Instruments can be classified into two main types based on how they present the results of measurements.

- Deflection Type Instruments

- Null Type Instruments

In this article, we will delve into the characteristics, uses, and differences between these two types of instruments, providing readers with a comprehensive understanding of their functions and applications in various fields.

Deflection Type Instruments:

- Deflection type instruments determine the measured quantity based on the deflection of the instrument.

- The measured quantity causes a physical effect that deflects or moves the instrument’s mechanism.

- An opposing force is built into the instrument to counteract this deflection or movement.

- This opposing force increases as the deflection or movement of the instrument increases.

- Balance is achieved when the opposing force equals the force causing the deflection or movement.

- The value of the measured quantity can be determined from the deflection or movement at this point of balance.

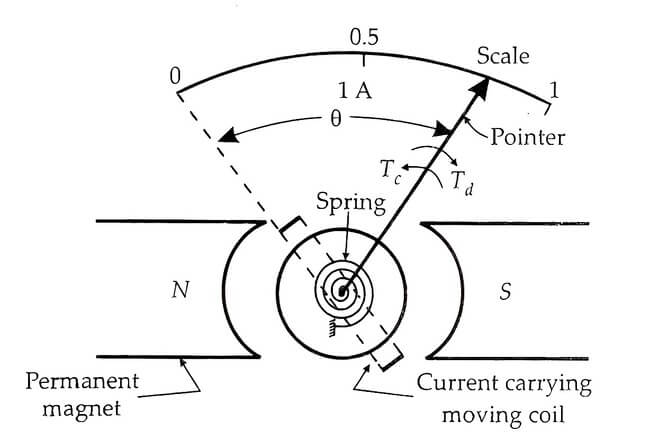

Example: Permanent Magnet Moving Coil (PMMC) Ammeter:

- In a PMMC ammeter, the deflection of the moving coil is proportional to the current (I), the measured quantity.

- The deflecting torque (Td) acting on the moving coil is proportional to the current (I), given by

- Td = GI

where ( G ) is a constant.

- Td = GI

- The opposing force is produced by a spring, with torque ( Tc ) proportional to deflection (θ), given by

- Tc = Kθ

where ( K ) is the spring constant.

- Tc = Kθ

- At balance,

- Td = Tc

GI = Kθ

$\theta = \frac{GI}{K}$

$I = \frac{K}{G}\theta$

- Td = Tc

- The value of the current (I) depends on the deflection (θ) and the constants of the meter (G and K).

- To enable direct reading, the instrument must be calibrated considering the values of G and K.

- Thus, in a deflection type instrument, the value of the measured quantity relies on the instrument’s calibration.

Null Type Instrument

- In a null type instrument, a zero or null indication is used to determine the magnitude of the measured quantity.

- The null condition relies on other known conditions.

- Unlike deflection type instruments, null type instruments aim to maintain the deflection at zero by applying an opposing effect to counteract the effect generated by the measured quantity.

- For the operation of a null type instrument, the following are required:

- The effect produced by the measured quantity.

- The opposing effect, whose value is accurately known, is necessary to determine the numerical value of the measured quantity accurately.

- A detector capable of detecting null conditions, indicating zero deflection (balance conditions) when the effect produced by the measured quantity equals the opposing effect.

- The detector should be capable of displaying imbalance, indicating a condition when the effect produced by the measured quantity is not equal to the opposing effect.

- The detector should have means, whether automatic or manual, for restoring balance.

Example: DC Potentiometer

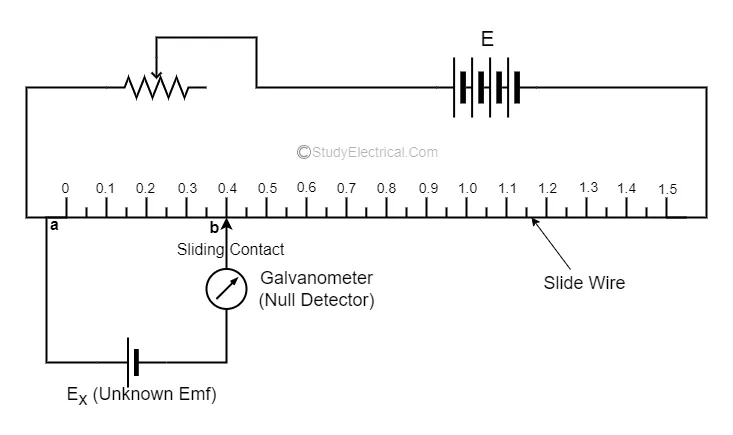

- Figure above depicts the elementary form of an DC potentiometer, a null type instrument used to measure an unknown EMF. Here an unknown EMF (Ex) is measured.

- The slide wire of the potentiometer is calibrated in terms of EMF using a standard EMF source.

- The null detector is a current galvanometer whose deflection is proportional to the imbalance EMF, the difference between the EMF (Eab) across a portion of the slide wire and the unknown EMF (Ex).

- When the two EMFs are equal, there is no current through the galvanometer, indicating zero deflection and null conditions.

- Therefore, the unknown EMF (Ex) is equal to (Eab), directly indicated by the calibrated scale placed alongside the slide wire.

Comparison of Deflection and Null Type Instruments

In various fields of measurement and instrumentation, the choice between null type and deflection type instruments plays a crucial role in determining the accuracy, sensitivity, and suitability for dynamic measurements. This comparison aims to highlight the advantages and disadvantages of each type, providing insights into their respective characteristics and applications.

Accuracy:

- Null Type Instruments:

- Higher accuracy due to calibration with highly accurate standards.

- Deflection Type Instruments:

- Accuracy depends on calibration, which relies on instrument constants usually not known with high accuracy.

Sensitivity:

- Null Type Instruments:

- Balanced out measurement, resulting in highly sensitive detectors covering a small range around the balance point.

- Detectors do not require calibration, only detecting the presence and direction of unbalance.

- Deflection Type Instruments:

- Require larger size and are less sensitive to measure large magnitudes of unknown quantities.

Dynamic Measurements:

- Null Type Instruments:

- Not suitable for dynamic measurements as manipulations are required to obtain null conditions.

- Deflection Type Instruments:

- More suitable for dynamic measurements due to faster response, but may require manipulations.

Automatic Control Instruments:

- There are commercially available automatic control instruments (e.g., self-balancing potentiometers) that maintain continuous null under rapidly changing conditions, eliminating the need for manipulative operations.

| Aspect | Null Type Instruments | Deflection Type Instruments |

|---|---|---|

| Accuracy | Higher accuracy due to calibration with highly accurate standards. | Accuracy depends on calibration, which relies on instrument constants usually not known with high accuracy. |

| Sensitivity | Balanced out measurement, resulting in highly sensitive detectors covering a small range around the balance point. Detectors do not require calibration, only detecting the presence and direction of unbalance. | Require larger size and are less sensitive to measure large magnitudes of unknown quantities. |

| Dynamic Measurements | Not suitable for dynamic measurements as manipulations are required to obtain null conditions. | More suitable for dynamic measurements due to faster response, but may require manipulations. |

| Automatic Control | Commercially available automatic control instruments (e.g., self-balancing potentiometers) maintain continuous null under rapidly changing conditions, eliminating the need for manipulative operations. | – |

Summary:

- Null type instruments are more accurate than deflection type instruments.

- Null type instruments can be highly sensitive compared to deflection type instruments.

- Deflection type instruments are more suited for measurements under dynamic conditions due to their faster response.