Gas-insulated substations (GIS) have been used in power systems over the last three decades because of their high reliability, easy maintenance, small ground space requirement, etc. This article is an introduction to Gas-insulated Substations.

Gas Insulated Substation (GIS) also called SF6 Gas Insulated Metalclad Switchgear is preferred for 12kV, 36kV, 72.5kV, 145 kV, 245 kV, 420 kV, and above voltages.

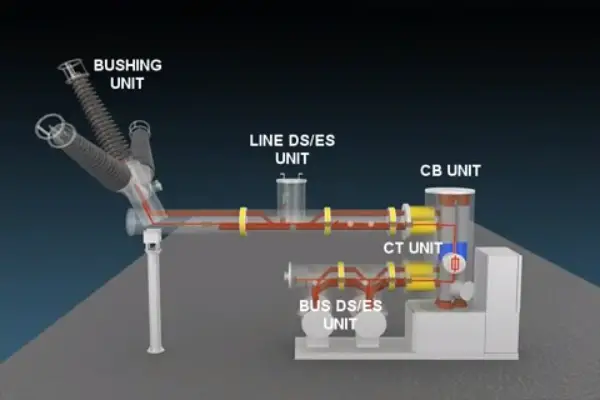

In a GIS substation, the various equipment like Circuit Breakers, Bus bars, Isolators, Load break switches, Current transformers, Voltage transformers, Earthing switches, etc. are housed in separate metal-enclosed modules filled with SF6 gas. The SF6 gas provides the phase to ground insulation.

As the dielectric strength of SF6 gas is higher than air, the clearances required are smaller. Hence the overall size of each equipment and the complete sub-station is reduced.

The various modules are factory assembled and are filled with SF6 gas. Thereafter, they are taken to site for final assembly.

SF6 Gas Insulated Substations are compact and can be installed conveniently on any floor of a multi-storeyed building or in an underground substation. As the units are factory assembled, the installation time is substantially reduced.

Such installations are preferred in composition cities, industrial townships, hydro stations where land is very costly.

The higher cost of SF6 insulated switchgear is justified by saving to the reduction in floor-area requirement.

SF6 insulated switchgear is also preferred in heavily polluted areas where dust, chemical fumes and salt layers can cause frequent flashovers in conventional outdoor sub-stations.

The GIS require less number of lightning arresters than a conventional one. This is mainly because of its compactness.

Why SF6 is Used?

SF6 has two to three times the insulating ability of air at the same pressure. SF6 is about 100 times better than air for interrupting arcs.

Read more about the advantages of SF6 gas in SF6 Circuit Breaker.

Inside a Gas Insulated Substation (Video)

Advantages of Gas Insulated Substations

Compactness of GIS

Protection from pollution

The construction of the building need not be very strong like conventional power houses.

Reduced Switching over voltages

Reduced Installation Time

Superior Arc Interruption

Gas Pressure

Increased Safety

Demerits of GIS

- High cost compared to conventional outdoor sub-station.

- Excessive damage in case of internal fault. Long outage periods as repair of damaged part at site may be difficult.

- Requirements of cleanliness are very stringent. Dust or moisture can cause internal flashovers.

- Such sub-stations generally indoor. They need a separate building. This is generally not required for conventional outdoor sub-stations. Procurement of gas and supply of gas to site is problematic. Adequate stock of gas must be maintained.

Comments are closed.