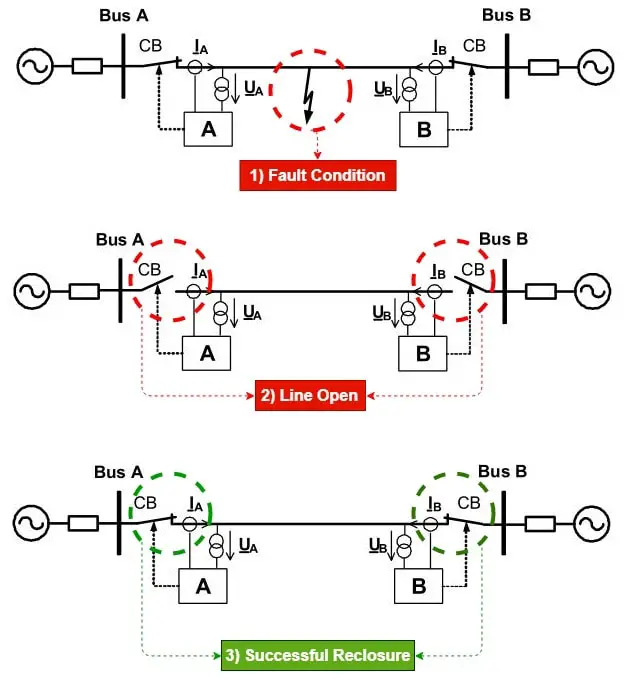

The figure below shows a typical transmission line connecting two parts of a network which are connected to the buses A and B.

In figure 1, a fault on the line is detected by the relays at both ends of the line measuring the currents IA and IB and the voltages UA and UB.

As soon as the relays A and B detect that the fault is on the protected line they will send a trip command to open the associated circuit breaker CB like shown in figure 2.

At this time the automatic reclosing functions integrated with the relays A and B start the dead time of the autoreclosure. During this dead time, the fault has the chance to extinguish.

After the dead time is expired, the automatic recloser function sends a close command to the associated circuit breaker. For transient faults, a successful recloser is mostly obtained with the first reclose cycle like shown in figure 3.

If the fault still persists the protective relays A and B will detect this and send a trip command again. A tree branch falling on a line, for instance, may need a second to reclose cycle to burn up by the arc when the line is re-energized.

For permanent faults caused by a broken conductor, the collapse of a line tower, trees falling onto a line or faults in cables a recloser is not able to clear the fault. Therefore it is important to detect this condition and send a final trip to the circuit breaker.

Based on experiences the most utilities apply automatic recloser with one reclose cycle only. This is because the increased chance to get a successful autorecloser does not justify the stress to circuit breakers and system due to additional close-open cycles under full fault current in case of permanent faults.

Single Phase and Three Phase Auto Reclosing

Automatic reclosing can be done as

- Single-phase Autoreclosing or

- Three-phase Autoreclosing

During a three-pole Autoreclosing, the line will be de-energized completely for all three phases even for a single-phase to ground fault.

A single-pole Autoreclosing, only de-energizes the faulted phase of a single-phase to ground fault.

Single Phase Auto Reclosing

Single-phase auto reclosing is resorted when a line to ground fault takes place and reclosed after a predetermined time.

For multiphase faults, all three phases are opened and recloser is not attempted.

In single-phase auto reclosing, the power can still be fed through the healthy phases to the system and the system is less unstable as compared to 3-phase reclosing.

Single pole auto reclosing increases the system stability because during the single-pole dead time energy can be transmitted through the two healthy phases.

Another advantage is that a single-pole auto recloser does not require a synchro-check before reclosing because both ends of the line are still synchronized through the two healthy phases.

Single pole auto recloser can lead to the occurrence of a secondary arc. During the single-pole, dead time capacitive and inductive coupling induces a voltage into the open phase conductor and feeds the secondary arc. The success of the single-pole auto recloser depends on the extinction of this secondary arc.

Three Phase Auto Reclosing

In case of three phase auto reclosing, all the three phases are opened independent of the type of fault, be it a single line to ground, or a line to line or 3-phase fault and are reclosed after a predetermined time.

Here during the opening period, no power can be transmitted and hence the system is liable to operate unstably.

Advantages of Single Pole Auto Reclosing

Today many utilities use single pole auto reclosure.

Single pole autorecloser has the following advantages compared to three-pole autorecloser:

- Transport of energy possible during the dead time via the two remaining wires.

- No synchronization needed before reclosing.

- Enhanced system stability and reliability.

Reference: https://library.e.abb.com/public/d9a7af4fb84394e8c125754d003393dc/RK85-201E_en_Auto-reclosing.pdf

Comments are closed.