There are several types of flow meters in the market these days. Most of them use complicated technologies to measure the volumetric flow, linear, nonlinear, and the mass flow rate of a fluid flowing through a pipeline.

Fluids come with different properties. Each requires different metering systems to ensure precise and accurate measurements. Along with turbine and differential pressure flow meters, electromagnetic flowmeters are one of the most conventional among others.

The name electromagnetic flow meter is quite understandable as it uses electromagnetic induction to measure the flow rate of a fluid.

What is an Electromagnetic Flow Meter?

By using Faraday’s Law, electromagnetic flow meters measure the flow rate of conductive liquid that passes through a pipeline, which has sensors. This conductive fluid will send out a magnetic field. This region is essential in determining the flow rate, which will then be sensed by the electrodes that are found inside the tube walls.

The voltage generated by the fluid’s flow is directly proportional to the fluid’s pressure. In a simpler explanation, the faster the liquid goes through a pipe, the more voltage it will generate. The voltage signal will then be processed by the electromagnetic flowmeter to determine the flow rate of the liquid.

An electromotive force causes electromagnetic induction by the use of an electrical conductor through the changes in the magnetic field. In short, as a conductive material and magnetic field continue to move in relative with each other, a voltage will be created.

According to the law of electromagnetic induction, the fluid itself should be conducive to be able to produce a voltage through a magnetic field. It means that electromagnetic flowmeters are not applicable to measure non-conductive liquids like alcohol, hydrocarbons, deionized water, and other nonaqueous solutions.

Benefits of Electromagnetic Flow Meters

One of the most beneficial features of electromagnetic flowmeters is their lack of moving parts. The electrodes or the sensors are built in-line, meaning, they would not affect the flow of the fluid in any way possible. Also, its absence of moving parts makes it easier to maintain as you wouldn’t be worried about maintenance problems that are common in flow meters with moving parts.

Also, electromagnetic flowmeters measure the volumetric flow of the fluid. The data, which the flowmeter will gather from measuring the fluid’s discharge, will not be affected by the fluid’s other properties, including its temperature, density, viscosity, and pressure. This also means that when the electromagnetic flow meter is calibrated, it can still measure other types of conductive fluids without any concerns about additional calibration and adjustments.

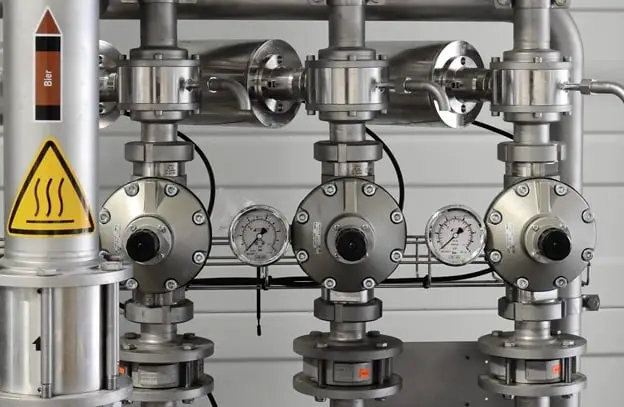

Another benefit electromagnetic flow meters bring is that they can also measure fluids that have inconsistencies and contaminants, such as the presence of bubbles, solid particles, and fluid fibers. The measurement of electromagnetic flowmeter is based directly on how the charged particles move through the pipeline lined with electrodes, meaning it can measure fluids with inconsistencies like mud, seawater, or juices.

Disadvantages

Electromagnetic flow meters are not without drawbacks, though. There are several of them, and they should be considered before deciding whether to use this type of flow meter.

The application of electromagnetic flowmeters is minimal. It can only measure conductive fluid, but nor water for heat treatment and gas. Also, the electrode lining installed within the pipe must be considered under high pressure.

The flow meter determines the flow rate in the working state by getting the measurement of the speed of the conductive fluid. One of the requirements for liquid media is to measure the mass flow first. The flow rate of the fluid should be directly related to the fluid’s density.

Different fluid media have differing densities, which can vary with temperature. If the electromagnetic flowmeter converter doesn’t consider the fluid’s mass, giving the volumetric flow at the fluid’s average temperature can lead to inaccuracy in the measurement.

The commissioning, requirements, and installation of electromagnetic flowmeters can be more complicated than other flow meters. The converter and transmitter should be used at the same time and should not be used with different instruments. Upon the flow meter’s installation, the selection of the specific installation and commissioning should always be carried out strictly and based on the product’s specifications. The site of the installation should be free from strong magnetic fields and causes of vibrations.

The piping and the transmitter should be in good contact and must be well-grounded during the installation process. Upon using, the remaining gases should be aired out to avoid it harming the measurement being made from the fluid.

Takeaway

Electromagnetic flow meters from smart measurements are your best choice if you want highly precise measurements in specific fluids that other types of metering systems cannot achieve. As the name suggests, electromagnetic flow meters measure the flow rate of fluid with the use of electromagnetic induction. As such, using electromagnetic flowmeters is optimal if you want to measure the flow rate of conductive fluids.

Comments are closed.