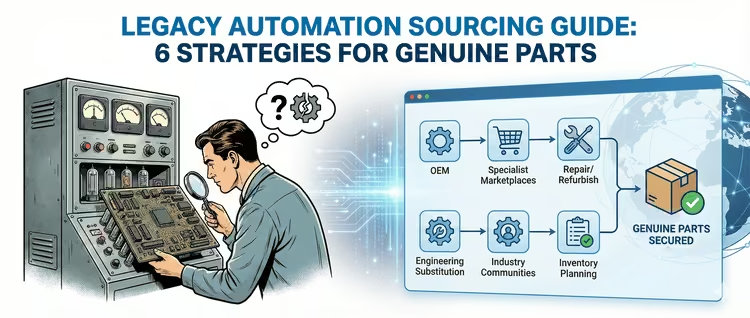

Maintaining legacy automation systems presents a significant challenge: these machines often rely on specific, often discontinued integrated circuits (ICs), control modules, or proprietary connectors. When these components fail, the lack of readily available spares creates an immediate risk to production uptime and operational stability. Engineers must navigate a fragmented global supply chain to find genuine parts while actively mitigating the risk of counterfeits.

This guide presents six practical, low-risk strategies for locating and securing genuine, hard-to-find components. After reading this, you will be able to prioritize sourcing channels, validate the authenticity of parts, and build a reliable procurement plan to secure your spare parts inventory.

Strategy 1: Start with OEM & Authorized Distributors

Why OEMs First

The Original Equipment Manufacturer (OEM) remains the most reliable primary source for authentic components and formal documentation. Even if the part is discontinued, the OEM can provide formal obsolescence documentation, recommend certified cross-reference part numbers, or direct you to an authorized remanufacturing program. Starting here establishes a baseline for authenticity and provides critical lifecycle data.

Action Checklist

- Contact the OEM’s dedicated support line and request formal Last-Time-Buy (LTB) notices for the specific part number.

- Ask for recommended supersedes or Engineering Change Notices (ECNs) that detail viable alternatives.

- Request part traceability paperwork, including lot numbers and Certificates of Conformity (COA), especially for critical safety components.

Strategy 2: Use Specialist Obsolete Parts Marketplaces

How Specialist Marketplaces Help

When OEM stock is depleted, specialist marketplaces dedicated to legacy and obsolete stock become essential. These platforms aggregate global inventories from independent brokers, salvage houses, and vetted third-party distributors. They accelerate searches for scarce Stock Keeping Units (SKUs) and provide a window into the global availability of parts that have moved through the official supply chain.

Practical Tips

- Search multiple listings and carefully compare the quality of lot/packaging photos, looking for consistent branding and condition.

- Prefer sellers who offer serialized inventory and verifiable quality control certificates.

- When checking specialist listings, include targeted queries such as “Iainventory obsolete parts” to find suppliers that specialize in end-of-life industrial components.

Strategy 3: Leverage Repair & Refurbishment Channels

What This Channel Offers

Professional refurbishers and repair shops often maintain extensive libraries of functional modules and boards harvested from decommissioned equipment. This channel is excellent for complex electronic modules, such as specialized power supplies or calibrated analog cards, which benefit from component-level testing and repair. They can often provide a fully tested, functional replacement much faster than global sourcing.

Steps to Follow

- Identify reputable repair houses with proven experience and references in your specific industry (e.g., process control or heavy manufacturing).

- Request specific functional test results and calibration certificates for the swapped or repaired module.

- Always negotiate a clear returns policy or a limited operational warranty for refurbished parts to reduce integration risk.

Strategy 4: Cross-reference and Engineering Substitution

When Substitution is Viable

For many common discrete components—like passive components, basic logic gates, or certain power transistors—a controlled substitution can extend the system’s life with lower risk than chasing old stock. An experienced engineer can identify drop-in or near-drop-in supersedes that meet all necessary electrical and mechanical constraints defined in the original Bill of Materials (BOM). This strategy requires rigorous validation but offers a long-term fix.

Substitution Checklist

- Match pinout, package dimensions, timing characteristics, and all electrical tolerances (e.g., Vcc, logic thresholds).

- Validate the thermal dissipation and de-rating specifications to ensure the new component performs reliably at the equipment’s operating temperature.

- Update internal schematics and the system’s BOM with cross-reference notes, citing the new supplier and data sheets for future maintenance.

Strategy 5: Tap Industry Forums, User Groups, and Equipment Communities

Why Community Sourcing Works

Niche industry forums and dedicated user groups (often centered around specific PLC brands or machinery) frequently contain invaluable unindexed information. Field engineers and technicians often share knowledge about remaining surplus stock, local dealer leads, or personal inventories. These networks can also be critical for surfacing practical, field-verified tips for part verification or module refurbishment.

How to Approach

- Post clear part numbers, high-resolution photos, and the specific application context; explicitly ask only for tested, verifiable sources.

- Vet responses by checking the contributor’s history and corroborating any supplier leads through formal business checks.

- Follow up privately to negotiate the purchase or trade, maintaining professionalism throughout the transaction.

Strategy 6: Plan for Inventory & Lifecycle Mitigation

Proactive Inventory Strategies

The most effective sourcing strategy is proactive inventory management. Establishing a strategic spare parts stock, utilizing Last-Time-Buy (LTB) opportunities, and creating consignment agreements with local vendors reduce reliance on reactive, high-stress searches. When procuring new equipment, include lifecycle clauses that mandate notification timelines for component obsolescence.

Policy Checklist

- Define minimum spares levels per critical production asset based on failure criticality.

- Set reorder triggers based on MTTR (Mean Time To Repair) and MTBF (Mean Time Between Failures) metrics, not just stock count.

- Integrate obsolescence monitoring into the routine workflow of your CMMS (Computerized Maintenance Management System).

Verify & Test Before Deployment

Essential Verification Steps

Always assume third-party sourced parts require verification. Begin with a thorough visual inspection—check for mismatched markings, poor printing, or incorrect packaging against OEM photos. Next, perform basic continuity tests and run a functional bench test under a representative electrical load and operating temperature. For safety-critical parts, non-destructive testing like X-ray Fluorescence (XRF) can confirm material composition. Document the part’s serials, lot numbers, and test results for future traceability in the CMMS.

Procurement & Acceptance Checklist

- Authenticity: Confirm lot codes and request Certificates of Analysis (COA) or test reports.

- Warranty: Require a limited operational warranty (e.g., 30 days functional) from the supplier.

- Bench Test: Validate electrical and mechanical fit on a test bench; run at least a 24-hour burn-in for critical modules before installation.

- Record Keeping: Record procurement metadata (date, supplier, batch) in the CMMS against the asset.

FAQ

Q: How do I tell if a part is counterfeit?

A: Check packaging and marking against high-resolution OEM photos. Request COA from the vendor. Mismatched fonts, poor solderability, or unexpected packaging seals are major red flags.

Q: Is it risky to mix refurbished with new parts?

A: Not if refurbished parts are sourced from reputable providers with test certificates and a warranty. Segregate them in inventory and track their specific failure rates separately to inform future procurement decisions.

Q: How many spares should I stock for legacy gear?

A: Base the quantity on failure criticality and lead time. For critical PLC modules, stock 1–2 hot spares per production line or ensure a documented, rapid-replacement agreement is in place.

Q: What if no source has genuine parts?

A: Consider four options: controlled engineering substitution (Strategy 4), commissioning a reverse-engineering project with a trusted integrator, using a qualified repair house, or, ultimately, upgrading the obsolete subsystem if the total cost justifies it.

Conclusion

Sourcing scarce legacy components requires a comprehensive strategy that combines official OEM outreach, targeted use of specialist marketplaces, utilization of repair channels, and proactive inventory planning. Use these checklists to reduce critical downtime and minimize procurement risk in your legacy auto