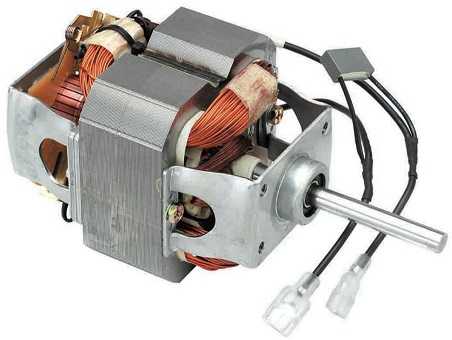

A universal motor is one of the single-phase motors that can be operated on either direct current or single-phase alternating current at approximately the same speed.

This motor is most popular in the fractional-horsepower size and is used in household appliances such as vacuum cleaners, food mixers, drills, sewing machines, and power handsaws.

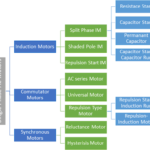

There are several types of universal motors in use today.

- The most popular type is similar to the small two-pole series motor with two concentrated field poles.

- Another type of universal motor has a field winding distributed in slots, much the same as the split-phase motor.

These motors are generally made in sizes varying from 1/200 to 1/3 HP but are obtainable in much larger sizes for special applications.

Construction of Universal Motors

- frame

- field core

- armature

- endplates.

The frame is a rolled steel, aluminum, or cast-iron shell similar to that in Figure 2 and large enough to hold the field core laminations comfortably.

Very often the frame is constructed to form an integral part of the machine it supports.

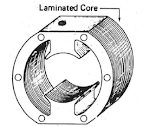

The field core is constructed of laminations that are tightly pressed together and held by rivets or bolts. As shown in Figure, the laminations are designed to contain both field poles of a two-pole motor.

The armature is similar to that of the small DC motor. It consists essentially of a laminated core having either straight slots or skewed slots and a commutator to which the leads of the armature winding are connected.

Both the core and commutator are pressed on the shaft.

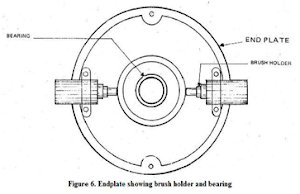

As in other motors, the endplates are located on the ends of the frame and held in place by screws.

Many universal motors contain an end plate that is cast as part of the frame. Only one plate can be removed from this type of motor. Brush holders are usually bolted to the front endplate.