There are several tests that are conducted for testing a dc machine (generator or motor) to judge its performance. The most important performance tests to be conducted on the dc machine are:

- The magnetization or open-circuit test.

- The load characteristic.

- The determination of the efficiency curve.

- The temperature rise test.

This article mainly deals with the determination of the efficiency curve. The efficiency of a dc machine depends upon its losses. The smaller the losses, the greater is the efficiency of the machine and vice-versa.

The consideration of losses in a dc machine is important for two principal reasons.

- First, losses determine the efficiency of the machine and appreciably influence its operating cost.

- Secondly, losses determine the heating of the machine and hence the power output that may be obtained without undue deterioration of the insulation.

In this article, we shall focus our attention on the various methods for the determination of the efficiency of a DC machine.

Efficiency of a DC Machine

The determination of the efficiency of DC machine is important for the testing of DC machines. The power that a dc machine receives is called the input and the power it gives out is called the output. Therefore, the efficiency of a d.c. machine, like that of any energy-transferring device, is given by;

Efficiency = Output / Input ——————————-①

Output = Input – Losses and Input = Output + Losses

Therefore, the efficiency of a dc machine can also be expressed in the following forms:

Efficiency = (Input – Losses) / Input ———————–②

Efficiency = Output / (Output + Losses) ——————–③

The most obvious method of determining the efficiency of a dc machine is to directly load it and measure the input power and output power. Then we can use Eq ① to determine the efficiency of the machine. This method suffers from three main drawbacks.

- First, this method requires the application of load on the machine.

- Secondly, for machines of large rating, loads of the required sizes may not be available.

- Thirdly, even if it is possible to provide such loads, large power will be dissipated, making it an expensive method.

The most common method of measuring the efficiency of a dc machine is to determine its losses (instead of measuring the input and output on load). We can then use Eq ② or Eq ③ to determine the efficiency of the machine. This method has the obvious advantage of convenience and economy.

Methods for determining Efficiency of DC Machines

There are three different methods of determining the efficiency of a dc machine, namely,

- Direct method,

- Indirect method

- Regenerative method.

Direct Method for Determining Efficiency

By this method, the efficiency and losses of only small machines can be determined. In this method full load is applied to the machine and output is directly measured.

Though this method is very simple in looking but involves complication in the measurement of mechanical power input in the case of a generator, and output in the case of a motor.

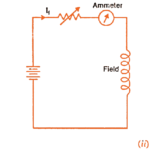

In the case of a generator, the input mechanical power is measured by connecting some form of dynamo-meter to the prime mover and water resistance load is applied.

This method is wasteful since all the input is to be wasted and can only be used in case of small machines due to the difficulty of having enough power and suitable brake arrangements in case of larger machines.

Indirect Method

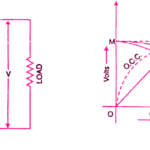

By Indirect method of testing of dc machines, the efficiency of shunt and compound dc machines can be determined.

This method enables the determination of losses without actually loading the machine. The power is required to supply the losses only, so there is no difficulty in applying this method even to very large machines.

Although the efficiency can be calculated with fair accuracy from the results obtained with this method, the disadvantage of this method is that the machine is run light during the test which gives no indication as to the temperature rise on load or to the commutating qualities of the machines.

Regenerative Method

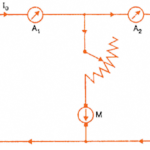

The regenerative method requires two identical machines, one of them operates as a motor and drives the other, which is mechanically coupled to it.

The other machine operates as a generator and feedback power into the supply. Thus the total power drawn from the supply is only for supplying the internal losses of the two machines.

Thus very large machines may be tested as the power required is small.

Important Tests of DC Machines

The important Tests of DC machines are classified as under

- Efficiency By Direct Loading

- Brake test

- Using calibrated generator

- Swinburne’s Method ( Indirect Method )

- Regenerative or Hopkinson’s-Test ( Regenerative Method )

- Retardation or Running down Test

The above tests will be discussed in detail in the coming articles.

Comments are closed.