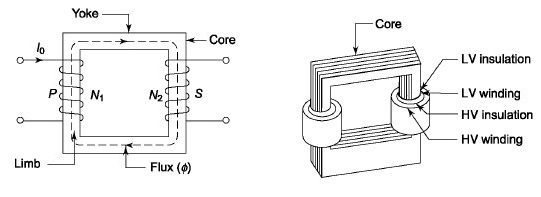

Depending on the type of construction used, the transformers are classified into two categories.

- Core type Transformer

- Shell type Transformer

Difference between Power Transformer and Distribution Transformer

Core Type Transformer

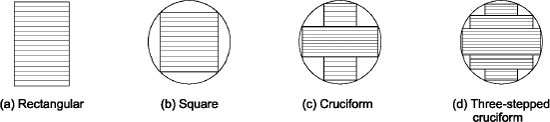

In case of large sized transformers stepped cruciform core with circular cylindrical coils is employed, as illustrated in figure below

Stepped cruciform core employs laminations of different sizes.

Though the cost of manufacturing of such a cruciform core is much greater, but the circular coils that are used are easier to wind and provide more mechanical strength, especially when short-circuit occurs.

Other advantages of using cruciform core are,high space factor and reduced mean length of turns resulting in reduced copper loss.

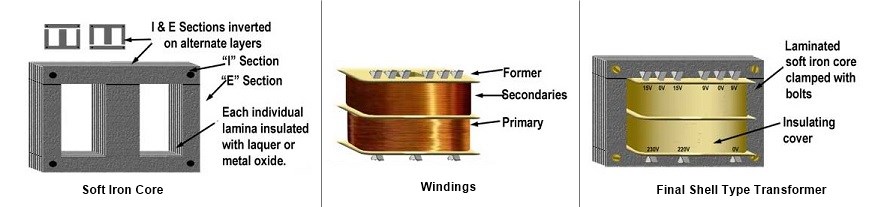

Shell type Transformer

Sandwich type winding is used in such a construction.

Comparison of Core & Shell Type Transformers

| Core Type | Shell Type |

|---|---|

| Easy in design and construction. | Comparatively complex |

| Has low mechanical strength due to non bracing of windings | High mechanical strength. |

| Reduction of leakage reactance is not easily possible. | Reduction of leakage reactance is highly possible |

| The assembly can be easily dismantled for repair work. | It cannot be easily dismantled for repair work. |

| Better heat dissipation from windings. | Heat is not easily dissipated from windings since it is surrounded by core. |

| Has longer mean length of core and shorter mean length of coil turn. Hence best suited for EHV (Extra High Voltage) requirements. | It is not suitable for EHV (Extra High Voltage) requirements. |

Application of Core & Shell Type Transformers

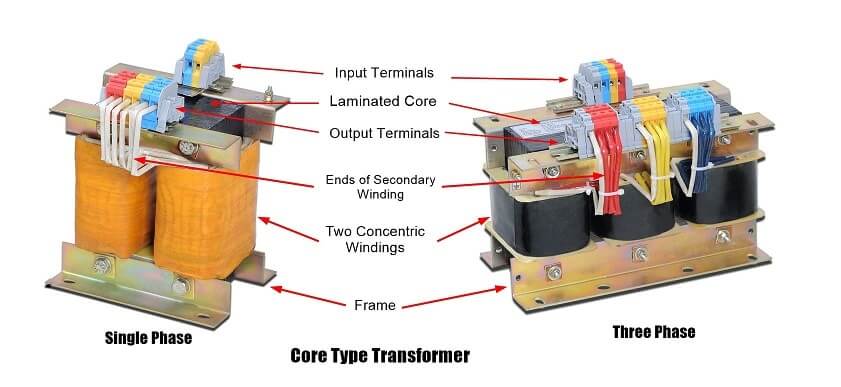

For these reasons, the present practice is to use core type transformers in large high voltage installations.

Why Core Type in HV and Shell Type in LV?

Core type transformers are popular in High voltage applications like Distribution transformers, Power transformers, and obviously auto transformers.

Reasons are, High voltage corresponds to high flux. So, for keeping iron loss down we have to use thicker core. So core type is better choice. At high voltage we require heavy insulation. In core type winding, putting insulation is easier. In fact LV(low voltage) winding it self acts as an insulation between HV (high voltage) winding and core.

Where as, Shell type transformers are popular in Low voltage applications like transformers used in electronic circuits and power electronic converters etc.

Reasons are, at low voltage, comparatively you require more volume for the copper wires than that of iron core. So the windows cut on the laminated sheets have to be of bigger proportion with respect to the whole size of the transformer. So, shell type is a better choice.

In shell type we don’t care about the insulation much and insulation is thin and light. So we can put the winding anyway we want in the shell.

Comments are closed.