Thermal Magnetic circuit breakers are indispensable components in electrical systems, offering crucial protection against overload and short circuits. In this comprehensive guide, we delve into the intricacies of their construction and functioning, shedding light on their importance and applications in various industries.

What is a Thermal Magnetic Circuit Breaker?

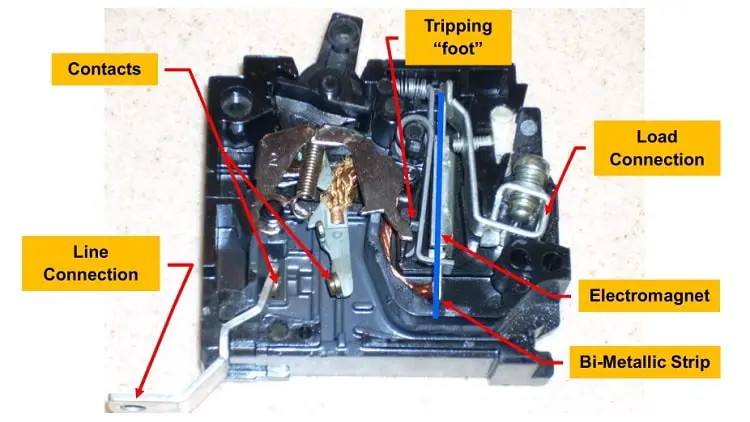

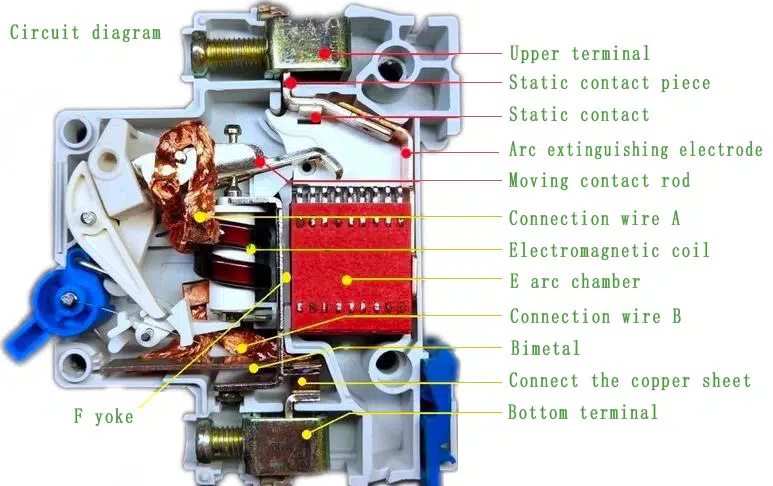

A thermal magnetic circuit breaker is a switchgear device designed to automatically interrupt electrical flow when it detects excessive current or heat buildup in a circuit. Comprising two main components – a magnetic coil and a bimetallic strip – these breakers operate on the principle of electromagnetism and thermal expansion.

The other type of MCB based on operating principle other than thermal magnetic circuit breaker is Hydraulic Magnetic Circuit Breaker.

Construction of Magnetic Thermal Circuit Breakers:

Magnetic Coil:

- The magnetic coil, also known as the solenoid coil, forms the core component of the breaker’s magnetic trip mechanism.

- Constructed from insulated copper wire wound around a ferromagnetic core, the coil generates a magnetic field when current passes through it.

- The strength of the magnetic field is directly proportional to the current flowing through the circuit.

Bimetallic Strip:

- The bimetallic strip is a crucial element responsible for the thermal trip mechanism in the circuit breaker.

- Fabricated by bonding two different metals with different coefficients of thermal expansion, typically steel and copper or brass, the strip deflects when exposed to heat.

- As current flows through the circuit, the strip heats up, causing it to bend and ultimately trigger the tripping mechanism.

Working Principle:

Normal Operating Conditions:

- Under normal operating conditions, the current flowing through the circuit is within the permissible range, and the bimetallic strip remains in its original position.

- The magnetic field generated by the coil is not strong enough to overcome the magnetic force exerted by the calibrated spring, keeping the contacts closed.

Overload or Short Circuit:

- When an overload or short circuit occurs, the current surpasses the rated capacity of the circuit, leading to excessive heating.

- The heat causes the bimetallic strip to bend, exerting pressure on the trip bar and releasing the latch mechanism.

- Simultaneously, the increased current strengthens the magnetic field generated by the coil, overpowering the spring force and pulling the contacts apart, thus interrupting the electrical flow.

Arc quenching

In the design of thermal-magnetic circuit breakers, arc quenching is a crucial consideration.

- Understanding Electric Arcs:

- When a circuit breaker interrupts an overcurrent, the gap between its contacts leads to heating of air, forming an electric arc.

- Heated air and gases become conductive, with conductivity increasing as temperature rises.

- Risk of Uncontrolled Arcs:

- Uncontrolled arcs can cause rapid air expansion, potentially damaging the circuit breaker.

- Importance of Arc Quenching:

- Besides separating contacts swiftly, circuit breakers must extinguish the arc promptly.

- Factors for Arc Quenching:

- Speed: Rapid contact separation reduces arc formation and sustenance time.

- Distance: Increasing contact gap forces the arc to stretch, requiring higher voltage to maintain current flow.

- Cooling: Directing the arc against a cold material facilitates heat dissipation.

- Dielectric Strength: Using mediums like sulfur hexafluoride (SF6) with higher dielectric strength aids arc quenching.

- Arc Quenching Mechanisms:

- Arc Chutes or Dividers:

- The arc is directed into arc chutes/dividers upon contact separation.

- Fragmentation of the arc reduces its energy level, leading to dissipation.

- Arc Chutes or Dividers:

Applications

Thermal magnetic circuit breakers find widespread applications across various industries, including:

- Residential and commercial electrical panels

- Industrial machinery and equipment

- Automotive systems

- Marine and aerospace applications

Conclusion:

In summary, magnetic thermal miniature circuit breakers play a pivotal role in ensuring the safety and reliability of electrical systems by swiftly disconnecting power during abnormal conditions. Understanding their construction, working principle, and applications is essential for engineers, electricians, and anyone involved in the design and maintenance of electrical installations. Embracing these insights empowers stakeholders to make informed decisions and uphold the integrity of electrical infrastructure.