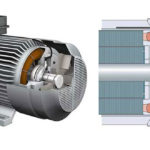

Motors are used everywhere in industrial environments and they are becoming increasingly complex and technical, sometimes making it a challenge to keep them running at peak performance.

It’s important to remember that the causes of motor and drive issues are not confined to a single domain of expertise–both mechanical and electrical issues can lead to motor failure and being armed with the right knowledge can mean the difference between costly downtime and improved asset uptime.

Winding insulation breakdown and bearing wear are the two most common causes of motor failure, but those conditions arise for many different reasons. This article demonstrates how to detect the most common causes of winding insulation and bearing failure in advance.

Transient Voltage

Transient voltages can come from a number of sources either inside or outside of the plant. Adjacent loads turning on or off, power factor correction capacitor banks or even distant weather can generate transient voltages on distribution systems. These transients, which vary in amplitude and frequency, can erode or cause insulation breakdown in motor windings.

Finding the source of these transients can be difficult because of the infrequency of the occurrences and the fact that the symptoms can present themselves in different ways. For example, a transient may appear on control cables that don’t necessarily cause equipment damage directly, but may disrupt operations.

Impact: Motor winding insulation breakdown leads to early motor failure and unplanned downtime.

Voltage Imbalance

Three-phase distribution systems often serve single-phase loads. An imbalance in impedance or load distribution can contribute to imbalance across all three of the phases. Potential faults may be in the cabling to the motor, the terminations at the motor, and

potentially the windings themselves.

This imbalance can lead to stresses in each of the phase circuits in a three-phase power system. At the simplest level, all three phases of voltage should always have the same magnitude.

Impact: Imbalance creates excessive current flow in one or more phases that then increases operating temperatures–leading to insulation breakdown.

Harmonic Distortion

Simply stated, harmonics are any unwanted additional source of high frequency AC voltages or currents supplying energy to the motor windings. This additional energy is not used to turn the motor shaft but circulates in the windings and ultimately contributes to internal energy losses. These losses dissipate in the form of heat, which, over time, will deteriorate the insulation capability of the windings.

Some harmonic distortion of the current is normal on any part of the system serving electronic loads. To start investigating harmonic distortion, use a power quality analyzer to monitor electrical current levels and temperatures at transformers to be sure that they are not overstressed. Each harmonic has a different acceptable level of distortion, which is defined by standards such as IEEE 519-1992.

Impact: Decrease in motor efficiency results in added cost and an increase in operating temperatures.

Reflections on drive output PWM signals

Variable frequency drives employ a pulse width modulation (PWM) technique to control the output voltage and frequency to a motor. Reflections are generated when there is an impedance mismatch between the source and load. Impedance mismatches can occur as a result of improper installation, improper component selection or equipment degradation over time. In a motor drive circuit, the peak of the reflection could be as high as the DC bus voltage level.

Impact: Motor winding insulation breakdown leads to unplanned downtime.

Sigma current

Sigma currents are essentially stray currents that circulate in a system. The sigma currents are created as a result of the signal frequency, voltage level, capacitance and inductance in conductors.

These circulating currents can find their way through protective earth systems causing nuisance tripping or in some cases excess heat in windings. Sigma current can be found in the motor cabling and is the sum of the current of the three phases at any one point in time.

In a perfect situation, the sum of the three currents would equal zero. In other words, the return current from the drive would be equal to the current to the drive. Sigma current can also be understood as asymmetrical signals in multiple conductors that can capacitively couple currents into the ground conductor.

Impact: Mysterious circuit trip due to protective earth current flow.

Operational overloads

Motor overload occurs when a motor is under excessive load. The primary symptoms that accompany a motor overload are excessive current draw, insufficient torque and overheating.

Excessive motor heat is a major cause of motor failure. In the case of an overloaded motor individual motor components including bearings, motor windings, and other components may be working fine, but the motor will continue to run hot. For this reason, it makes sense to begin your troubleshooting by checking for motor overload.

Because 30 % of motor failures are caused by overloading, it is important to understand how to measure for and identify motor overloading.

Impact: Premature wear on motor electrical and mechanical components leading to permanent failure.