A high voltage fuse is a type of electrical fuse specifically designed and rated for use in electrical systems with voltages exceeding 1,000 volts AC.

The low voltage fuses have limited current ratings and breaking capacities, making them suitable primarily for low voltage applications. Consequently, to address the needs of modern high voltage systems, specialized high voltage fuses have been developed.

Typically, high voltage (HV) fuses find application in safeguarding various equipment, including instrument transformers and small power transformers, as well as in power systems. HV fuses are typically employed in systems with voltage levels ranging from 1500V to 138,000V.

The fuse components within HV fuses are crafted from materials such as copper, silver, or occasionally tin. This selection of materials ensures the fuses deliver consistent and reliable performance.

High Voltage Vs Medium Voltage Fuse

Before we proceed, let’s clarify the distinction between “high-voltage” fuses and “medium-voltage” fuses.

The classification of “high-voltage” can vary based on different standards. For instance, some standards like ANSI C84.1 consider both system voltages above 1,000 V as either medium-voltage or high-voltage. In this context, “medium-voltage” typically refers to voltage levels below 100,000 V or, in some cases, even lower, depending on the specific standard. Conversely, “high-voltage” encompasses voltage values exceeding this threshold.

It’s important to note that while we use the term “high-voltage fuse” colloquially, technically, IEEE and IEC fuse standards do not officially recognize or classify fuses as “medium-voltage fuses.” Instead, they categorize fuses based on their voltage ratings and characteristics without using the specific term “medium-voltage fuse.”

Types of High Voltage Fuses

Some of the high voltage fuses are presented below:

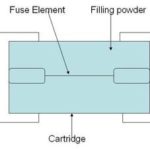

1. Cartridge Type Fuse

The high voltage cartridge type fuse shares a construction resemblance with low voltage cartridge fuses but features unique design elements. Some variations incorporate fuse elements wound in a helix shape to counteract corona effects, particularly at high voltages. In other designs, dual fuse elements run in parallel, with one being of low resistance (silver) and the other of high resistance (tungsten wire).

During normal load conditions, the low-resistance element handles the standard current. However, when a fault occurs, the low-resistance fuse element blows out, and the high-resistance element steps in. This high-resistance element reduces the short-circuit current and ultimately breaks the circuit.

High Voltage cartridge type fuses find application in systems up to 33 kV, with a breaking capacity of approximately 8700 A at that voltage.

Fuses with ratings such as 200 A at 6.6 kV and 50 A at 33 kV are also available for various high voltage scenarios.

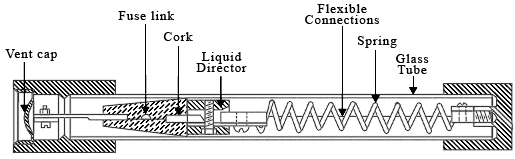

2. Liquid Type Fuse

Liquid type fuses are filled with carbon tetrachloride and offer a broad range of applications in high voltage systems. They can be employed in circuits with a rated current of up to approximately 400 A in systems with voltages of 132 kV or higher, boasting breaking capacities of around 6100 A.

These fuses are entirely filled with carbon tetrachloride, which is also sealed at both ends of the caps. When current flow exceeds the allowable limit, triggering a fault, the fuse element is blown out. The liquid within the fuse acts as an effective arc extinguishing medium, particularly suitable for High Rupturing Capacity (HRC) fuse types. Liquid type fuses can be used to protect transformers and provide auxiliary protection to circuit breakers.

3. Metal Clad Fuse

Metal clad, oil-immersed fuses represent an innovative solution designed to serve as a substitute for traditional oil circuit breakers.

These fuses are engineered to handle extremely high voltage situations with competence. They perform admirably even when faced with short-circuit conditions that approach their rated capacity.

4. Expulsion Type High Voltage (HV) Fuse

Expulsion type fuses find wide utility in safeguarding feeders and transformers, mainly due to their cost-effectiveness. These fuses are specifically designed for 11kV applications, boasting an impressive breaking capacity of up to 250 MVA.

The construction of this fuse comprises an open-ended cylinder made from synthetic resin-bonded paper. Inside the cylinder, the fuse elements are carefully positioned, and the tube ends are connected to appropriate equipment at both ends. In operation, the arc generated is expelled into the inner lining of the cylinder, where the resulting gases effectively extinguish the arc.

| Type of High Voltage Fuse | Voltage Rating | Rated Current | Breaking Capacity |

|---|---|---|---|

| Cartridge Type Fuse | Up to 33 kV | Varies | About 8700 A |

| Liquid Type Fuse | 132 kV or above | Up to 400 A | Approximately 6100 A |

| Metal Clad Fuse | Very high | Varies | Varies |

Function of HV Fuses

High and low current interruption are the two primary functions of high voltage (HV) fuses, and understanding how they perform these functions is essential.

High Current Interruption: HV fuses are primarily designed to respond to high currents, typically referred to as “short-circuit” currents. During such events, most of the electrical load is bypassed, and the current can soar to very high levels. The effectiveness of fuses in handling high currents varies significantly, and this plays a vital role in selecting the right fuse for a specific application. Fuses are categorized as either “current-limiting” or “non-current-limiting” based on their behavior during high-current events.

It’s important to note that most non-current-limiting fuses are commonly known as “expulsion fuses” since they belong to this category.

Low Current Interruption (Overload): The second function of high voltage fuses is to respond to moderately excessive currents, often referred to as “overload” currents. These currents can be up to approximately 10 times the rated current of the fuse. However, not all fuses are engineered for this type of operation. Some fuses are designed specifically to function only at high currents and may experience arcing at low currents. In such cases, a secondary device is coordinated to interrupt the current, potentially resulting in physical damage to the fuse.

Fuses are classified in various ways based on their responses to both high and low currents. While all current-limiting fuses excel at handling high-current situations, they are further categorized as “backup,” “general-purpose,” or “full-range” based on their capability to interrupt lower currents.

Understanding how fuses react under different current conditions is crucial for selecting the appropriate fuse for a specific application.

Comments are closed.