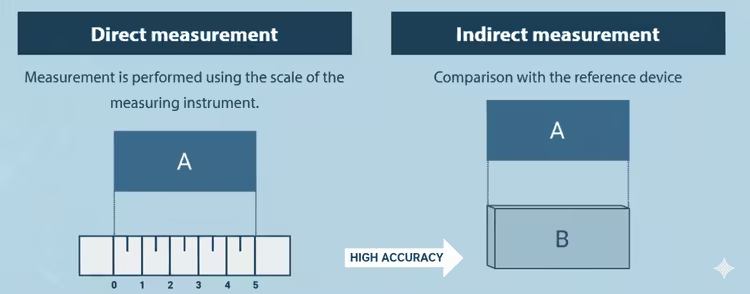

Measurement is fundamental in science, engineering, and industrial systems. Whether determining the length of a component or calculating electrical resistance, engineers rely on direct and indirect measurement methods to obtain accurate results.

This article explains both methods, includes direct and indirect measurement examples, and clearly highlights the difference between direct and indirect measurement.

What Is Direct Measurement?

Direct measurement refers to determining a quantity by directly comparing it with a physical standard using an instrument.

The measurand (unknown quantity) is observed without additional calculations.

A standard is a physical embodiment of a unit—such as metre, kilogram, or second.

If you measure the length of a metal rod using a steel ruler, the scale reading directly gives the value of the rod’s length.

Engineers frequently perform direct measurements during practical work, calibration, and basic inspections.

Characteristics of Direct Measurement

- Simple and straightforward

- Limited accuracy due to human error (parallax, reading mistakes)

- Mostly used when the quantity is easily accessible

- Less suitable for complex engineering measurements

Direct Measurement Examples

- Measuring length with a Vernier caliper or micrometer

- Measuring temperature with a thermometer

- Measuring mass using a balance

- Measuring voltage using a voltmeter

- Measuring time with a stopwatch

Although direct measurements are convenient, they are often not sufficient for high-precision engineering applications.

What Is Indirect Measurement?

Indirect measurement determines an unknown quantity using mathematical relationships or instrument-derived data.

This method is widely used in engineering because:

- Direct access to measurands is often impossible

- Higher precision is required

- Automated systems depend on sensor outputs, not manual readings

Modern measurement systems rely heavily on indirect techniques, often involving transducers, sensors, and signal conditioning circuits.

(Learn more: Introduction to Electrical Measuring Instrument)

Characteristics of Indirect Measurement

- Higher accuracy and sensitivity

- Less dependent on human judgement

- Requires formulas or derived values

- More suitable for industrial and electrical engineering applications

Indirect Measurement Examples

- Calculating electrical resistance using Ohm’s Law: R = V/I

(Related article: Ohm’s Law Explained) - Determining flow rate using differential pressure

- Measuring height of tall structures using trigonometry

- Calculating density using mass and volume

- Measuring power factor using measured voltage and current

- Using instrument transformers for indirect current & voltage measurement

(Read: Current Transformers (CT): Working & Construction)

Indirect measurement is preferred in almost every modern electrical and electronic system.

Difference Between Direct and Indirect Measurement

Here is a clear comparison for engineering students and professionals:

| Feature | Direct Measurement | Indirect Measurement |

|---|---|---|

| Definition | Measuring the quantity directly using an instrument | Determining the quantity using formulas or related measurements |

| Computation | No calculations required | Requires mathematical processing |

| Human Influence | High | Low |

| Accuracy | Moderate | High |

| Example Tools | Ruler, thermometer, balance | CT/PT, multimeter (for derived values), DP flow meter |

| Engineering Usage | Limited | Widely used |

| Use Case | When measurand is directly accessible | When direct measurement is impractical or inaccurate |

Real-World Engineering Applications

- In substation design, electrical quantities like current and voltage are often measured indirectly using CTs and PTs.

(See: Electrical Substation Equipment) - Transformer impedance, load, and efficiency are evaluated using indirect formulas.

(Related: Percentage Impedance of Transformer) - In power systems, most performance parameters (fault current, line losses, power factor) are obtained through indirect measurement techniques.

Summary

- Direct measurement involves directly reading a value from an instrument.

- Indirect measurement calculates the value using related measurable parameters.

- Engineering heavily depends on indirect measurement due to higher accuracy, automation, and practicality.

- Understanding both methods is essential for instrumentation, electrical engineering, and industrial systems.