A process of connecting various accessories for distribution of electrical energy from supplier’s meter board to home appliances such as lamps, fans and other domestic appliances is known as Electrical Wiring.

The wiring system selected will depend to a large extent on the types of service required.

The types of internal wiring systems usually employed are:

- Cleat wiring

- Casing and capping wiring

- Batten wiring

- CTS or TRS or PVC sheath wiring

- Lead sheathed or metal sheathed wiring

- Conduit wiring

- Surface or open Conduit type

- Concealed or underground type Conduit

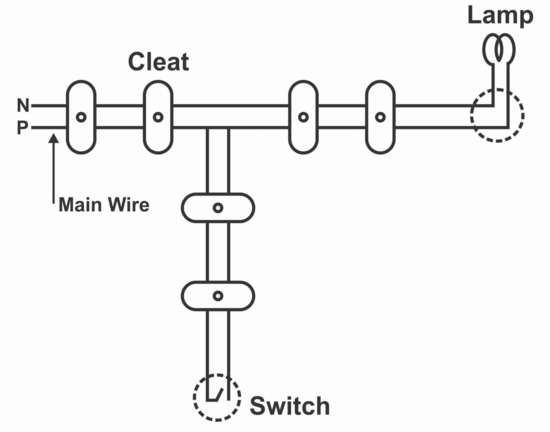

Cleat Wiring

Cleat wiring is the cheapest system of wiring. In this system the cables used are either VIR or PVC type. The cables are held by porcelain cleats about 6 mm above the walls or ceiling.

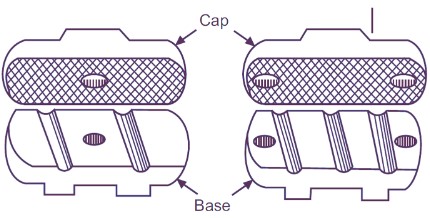

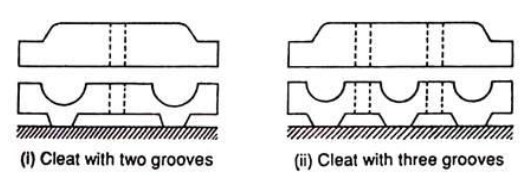

The cleats are made in two halves, one base and the other cap. The base is grooved to accommodate the cables and the cap is put over it and whole of it is then screwed on wooden plugs (gutties) previously cemented into the wall or ceiling. Thus the cables are firmly griped between the two halves of the cleats and secured to the supporting wall or ceiling.

The cleats used are of different sizes and different types in order to accommodate cables of various sizes and different numbers of cables respectively. The cleats are of three types—one groove, two grooves and three grooves to accommodate one, two, and three cables respectively.

Application:

- Cleat wiring is very suitable for temporary installations in dry places.

- This is also acceptable where appearance is not so important and cheapness is the main consideration.

- This system is not suitable for use in domestic premises.

Advantages

- It is the cheapest system.

- Installation and dismantling is easy.

- Less skilled persons are required.

- Inspection is easy.

- Alterations and additions are easy.

Disadvantages

- It is purely temporary wiring system.

- Appearance is not good.

- Cables are exposed to atmosphere and there is a possibility of mechanical injury.

- This system should not be used in damp places other wise insulation gets damaged.

Wooden Casing and Capping Wiring

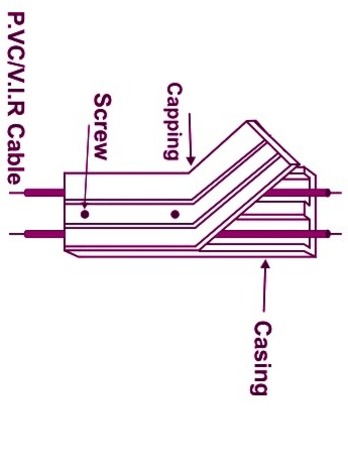

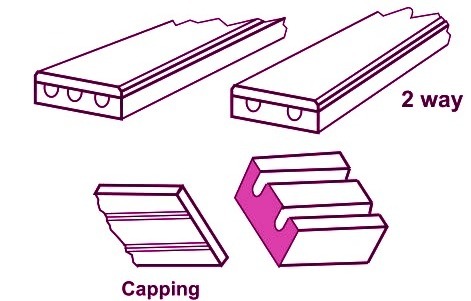

The cable used in this type of wiring is either VIR or PVC or any other approved insulated cables.

The cables are carried through the wooden casing enclosures. The casing consists of V-shaped grooves (usually two to hold the cables of opposite polarity in different groves) and is covered at the top by means of rectangular strip of wood, known as capping, of same width as that of casing. The capping is screwed to the casing by means of wooden screws fixed at every 15 cm on the centre fillet.

To protect the casing against white ants first class seasoned teak wood, varnished by shellac varnish is employed. Two or three cables of same polarity (either all phases or all neutrals) may be run in one groove and in no case the cables of opposite polarity should be run in the same groove. The casing is usually placed 3.2 mm apart from the wall or ceiling by means of porcelain distance pieces of thickness not less than 6.5 mm in order to keep the casing dry at the back.

Advantages

- It provides good insulation as conductors are apart.

- It provides good mechanical strength.

- Easy to inspect by opening the capping.

Disadvantages

- It is costly system now – a – days because it needs seasoned, knot free wood.

- There is every risk of fire.

- The labor cost is more because it requires skilled carpenters.

- This system can not be used in damp places.

CTS or TRS Wiring

In this type of wiring the cables used may be single core, twin core or three core TRS cables with a circular oval shape. Usually single core cables are preferred.

TRS cables are sufficiently chemical proof, water proof, steam proof but are slightly affected by lubricating oils. TRS aloes are run on well-seasoned, perfectly straight and well varnished (on all four sides) teak wood batten of thickness 10 mm at least. The width of the batten depends upon the number and size of cables to be carried by it.

The wooden battens are secured to the walls or ceiling by flat head wood screws to wood or other approved plugs at an interval not exceeding 75 cm. The cables are held on the wooden batten by means of tinned brass link clips already fixed on the batten with brass pins and spaced at an interval of 10 cm in case of horizontal runs and 15 cm in case of vertical runs. The wiring after erection is neatly painted with two coats of oil-less non cracking paint as specified in IS 732 and so on.

Application:

The TRS wiring is suitable for low voltage installations and is extensively used for lighting purposes everywhere i.e. in domestic, commercial or industrial buildings except workshop where it is liable to mechanical injury. This type of wiring is suitable in situations where acids and alkalies are likely to be present.

Advantages

- It’s appearance is good, if carried properly.

- It’s life is sufficiently long.

- It can withstand the action of most chemicals such as acids and alkalies.

- It’s installation is easy and quick compared to casingcapping.

- It is cheap compared to casing – capping, metal conduit and lead sheathed wiring.

Disadvantages

- This system of wiring is not recommended in situations exposed to sun and rain, unless preventive steps are taken.

- It can not be used in damp places.

- Good work man ship is required to make a sound job.

- Only suitable below then 250V

Conduit Wiring

In this system of wiring steel tubes, known as conduits, are installed on the surface of walls by means of saddles or pipe hooks or buried under plaster and VIR or PVC cables are drawn into afterwards by means of a GI wire of size of about 18 SWG.

In damp situations the conduits can be spaced from the walls by means of small wooden blocks fixed below the pipes at regular intervals. In order to facilitate drawing of wires numbers of inspection fittings are provided along its length. The conduits should be electrically and mechanically continuous and connected to earth at some suitable point.

The conduits used for this purpose are of two types namely

- Light gauge (or split type) conduit

- Heavy gauge (or screwed type) conduit.

Light gauge or split conduit with a seam along its length is used for cheap work. It is not water tight or even damp proof and is not permitted on medium voltage (i.e. on voltages higher than 250V).

Screwed conduit (solid drawn or with welded seam) is used for all medium voltage (250 V or 600 V) circuits and in places where good mechanical protection and absolute protection from moisture is desired.

In general the finish of the conduit is black stove-enamelled, there being a smooth coating of enamel both on the inside and outside surface of the tube. Galvanized conduit is also employed, especially in damp situation when the conduit is on the surface but under ordinary conditions buried in walls it offers little, if any, advantage over good enamelled conduits.

Comparison Between Various Systems of Wiring:

| Particulars | Cleat Wiring | Wood Casing-Capping Wiring | TRS Wiring | Lead Sheathed Wiring | Conduit Wiring |

| Material Required | Cleat, VIR or PVC cables, wooden gutters, screws, block, etc | Teak wood, TRS or PVC cables, screws, block, etc | Teak wood batten, TRS or PVC cables, screws, block, nails, clips, etc | Teak wood batten, Lead sheath cables, screws, block, nails, clips, etc | Conduit pipe, VIR or PVC cable, saddles, hook, tees, IC box, etc |

| Cost | Low | medium | Medium | Costly | very costly |

| Durability | very short | fairly long | Long | Long | very long |

| Type of labor required | semi-skilled | highly skilled | medium-skilled | medium-skilled | highly skilled |

| Appearance | not good | Fair | Good | Fair | very good |

| Mechanical Protection | none | fairly good | Good | medium-skilled | very good |

| Voltage | up to 250 volt | up to 250 volt | up to 250 volt | up to 250 volt | up to 660 volt |

| Application | For temporary purpose e.g., camp, marriage, etc | For residential and commercial | For residential and commercial | For service mains | For residential and commercial, workshop, godown, etc |