A stepper motor is an electromechanical device which converts electrical pulses into discrete mechanical movements.

The shaft or spindle of a stepper motor rotates in discrete step increments when electrical command pulses are applied to it in the proper sequence. The motors rotation has several direct relationships to these applied input pulses.

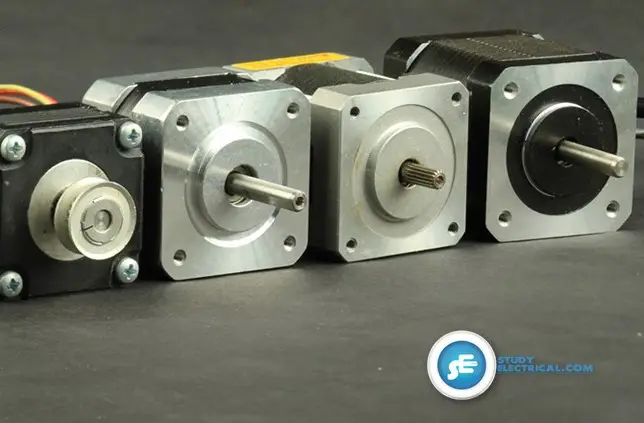

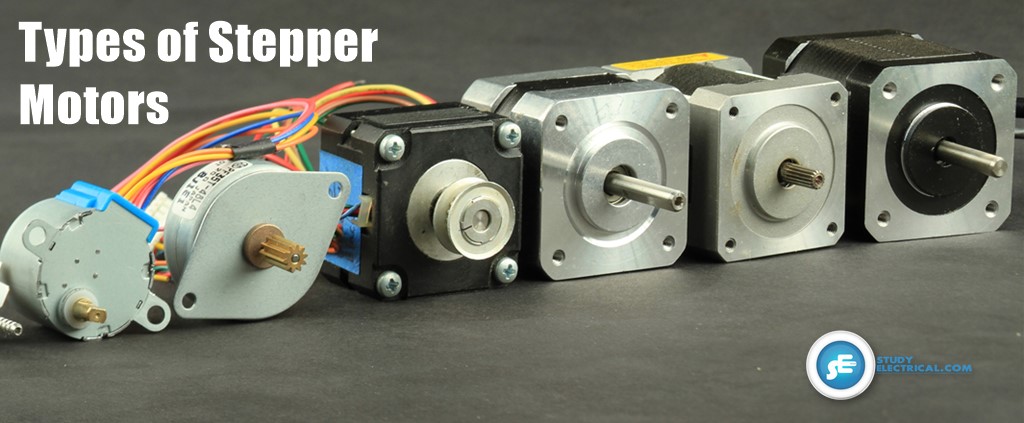

Types of Stepper Motor

There are three basic stepper motor types. They are :

- Variable Reluctance Stepper Motor

- Permanent Magnet Stepper Motor

- Hybrid Stepper Motor

These may be either 2-phase bipolar, or 4-phase unipolar. We will discuss unipolar and bipolar stepper motors later in another article.

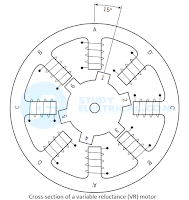

Variable Reluctance Stepper Motor

This type of stepper motor has been around for a long time. It is probably the easiest to

understand from a structural point of view.

The figure shows a cross section of a typical Variable Reluctance stepper motor. This type of motor consists of a soft iron multi-toothed rotor and a wound stator.

When the stator windings are energized with DC current the poles become magnetized. Rotation occurs when the rotor teeth are attracted to the energized stator poles.

Permanent Magnet Stepper Motor

Often referred to as a “tin can” or “canstock” motor the permanent magnet step motor is a low cost and low-resolution type motor with typical step angles of 7.5° to 15° (48 – 24 steps/revolution).

PM motors as the name imply have permanent magnets added to the motor structure. The rotor no longer has teeth as with the VR motor. Instead, the rotor is magnetized with alternating north and south poles situated in a straight line parallel to the rotor shaft.

These magnetized rotor poles provide an increased magnetic flux intensity and because of this the PM motor exhibits improved torque characteristics when compared with the VR type.

Hybrid Stepper Motor

The hybrid stepper motor combines the best features of both the PM and VR type stepper motors. The rotor is multi-toothed like the VR motor and contains an axially magnetized concentric magnet around its shaft.

The teeth on the rotor provide an even better path which helps guide the magnetic flux to preferred locations in the airgap. This further increases the detent, holding and dynamic torque characteristics of the motor when compared with both the VR and PM types.