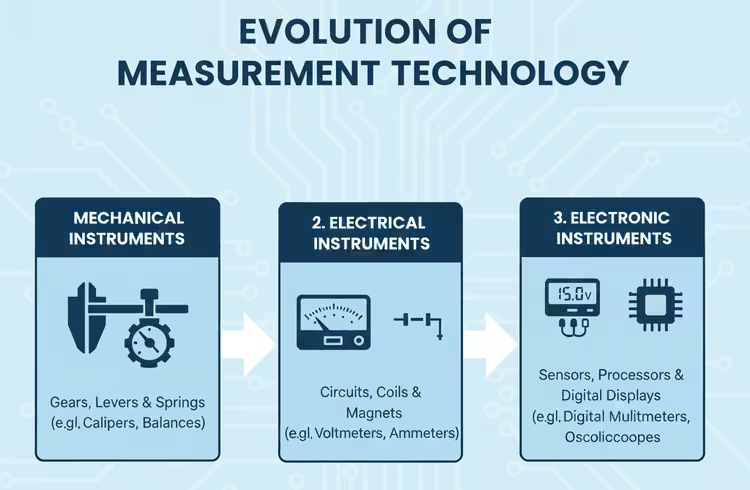

Measurement technology has evolved significantly—from simple mechanical devices to highly advanced electronic instruments. Modern engineering depends heavily on accurate, fast, and reliable measurement systems for monitoring, control, automation, and scientific analysis.

This article explains mechanical, electrical, and electronic instruments, their working principles, advantages, disadvantages, and applications.

Understanding Measurement Instruments

From early mechanical devices to today’s digital systems, most measuring instruments—regardless of type—consist of three essential components:

- Detector – Senses or detects the input quantity

- Intermediate Device – Transfers, modifies, or converts the signal

- Indicator / Recorder / Storage unit – Displays or stores the measured value

The evolution of measurement technology can be divided into three major phases:

- Mechanical instruments

- Electrical instruments

- Electronic instruments

1. Mechanical Instruments

Mechanical instruments were the earliest measurement tools used by humans. Their basic working principles are still used in many devices today—such as pressure gauges, Bourdon tubes, and spring balances.

Characteristics of Mechanical Instruments

- Highly reliable under static or slow-changing conditions

- Rugged construction

- Do not require an external power supply

However, they cannot respond rapidly to fast-changing or dynamic signals.

Why Mechanical Instruments Are Slow

Mechanical systems contain rigid, heavy, and bulky moving parts.

These parts have high mass → high inertia → slow response.

For example:

- Measuring a slowly varying pressure is easy with a mechanical gauge

- Measuring a 50 Hz AC voltage is impossible with purely mechanical devices

Drawbacks

- Poor dynamic response

- Not suitable for high-frequency measurements

- Generate noise (mechanical vibrations)

- Limited sensitivity

Mechanical tools are still widely used in low-frequency or static applications such as pressure measurement, dimensional inspection, and force measurement.

2. Electrical Instruments

Electrical instruments represent the next major step in instrument development.

They provide faster response compared to mechanical instruments and are widely used in electrical engineering, power systems, and industrial applications.

(Related article: Types of Analog Measuring Instruments)

How Electrical Instruments Work

These instruments convert the detector output into an electrical signal, which is then displayed by a meter movement.

However, traditional electrical instruments still rely on a mechanical pointer movement, which again introduces inertia.

Time Response

- Some high-performance galvanometers can follow 50 Hz variations

- Industrial electrical recorders typically respond in 0.5 to 24 seconds

- Still too slow for high-speed or transient measurements

Advantages

- Faster than mechanical instruments

- More sensitive and easier to read

- Suitable for steady-state and low-frequency measurements

Limitation

The mechanical moving-coil or moving-iron mechanism restricts high-speed performance.

3. Electronic Instruments

With the need for high-speed, high-accuracy, and dynamic measurement, electronic instruments became essential in modern engineering.

These devices use semiconductor components, amplifiers, and high-speed circuits to provide extremely rapid response—sometimes in nanoseconds.

(Learn more: Working of Cathode Ray Oscilloscope (CRO))

Why Electronic Instruments Are Fast

The only moving particles involved are electrons, which have negligible mass → almost zero inertia → exceptionally fast response.

For example:

- A CRO can track signals with a response time of a few nanoseconds (10⁻⁹ s)

Major Advantages of Electronic Instruments

- High sensitivity – Can detect very weak signals

- Especially useful for bio-instrumentation, where signals are < 1 mV

- Fast response time – Suitable for transient, dynamic, and high-frequency signals

- Low power consumption

- Lightweight and compact

- High reliability

- Greater flexibility

- Remote indication possible – Critical for hazardous environments

- Suitable for non-electrical measurements through transducers

(Related: Phased Array Transducer: Applications and Advantages)

Power Amplification

Electronic amplifiers play a major role by providing power gain.

They allow weak signals to operate devices such as:

- CROs

- Magnetic tape recorders

- Stylus-type recorders

- Bio-signal monitoring equipment

Hydraulic or pneumatic systems can also amplify signals but are far slower than their electronic counterparts.

Applications of Electronic Instruments

Electronic measurement technology has transformed modern engineering sectors:

1. Communication Systems

From radio to microwave to satellite communication, electronic instruments are essential for signal detection, modulation, transmission, and processing.

2. Power & Energy Systems

Used in:

- Power quality monitoring

- Fault detection

- High-speed relays

- Electronic meters

(See: Current Transformers (CT) Working)

3. Industrial Automation

Used for:

- Real-time monitoring

- Process control

- Data acquisition systems (DAQ)

4. Computing Systems

Computers demand extremely fast response, achievable only through electronic instrumentation.

Summary: Mechanical vs Electrical vs Electronic Instruments

| Feature | Mechanical | Electrical | Electronic |

|---|---|---|---|

| Response Time | Slow | Moderate | Very Fast |

| Moving Parts | Heavy, bulky | Light mechanical | Only electrons |

| Accuracy | Moderate | Good | Very High |

| Dynamic Measurement | Poor | Limited | Excellent |

| Power Requirement | None | Low | Very Low |

| Typical Use | Pressure, force, static measurements | Electrical quantities | High-speed, transient signals |

| Examples | Bourdon gauge, spring balance | Ammeter, voltmeter | CRO, digital meters |

Electronic instruments offer clear advantages in sensitivity, speed, weight, flexibility, and reliability, making them indispensable in modern engineering industries.