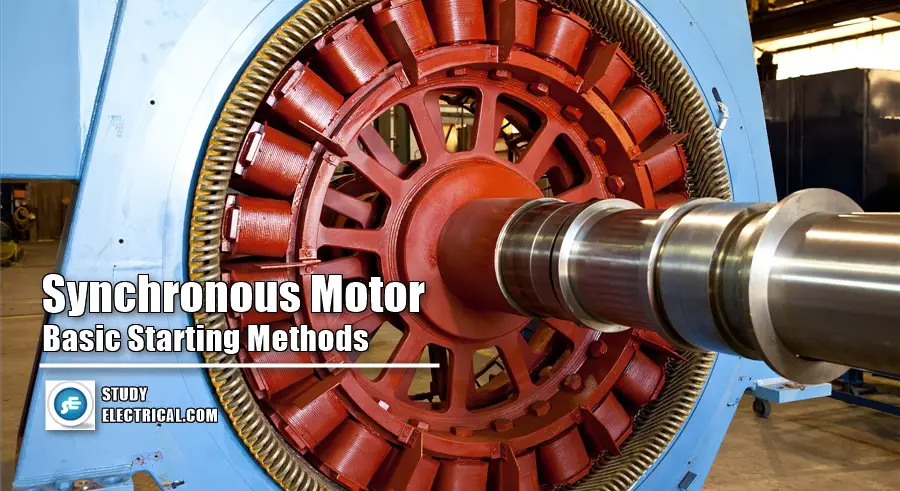

Synchronous motors are not self-starting. Some additional devices should be used to start the motor. Basically, there are two methods for starting synchronous motors:

- Induction motor starting (Damper winding)

- Auxiliary motor starting.

Damper Winding Starting

Most of the synchronous motors have a salient pole structure. A winding consisting of heavy copper bars is installed in slots in the pole faces. These bars are all shorted together at both ends of the rotor.

When 3-phase supply is fed to the stator, a rotating magnetic field is produced in the air gap which induces currents in the bars which further produces flux. The interaction of the fluxes produces torque in the direction of field rotation. In other words, the motor is started as an induction motor, the bars in the pole face slots forming a sort of squirrel cage rotor.

Induction motor action will bring the motor to nearly synchronous speed. At synchronous speed, there is no relative motion between the poles of the air gap field and the pole face bars. No current is induced in the bars at synchronous speed, and no torque would be produced by them. However, the maximum speed developed on induction motor action is very close to the synchronous speed and the rotor falls into step when the dc field current is switched on.

Induction motor action will bring the motor to nearly synchronous speed. At synchronous speed, there is no relative motion between the poles of the air gap field and the pole face bars. No current is induced in the bars at synchronous speed, and no torque would be produced by them. However, the maximum speed developed on induction motor action is very close to the synchronous speed and the rotor falls into step when the dc field current is switched on.

The field winding terminals are usually shorted through a resistor during starting until such time that the field is excited. This has two advantages.

- First, it protects the slip ring insulation from the high ac voltage induced in the field during starting.

- Second, the current circulating in the field winding would provide a small additional accelerating torque.

Auxiliary Motor Starting

The auxiliary motor may be a dc shunt motor or an induction motor having the same number of poles as the synchronous motor or two poles less as compared to synchronous motor. The job of the auxiliary motor is to bring the synchronous motor to synchronous speed or near synchronous speed.

The auxiliary motor is mechanically coupled to the synchronous motor. No load is put on the synchronous motor during starting. Therefore, the auxiliary motor has to overcome only the inertia of the synchronous motor and may have its rating much smaller than that of the synchronous motor is started.

When the speed is near synchronous speed, the 3-phase supply is switched on to the armature and DC supply to the field circuit of the synchronous motor. The synchronous motor pulls into step, its speed rises to synchronous speed and it continues to run at this speed.

If the induction motor has two poles less than the synchronous motor, the induction motor speed is higher than the synchronous speed of the synchronous motor. Once the higher speed is attained, the supply to the induction motor is switched off and 3-phase supply to the synchronous motor is switched on.

When the speed of the synchronous motor almost equals the synchronous speed, it’s field winding is energized. The synchronous motor pulls into step and starts running at synchronous speed. However, in modern days this method of starting is hardly used. It is mainly the damper winding which is utilised for starting the synchronous motor.

When the speed of the synchronous motor almost equals the synchronous speed, it’s field winding is energized. The synchronous motor pulls into step and starts running at synchronous speed. However, in modern days this method of starting is hardly used. It is mainly the damper winding which is utilised for starting the synchronous motor.