MCB or Miniature Circuit Breaker is an electromechanical device that protects an electric circuit from an overcurrent. The overcurrent in an electrical circuit may result from short circuit, overload or faulty design. This article explains different MCB types, their working and trip curves.

In short, MCB is a device for overload and short circuit protection. They are used in residential & commercial areas. Just like we spend the time to make a thorough check before buying appliances like washing machines or refrigerators, we must also research about Miniature Circuit Breakers.

An MCB is a better alternative to a Fuse since it does not require replacement once an overload is detected. Unlike a fuse, an MCB can be easily operated and thus offers improved operational safety and greater convenience without incurring a large operating cost. They are used to protect lower current circuits and have the following specifications

- Current rating – Amperes

- Short Circuit Rating – Kilo Amperes (kA)

- Operating Characteristics – B, C, D, Z or K Curves

Don’t confuse Miniature circuit breaker with MCCB (Moulded Case Circuit Breaker) or GFCI (Ground Fault Circuit Breaker).

A Miniature Circuit Breaker is a switchgear which is usually available in the range of 0.5A to 100A. Its Short circuit rating is given in Kiloamps (kA), and this indicates the level of its ability to work.

For example, a domestic MCB would normally have a 6kA fault level, whereas one used in an industrial application may need a unit with a 10kA fault capability.

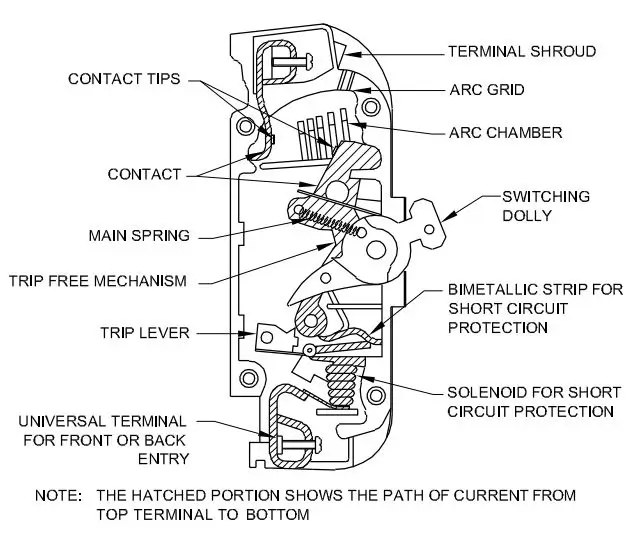

Working Principle of Miniature Circuit Breaker (MCB)

MCB’s are protective devices that are made to break the circuit in case of overload or short circuit.

The working of a miniature circuit breaker in case of overload and short circuit fault is,

- For Overload protection, they have a Bi-metallic strip which causes the circuit to open.

- For Short circuit protection, it has an electromagnetic kind of thing.

There is two arrangement of operation of a miniature circuit breaker.

- Due to the thermal effect of over electric current

- Due to the electromagnetic effect of overcurrent.

The thermal operation of the miniature circuit breaker is achieved with a bimetallic strip. Whenever continuous over electric current flows through MCB, the bimetallic strip is heated and deflects by bending.

This deflection of bimetallic strip releases the mechanical latch. As this mechanical latch is attached with the operating mechanism, it causes to open the miniature circuit breaker contacts.

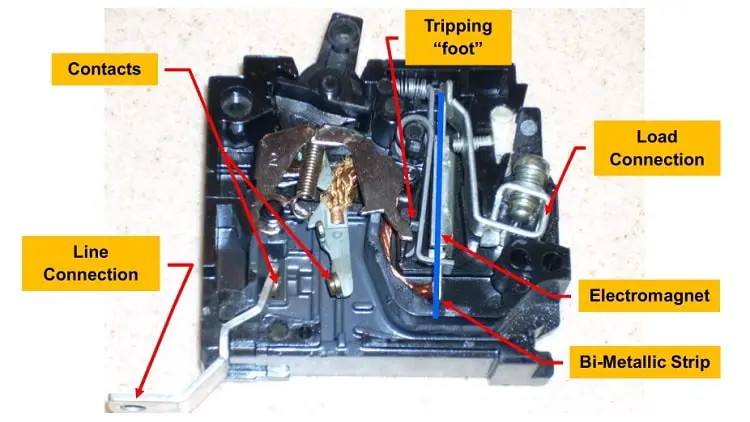

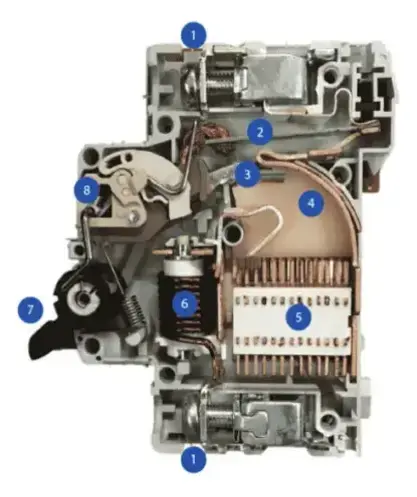

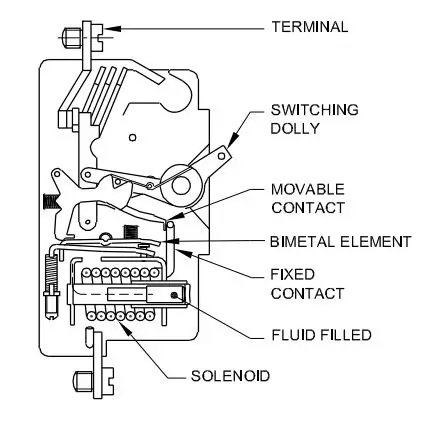

- Terminal for line/load power.

- Bi-metallic strip: Bends with heat (current), separates contacts in response to smaller, longer-term overcurrent, tripping breaker.

- Contacts: Current flows through when closed. Breaks current when separated.

- Arc Chamber: Channels plasma arcing to arc divider.

- Arc divider/extinguisher: Breaks main arc into smaller arcs and extinguishes them.

- Coil/Solenoid: Separates contacts in response to high overcurrents, such as a short circuit.

- Actuator lever: Manually trips or resets breaker.

- Actuator mechanism: Forces contacts together or apart.

But during short circuit condition, the sudden rising of electric current causes electromechanical displacement of plunger associated with tripping coil or solenoid of MCB.

The plunger strikes the trip lever causing an immediate release of latch mechanism consequently open the circuit breaker contacts. This was a simple explanation of a miniature circuit breaker working principle.

Tripping Mechanism in Miniature Circuit Breaker

As explained in the above section, a thermal magnetic MCB has two types of tripping mechanism.

- Thermal Tripping

- Magnetic Tripping

These are explained in the next section.

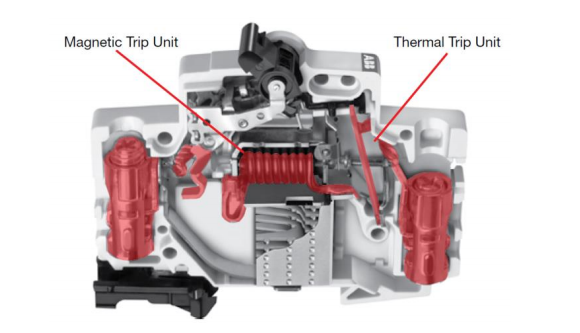

1. Thermal Trip Unit

The thermal trip unit protects against overload currents.

The thermal unit is based on a bimetal element located behind the circuit breaker trip bar and is part of the breaker’s current-carrying path.

When there is an overload, the increased current flow heats the bimetal causing it to bend. As the bimetal bends it pulls the trip bar which opens the breaker’s contacts.

The time required for the bimetal to bend and trip the breaker varies inversely with the current.

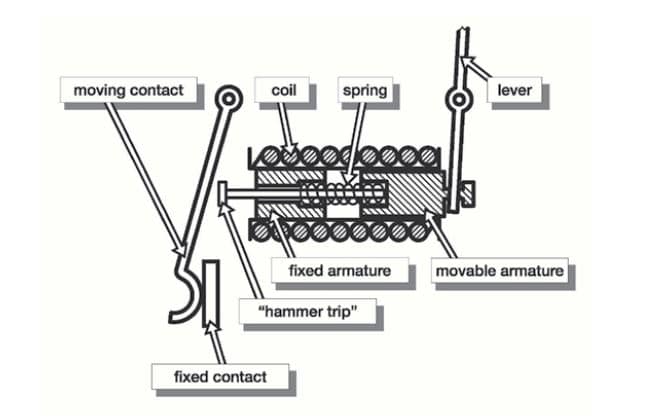

2. Magnetic Trip Unit

The magnetic trip unit protects against a short circuit. The magnetic trip unit is comprised of an electromagnet and an armature.

When there is a short circuit, a high magnitude of current passes through the coils creating a magnetic field that attracts the movable armature towards the fixed armature.

The hammer trip is pushed against the movable contact and the contacts are opened.

Types of MCB

Miniature Circuit Breakers (MCBs) come in various types, each tailored to specific criteria, ensuring efficient protection for electrical systems. Let’s delve into the main categories:

MCB Types based on Tripping Characteristics:

- Type B MCB: Suited for general circuits, trips at moderate overload currents.

- Type C MCB: Ideal for circuits with motors, trips at higher overload currents.

- Type D MCB: Designed for circuits with high inrush currents like lighting.

- Type K MCB: Sensitive to protect electronic circuits.

- Type Z MCB: Offers high selectivity, vital for complex systems.

Types of MCB based on Principles of Operation:

- Thermal Magnetic MCB: Reacts to both thermal overloads and short circuits.

- Magnetic Hydraulic MCB: Blends magnetic precision with hydraulic control for reliability.

- Assisted Bimetallic MCB: Employs bimetallic strips with additional mechanisms for robust protection.

Types of MCB based on Number of Poles:

- Single Pole (SP) MCB: Basic protection for one circuit.

- Double Pole (DP) MCB: Safeguards both live and neutral conductors.

- Triple Pole (TP) MCB: Extends protection to three conductors.

- Three Poles with Neutral (TPN) MCB: Guards three-phase circuits with a neutral connection.

- Four Pole (4p) MCB: Offers comprehensive protection across all phases and neutral.

Understanding these variations in MCB types enables precise selection for diverse electrical applications, ensuring safety and reliability.

| MCB Type | Description |

|---|---|

| Tripping Characteristics | |

| Type B | Suited for general circuits, trips at moderate overload currents. |

| Type C | Ideal for circuits with motors, trips at higher overload currents. |

| Type D | Designed for circuits with high inrush currents like lighting. |

| Type K | Sensitive to protect electronic circuits. |

| Type Z | Offers high selectivity, vital for complex systems. |

| Principles of Operation | |

| Thermal Magnetic | Reacts to both thermal overloads and short circuits. |

| Magnetic Hydraulic | Blends magnetic precision with hydraulic control for reliability. |

| Assisted Bimetallic | Employs bimetallic strips with additional mechanisms for robust protection. |

| Number of Poles | |

| Single Pole (SP) | Basic protection for one circuit. |

| Double Pole (DP) | Safeguards both live and neutral conductors. |

| Triple Pole (TP) | Extends protection to three conductors. |

| Three Poles with Neutral (TPN) | Guards three-phase circuits with a neutral connection. |

| Four Pole (4p) | Offers comprehensive protection across all phases and neutral. |

MCB Types based on Tripping Characteristics

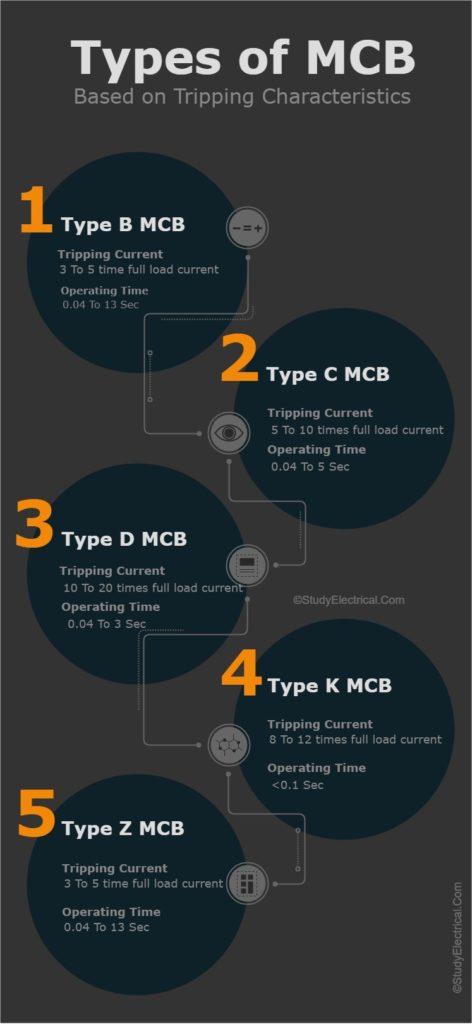

MCBs are classified into different types according to tripping over the range of fault current. The important MCB types are as follows:

- Type B MCB

- Type C MCB

- Type D MCB

- Type K MCB

- Type Z MCB

The tripping current and operating time of each of the above MCB types are given in the table below.

| MCB Type | Tripping Current | Operating Time |

|---|---|---|

| Type B | 3 to 5 times the full load current | 0.04 To 13 Sec |

| Type C | 5 to 10 times the full load current | 0.04 To 5 Sec |

| Type D | 10 to 20 times the full load current | 0.04 To 3 Sec |

| Type K | 8 to 12 times the full load current | <0.1 Sec |

| Type Z | 2 to 3 times the full load current | <0.1 Sec |

1. Type B MCB

This type of MCB trips between 3 and 5 times full load current.

Type B devices are mainly used in residential applications or light commercial applications where connected loads are primarily lighting fixtures, domestic appliances with mainly resistive elements.

Also used for computers and electronic equipment with very low inrush loads (PLC wiring). The surge current levels in such cases are relatively low.

Functions of Type B MCB are protection and control of the circuits against overloads and short-circuits; protection for people and big length cables in TN and IT systems.

Applications: residential, commercial and industrial.

Read more about Type B MCB

2. Type C MCB

This type of MCB trips between 5 and 10 times full load current.

This is used in a commercial or industrial type of applications where there could be chances of higher values of short circuit currents in the circuit.

The connected loads are mainly inductive in nature (e.g. induction motors) or fluorescent lighting. Applications include small transformers, lighting, pilot devices, control circuits, and coils.

Functions of Type C MCB are protection and control of the circuits against overloads and short-circuits; protection for resistive and inductive loads with low inrush current.

Applications: residential, commercial and industrial.

3. Type D MCB:

This type of MCB trips between 10 and 20 times full load current.

These MCBs are used in specialty industrial/commercial uses where current inrush can be very high. Examples include transformers or X-ray machines, large winding motors etc.

D-curve devices are suitable for applications where high levels of inrush current are expected. The high magnetic trip point prevents nuisance tripping in high inductive applications such as motors, transformers, and power supplies.

Functions of Type D MCB are protection and control of the circuits against overloads and short-circuits; protection for circuits which supply loads with high inrush current at the circuit closing ( transformers, breakdown lamps).

Applications: residential, commercial and industrial.

4. Type K MCB

This type of MCB trips between 8 and 12 times full load current. These are Suitable for inductive and motor loads with high inrush currents.

The K and D curve breakers are both designed for motor applications where ampacity rises quickly and momentarily during “start-up.”

Functions of Type K MCB are protection and control of the circuits like motors, transformer, and auxiliary circuits, against overloads and short-circuits.

Advantages of Type K MCB:

No nuisance tripping in the case of functional peak currents up to 8xIn, depending on the series; through its highly sensitive thermostatic bimetal trip, the K-type characteristic offers protection to damageable elements in the overcurrent range; it also provides the best protection to 2 cables and lines.

Applications: Commercial and industrial.

5. Type Z MCB:

This type of MCB trips between 2 to 3 times full load current.

These type of MCBs are highly sensitive to short circuit and are used for the protection of highly sensitive devices such as semiconductor devices.

Functions of Type Z MCB are protection and control of the electronic circuits against weak and long duration overloads and short-circuits.

Applications: Commercial and industrial uses.

All the above types of MCBs provide tripping protection within one-tenth of a second.

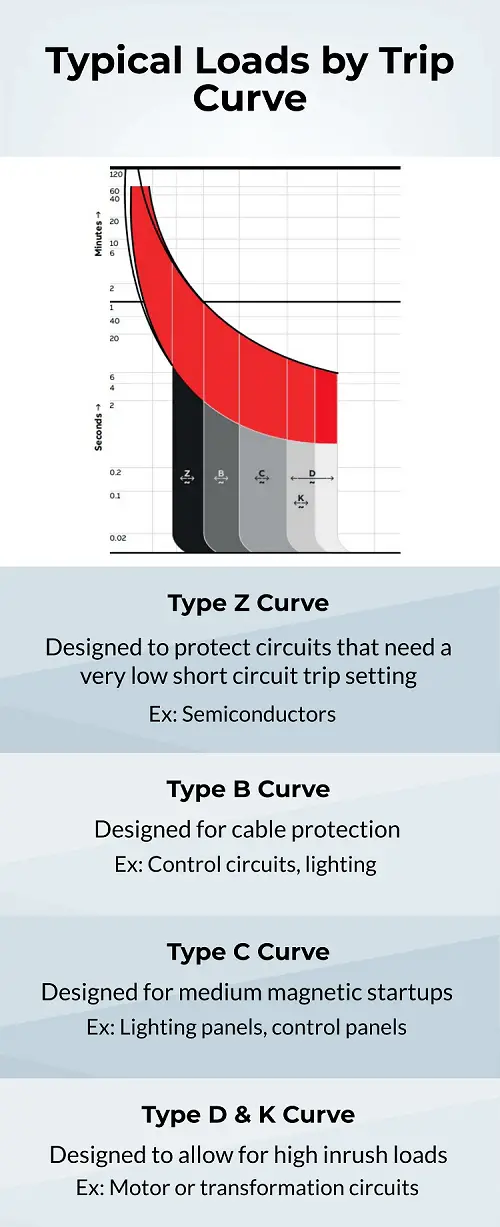

standard) and their typical load types.

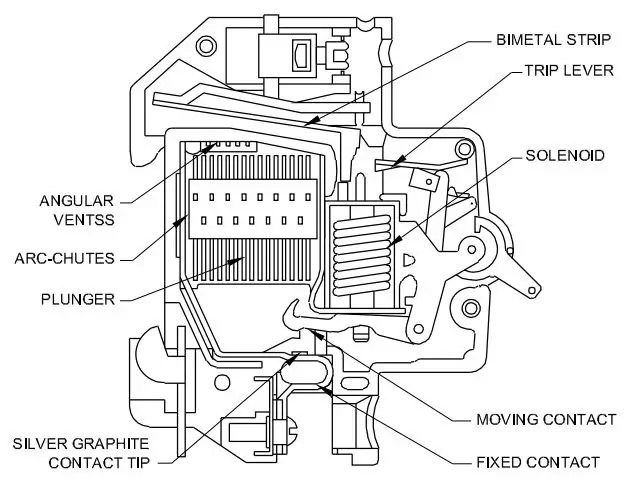

Types of MCB based on Operating Principle

MCBs (Miniature Circuit Breakers) are manufactured with three different principles of operation:

- Thermal magnetic MCB

- Magnetic hydraulic MCB

- Assisted Bimetal Tripping MCB

Thermal Magnetic MCB:

- The switching mechanism is housed in a moulded housing with a high mechanically strong switching dolly.

- It incorporates a bimetallic overload release for protection against overload.

- Electric current passes through two contact tips, one on each moving and fixed contact of silver graphite.

- An arcing chamber with de-ionising arc chutes helps in quick suppression of the arc.

- Thermal magnetic release unit provides protection against overload and short circuit.

- Working:

- The bimetallic strip flexes due to temperature rise caused by increasing current.

- At about 130% overload, the bimetallic strip rotates a trip lever, bringing it into the field of a solenoid.

- The solenoid attracts the armature to trip the breaker at about 700% overload or instantaneous short circuit current.

Magnetic Hydraulic MCB:

- Hydraulic magnetic circuit breaker operates on the principle of a solenoid and hydraulically damped plunger.

- Construction:

- A movable ferrous plunger is held against a non-ferrous tube containing polysiloxane liquid.

- The solenoid is a series coil in the circuit.

- Working:

- As the plunger moves towards a pole piece, the reluctance of the magnetic path decreases, leading to an increasing flux.

- The armature is attracted, causing the mechanism to trip and open the circuit on overload or short circuit.

- Instantaneous tripping occurs on very large currents, typically 7 to 8 times the full load current.

Assisted Bimetal Tripping MCB

In the assisted bimetal form of construction, the time delay characteristic is provided by a thermally operated bimetal element which may be either directly or indirectly heated.

- Time delay characteristic provided by a thermally operated bimetal element.

- Instantaneous tripping in short circuit condition achieved by arranging a powerful magnetic pull to deflect the bimetal.

- Utilizes the magnetic field produced when a current flows through the conductor to deflect the bimetal sufficiently to trip the breaker.

Types of MCB based on Number of Poles

Another practical way of distinguishing MCBs is by way of the number of poles supported by the circuit breaker. Based on that, the following types exist:

1. Single Pole (SP) MCB

A single-pole MCB provides switching and protection only for one single phase of a circuit.

2. Double Pole (DP) MCB

A two Pole MCB provides switching and protection both for a phase and the neutral.

3. Triple Pole (TP) MCB

A triple/three phase miniature circuit breaker provides switching and protection only to three phases of the circuit and not to the neutral.

4. Three Pole with Neutral [TPN (3P+N) MCB]

A TPN MCB has switching and protection to all three phases of the circuit and additionally Neutral is also part of the MCB as a separate pole.

However, Neutral pole is without any protection and can only be switched.

5. Four Pole (4P) MCB

A 4 pole MCB is similar to TPN but additionally, it also has a protective release for the neutral pole.

This MCB should be used in cases where there is a possibility of high neutral current flow through the circuit as in cases of an unbalanced circuit.

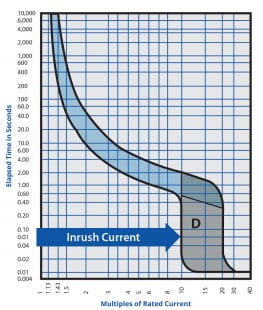

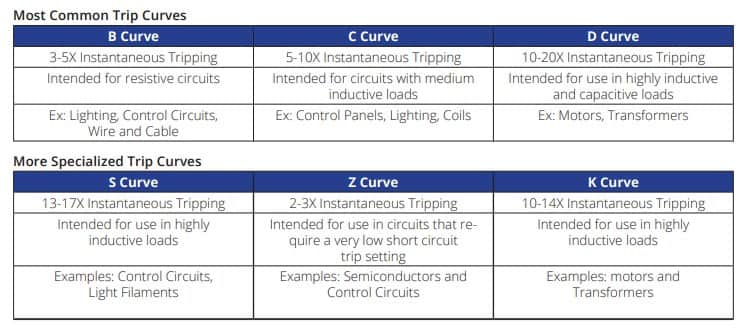

MCB Characteristic/Trip Curves (Type B,C & D)

In this section, you will learn the characteristics or trip curves of different MCB types. Understanding the trip curves is very important to help you in MCB selection.

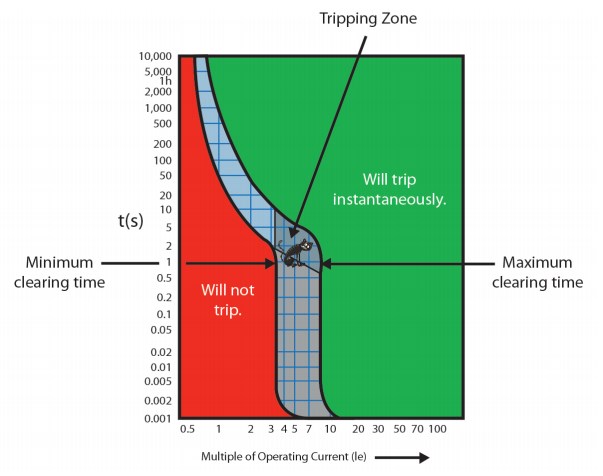

What are Trip Curves?

The Characteristic Curve / Trip Curve is the graphical representation of the expected behavior of the circuit protection device.

Circuit protection devices come in many forms, including fuses, miniature circuit breakers, molded case circuit breakers, supplementary protectors, motor protection circuit breakers, overload relays, electronic fuses, and air circuit breakers.

Trip Curve is normally plotted between the release current and tripping time (Time – Current Curve). They are provided by the manufacturers of circuit protection devices to assist users with selecting devices that provide proper equipment protection and performance while avoiding nuisance tripping.

The circuit breaker’s trip curves consist of two parts:

- Tripping of overload protection (thermal tripping device): The higher the current, the shorter the tripping time

- Tripping of short-circuit protection (magnetic tripping device): If the current exceeds the threshold of this protection device, the breaking time is less than 10 milliseconds.

The first sloping region of the curve is a graphical representation of the tripping characteristics of the thermal trip unit. This portion of the curve is sloped due to the nature of the thermal trip unit.

The second region is the response time of the magnetic trip which differentiates each characteristic and for which an identifying letter (Type B, C, D, K, Z) is assigned.

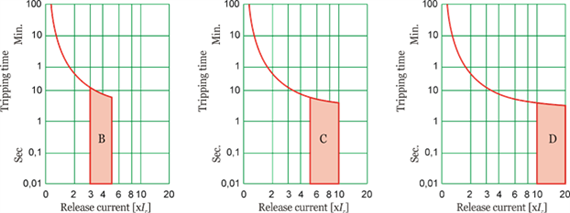

The classification of Type B, C or D is based on fault current rating at which magnetic operation occurs to provide short-time protection (typically less than 100ms) against short circuits.

The most important MCB characteristics are

- Type B characteristic curves.

- Type C characteristic curves.

- Type D characteristic curves.

There are some specialized trip curves such as

- Type S Curve

- Type Z Curve

- Type K Curve

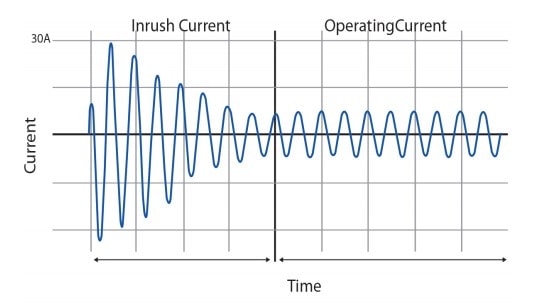

Why do we Need Different Trip Curves?

At this point, one question comes into your mind “What is the need for different types of Trip Curves” or “Why do we need different Trip Curves”.

The role of a circuit breaker is to trip quickly enough to avoid equipment or wiring failure, but not so fast as to give false, or nuisance trips.

It is important that equipment having high inrush currents should not cause the circuit breaker to trip unnecessarily, and yet the device should trip in the event of a short-circuit current that could damage the circuit cables.

We need different trip curves in order to balance the right amount of overcurrent protection against optimal machine operation. Choosing a circuit breaker with a trip curve that trips too soon can result in nuisance tripping. Choosing a circuit breaker that trips too late can result in catastrophic damage to machine and cables.

Now we will look into each of the three important trip curves mentioned above.

1. Type B Curve

Type B devices are generally suitable for domestic applications. They may also be used in light commercial applications where switching surges are low or non-existent.

They are designed to trip at fault currents of 3-5 times rated current. For example, a 10A device will trip at 30-50A.

2. Type C Curve

Type C devices are the normal choice for commercial and industrial applications where fluorescent lighting, motors etc. are in use.

These devices are designed to trip at 5-10 times rated current (50-100A for a 10A device).

3. Type D Curve

The Type D devices have more limited applications, normally in industrial use where high inrush currents may be expected.

Examples include large battery charging systems, winding motors, transformers, X-ray machines and some types of discharge lighting. Type D devices are designed to trip at 10-20 times (100-200A for a 10A device).

Normal cable ratings relate to continuous service under specified installation conditions. Cables will, of course, carry higher currents for a short time without suffering permanent damage.

Type B and C circuit breakers can generally be selected to achieve tripping times that will protect the circuit conductors against normal surge currents in accordance with BS 7671. This is more difficult to achieve with Type D devices, which may require a lower earth loop impedance (Zs) to achieve tile operating times required by Regulation 413-02-08.

Sources of Surge currents

Surge currents in domestic installations are generally low so that a Type B device is adequate.

For example, inrush currents associated with one or two fluorescent fittings or the compressor motor in a refrigerator/freezer are unlikely to cause unwanted tripping. Fluorescent and other discharge lamps produce surge currents and while one or two fluorescent lamps are unlikely to cause a problem, the block switching of a number of fluorescent lamps.

In a shop, office or factory can produce substantial inrush currents. For this reason, Type C devices are recommended for these applications.

The magnitude of the surge current will depend on the lamp rating, starting system, and type of control gear used in the luminaires.

Reputable Miniature Circuit Breaker manufacturers produce tables listing the number of fittings of a particular make and type that can be used with their devices.

Overcoming Unwanted Tripping of MCB

Sometimes the failure of tungsten filament lamps can trip Type B miniature circuit breakers in domestic and retail environments.

This is caused by high arcing currents occurring at the time of failure and is generally associated with inferior quality lamps. If possible the user should be encouraged to use better quality lamps. If the problem persists then one of the measurements listed below should be considered.

A Type C device may be substituted for a Type B device where unwanted tripping persists, especially in commercial applications.

Alternatively, it may be possible to use a higher rating Type B MCB, say 10A rather than 6A.

Whichever solution is adopted, the installation must be in accordance with BS 7671.

A change from Type C to Type D devices should only be taken after careful consideration of the installation conditions, in particular, the operating times required by regulation.

Other Considerations

The importance of selecting circuit-breakers from reputable manufacturers cannot be overemphasized. Some imported products, claiming to have a 6kA short-circuit capacity, had failed dramatically under test.

In contrast, the test procedures followed in British ASCTA (Association of Short Circuit Testing Authorities) laboratories are among the most suitable in the world.

Type B devices should only be used in domestic situations where high inrush currents are unlikely and Type C devices should be used in all other situations.

Selection of Right MCB

The decision to use Type B, C or D miniature circuit breakers for final circuit protection in residential, commercial, industrial or public buildings can be based on a few simple rules.

However, an understanding of the differences between these types of devices can help the installer overcome problems of unwanted tripping or make a suitable selection where lines of demarcation are less clearly defined.

It should be stressed that the primary purpose of circuit protection devices such as miniature circuit breakers and fuses is to protect the cable downstream of the device.

The essential distinction between Type B, C or D devices is based on their ability to handle surge currents without tripping. These are, typically, inrush currents associated with fluorescent and other forms of discharge lighting, induction motors, battery charging equipment, etc.

- Type B, C, and D are used for overcurrent protection of cables in accordance with IEC/EN 60898-1

- Type K for the protecting motors and transformers and simultaneous overcurrent protection of cables with overload tripping based on IEC/EN 60947-2

- Type Z for control circuits with high impedances, voltage converter circuits, and semi cable protection and simultaneous overcurrent protection of cables with overload tripping based on IEC/EN 60947-2.

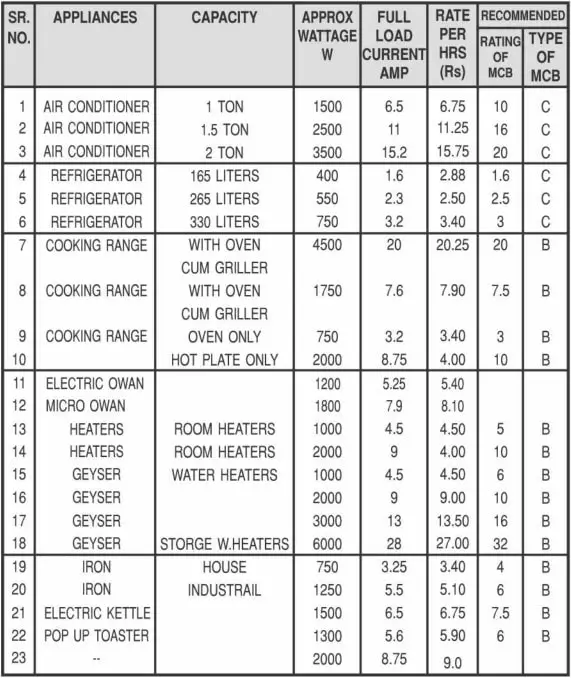

How To Select Rating Of MCB at a Particular Circuit

If the proper rating is not selected on a particular circuit, there will be no proper functions of MCB at overload. Therefore it is very important to select the right rating of MCB which can be easily calculated as under.

Example

Let’s imagine you have 4 Fans, One TV, 4 Tubes, One V.C.D., One Refrigerator & one 1.5 Ton Air Conditioner on a particular circuit.

The current in that circuit will be (4 x 0.40) + (0.55) + (4×0.20) + (0.22) + (1.6) + (11) = 16 AMP.

Therefore, the suitable rating of MCB will be 20 AMP B Series.

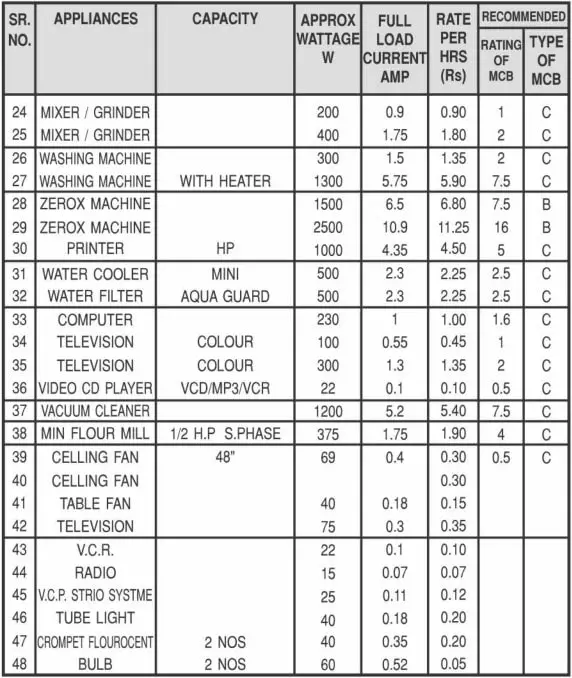

For ready reference current of some important appliance is given below to calculating the preferred rating of MCB.

Calculating Power consumption : 1 Unit = Rs. 4.50 = 1000 watt/hours = 1 Kw/hours.

MCB Selection Table

The MCB selection table helps you to choose the right MCB for protecting your circuit.

| SR. NO. | APPLIANCES | CAPACITY | APPROX WATTAGE (W) | LOAD CURRENT (A) | RECOMMENDED RATING OF MCB | TYPE OF MCB |

|---|---|---|---|---|---|---|

| 1 | AIR CONDITIONER | 1 TON | 1500 | 6.5 | 10 | C |

| 2 | AIR CONDITIONER | 1.5 TON | 2500 | 11 | 16 | C |

| 3 | AIR CONDITIONER | 2 TON | 3500 | 15.2 | 20 | C |

| 4 | REFRIGERATOR | 165 LITERS | 400 | 1.6 | 1.6 | C |

| 5 | REFRIGERATOR | 265 LITERS | 550 | 2.3 | 2.5 | C |

| 6 | REFRIGERATOR | 330 LITERS | 750 | 3.2 | 3 | C |

| 7 | COOKING RANGE WITH OVEN CUM GRILLER | 4500 | 20 | 20 | B | |

| 8 | COOKING RANGE WITH OVEN CUM GRILLER | 1750 | 7.6 | 7.5 | B | |

| 9 | COOKING RANGE OVEN ONLY | 750 | 3.2 | 3 | B | |

| 10 | HOT PLATE ONLY | 2000 | 8.75 | 10 | B | |

| 11 | ELECTRIC OVEN | 1200 | 5.25 | |||

| 12 | MICROWAVE OVEN | 1800 | 7.9 | |||

| 13 | HEATERS | 1000 | 4.5 | 5 | B | |

| 14 | HEATERS ROOM HEATERS | 2000 | 9 | 10 | B | |

| 15 | GEYSER WATER HEATERS | 1000 | 4.5 | 6 | B | |

| 16 | GEYSER | 2000 | 9 | 10 | B | |

| 17 | GEYSER | 3000 | 13 | 16 | B | |

| 18 | GEYSER STORGE W.HEATERS | 6000 | 28 | 32 | B | |

| 19 | IRON HOUSE | 750 | 3.25 | 4 | B | |

| 20 | IRON INDUSTRAIL | 1250 | 5.5 | 6 | B | |

| 21 | ELECTRIC KETTLE | 1500 | 6.5 | 7.5 | B | |

| 22 | POP UP TOASTER | 1300 | 5.6 | 6 | B | |

| 23 | POP UP TOASTER | 2000 | 8.75 | |||

| 24 | MIXER / GRINDER | 200 | 0.9 | 1 | C | |

| 25 | MIXER / GRINDER | 400 | 1.75 | 2 | C | |

| 26 | WASHING MACHINE | 300 | 1.5 | 2 | C | |

| 27 | WASHING MACHINE WITH HEATER | 1300 | 5.75 | 7.5 | C | |

| 28 | ZEROX MACHINE | 1500 | 6.5 | 7.5 | B | |

| 29 | ZEROX MACHINE | 2500 | 10.9 | 16 | B | |

| 30 | PRINTER | HP | 1000 | 4.35 | 5 | C |

| 31 | WATER COOLER | MINI | 500 | 2.3 | 2.5 | C |

| 32 | WATER FILTER | AQUA GUARD | 500 | 2.3 | 2.5 | C |

| 33 | COMPUTER | 230 | 1 | 1.6 | C | |

| 34 | TELEVISION | COLOUR | 100 | 0.55 | 1 | C |

| 35 | TELEVISION | COLOUR | 300 | 1.3 | 2 | C |

| 36 | VIDEO CD PLAYER | VCD/MP3/VCR | 22 | 0.1 | 0.5 | C |

| 37 | VACUUM CLEANER | 1200 | 5.2 | 7.5 | C | |

| 38 | MIN FLOUR MILL | 1/2 H.P S.PHASE | 375 | 1.75 | 4 | C |

| 39 | CELLING FAN | 48″ | 69 | 0.4 | 0.5 | C |

| 40 | CELLING FAN | 0 | 0.30 | |||

| 41 | TABLE FAN | 40 | 0.18 | |||

| 42 | TELEVISION | 75 | 0.3 | |||

| 43 | V.C.R. | 22 | 0.1 | |||

| 44 | RADIO | 15 | 0.07 | |||

| 45 | V.C.P. STRIO SYSTME | 25 | 0.11 | |||

| 46 | TUBE LIGHT | 40 | 0.18 | |||

| 47 | CROMPET FLOUROCENT | 2 NOS | 40 | 0.35 | ||

| 48 | BULB | 2 NOS | 60 | 0.52 |

Comments are closed.