Before going to the operation and characteristics of split-phase induction motor we should first understand why single phase induction motor is not self-starting.

To make a single-phase induction motor self-starting, we should somehow produce a rotating magnetic field. This may be achieved by converting a single-phase supply into two-phase supply through the use of an additional winding.

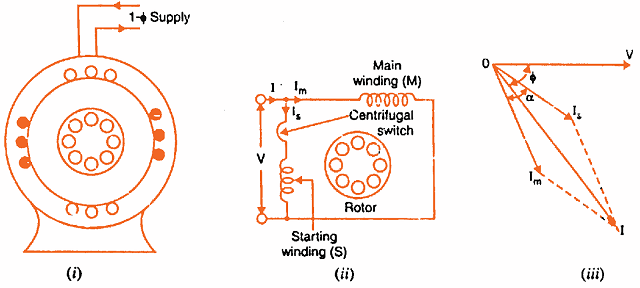

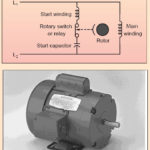

In a split-phase induction motor, the additional winding is known as auxiliary winding or starting winding. The constructional features of split-phase induction motors are well explained below.

The two windings are so designed that the starting winding S has a high resistance and relatively small reactance while the main winding M has relatively low resistance and large reactance as shown in the schematic connections in the figure.

Consequently, the currents flowing in the two windings have a reasonable phase difference (25° to 30°) as shown in the phasor diagram in the figure given above. Hence the motor behaves like a two-phase motor. These two currents produce a revolving flux and hence make the motor self-starting.

A centrifugal switch is connected in series with the starting winding. Its function is to automatically disconnect the starting winding from the supply when the motor has reached 70 to 80 percent of its full load speed.

The resistance of starting winding may be increased in two ways :

- by connecting a high resistance in series with it or

- by choosing high resistance fine copper wire for winding purposes.

Working of Split Phase Induction Motor

When the two stator windings are energized from a single-phase supply, the main winding carries current Im while the starting winding carries current Is.

Since main winding is made highly inductive while the starting winding highly resistive, the currents Im and Is have a reasonable phase angle a (25° to 30°) between them as shown in Figure.

Consequently, a weak revolving field approximating to that of a 2-phase machine is produced which starts the motor.

The starting torque is given by;

where k is a constant whose magnitude depends upon the design of the motor.

- When the motor reaches about 75% of synchronous speed, the centrifugal switch opens the circuit of the starting winding.

- The motor then operates as a single-phase induction motor and continues to accelerate until it reaches the normal speed. The normal speed of the motor is below the synchronous speed and depends upon the load on the motor.

The direction of rotation of such motors can be reversed by reversing the connection of any one of the stator windings ( not both ). The rotating magnetic field gets reversed and hence the motor rotates in the opposite direction. For this purpose four leads are brought outside the frame.

Characteristics of Split Phase Induction Motor

- The starting torque is 150 to 200 percent of the full load torque with a starting current of 6 to 8 times the full load current.

- Due to their low cost, split-phase induction motors are the most popular single-phase motors in the market.

- Since the starting winding is made of fine wire, the current density is high and the winding heats up quickly. If the starting period exceeds 5 seconds, the winding may burn out unless the motor is protected by built-in-thermal relay. This motor is, therefore, suitable where starting periods are not frequent.

- An important characteristic of these motors is that they are essentially constant-speed motors. The speed variation is 2-5% from no-load to full load. For this reason, they are usually regarded as constant-speed motors.

- These motors are suitable where a moderate starting torque is required and where starting periods are infrequent

- e.g., to drive:

- (a) fans

- (b) washing machines

- (c) oil burners

- (d) small machine tools etc.

- e.g., to drive:

The power rating of such motors generally lies between 60 W and 250 W.

.png)

Comments are closed.