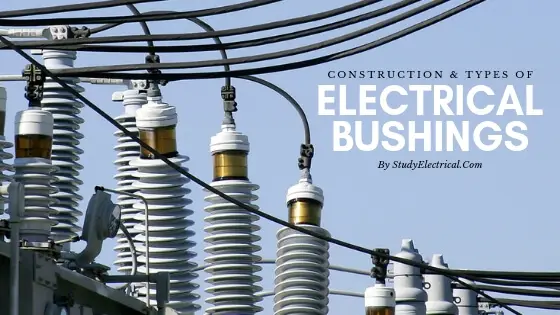

Definition

According to IEEE/ANSI Std. an electrical bushing is defined as “an insulating structure, including a through conductor or providing a central passage for such a conductor, with provision for mounting a barrier, conducting or otherwise, for the purpose of insulating the conductor from the barrier and conducting current from one side of the barrier to the other.”

Purpose of Electrical Bushings

Simply we can say the purpose of an electrical bushing is to transmit electrical power in or out of enclosures, i.e., barriers, of an electrical apparatus such as transformers, circuit breakers, shunt reactors, and power capacitors.

The bushing conductor may take the form of a conductor built directly as a part of the bushing or, alternatively, as a separate conductor that is drawn through, usually through the center of, the bushing.

Since electrical power is the product of voltage and current, insulation in a bushing must be capable of withstanding the voltage at which it is applied, and its current-carrying conductor must be capable of carrying rated current without overheating the adjacent insulation.

For practical reasons, bushings are not rated by the power transmitted through them; rather, they are rated by the maximum voltage and current for which they are designed.

Read Insulating materials in cables.

Types of Electrical Bushings

There are many methods to classify the types of bushings. These classifications are based on practical reasons, which will become apparent in the following discussion in three broad areas. Bushings can be classified:

- According to construction: According to construction bushings are of two types –

- Solid Type or Bulk Type Bushings

- Capacitance-Graded or Condenser Type Bushing

- According to insulating media on ends: This classification depends primarily on the final application of the bushing. It can be classified as

- Air-to-oil bushing

- Air-to-air bushing

- Air-to-SF6 bushings

- SF6-to-oil bushings

- Oil-to-oil bushings

- Air-to-oil bushing

- According to insulation inside the bushing: According to the insulation inside bushing they are classified as –

- Air Insulated Bushings

- Oil Insulated or Oil Filled Bushings

- Oil Impregnated Paper Insulated Bushings

- Cast Insulation Bushings

- Gas Insulated Bushings

Types of Electrical Bushing According to Construction

As we discussed above bushings are classified into to according to their construction. They are

- Solid type (Bulk type) Bushings

- Capacitance-graded (Condenser type) Bushings

1. Solid Type Bushings

The solid-type electrical bushing is typically made with a central conductor and porcelain or epoxy insulators at either end and is used primarily at the lower voltages through 25 kV.

Applications and Limitations of Solid Type Bushings

Solid bushings are commonly used in applications ranging from small distribution transformers and circuit switchers to large generator step-up transformers and hydrogen-cooled power generators.

The primary limitation of the solid bushing is its ability to withstand 60-Hz voltages above 90 kV. Hence, its applications are limited to 25-kV equipment ratings, which have test voltages of 70 kV.

Recent applications require low partial-discharge limits on the 25-kV terminals during transformer test and have caused further restrictions on the use of this type of bushing.

In these cases, either a specially designed solid bushing, with unique grading shielding that enables low inherent partial-discharge levels, or a more expensive capacitance-graded bushing must be used.

2. Capacitance Graded Bushings

Currently, this construction is used for virtually all voltage ratings above 25-kV system voltage and has been used for bushings through 1500-kV system voltage.

Construction of Capacitance Graded Bushings

This construction uses conducting layers at predetermined radial intervals within the oil-impregnated paper or some other insulation material that is located in the space between the central conductor and the insulator.

Different manufacturers have used a variety of materials and methods for making capacitance-graded bushings.

Early methods were to insert concentric porcelain cylinders with metalized surfaces or laminated pressboard tubes with embedded conductive layers.

Later designs used conductive foils, typically aluminum or copper, in oil-impregnated kraft paper.

An alternative method is to print semiconductive ink (different manufacturers have used different conductivities) on all or some of the oil-impregnated kraft-paper wraps.

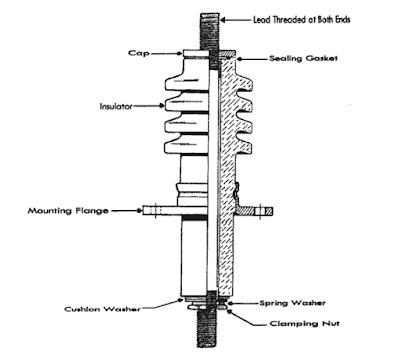

The principal elements are the central circular conductor, onto which the capacitance-graded core is wound; the top and lower insulators; the mounting flange; the oil and an oil-expansion cap; and the top and bottom terminals.

Capacitance-graded bushings involve much more technical and manufacturing details than solid bushings and are therefore more expensive. These details include the insulation/conducting layer system, equipment to wind the capacitor core, and the oil to impregnate the paper insulation.

However, it should be noted that the radial dimension required for the capacitance-graded bushing is much less than the solid construction, and this saves on material within the bushing as well in the apparatus in which the bushing is used.

Also, from a practical standpoint, higher-voltage bushings could not possibly be manufactured with solid construction.

Types of Electrical Bushing Based on End Insulation

As shown in the above section, bushings are classified into six types based on insulating media at the ends. Some of them are explained in this section.

1. Air-to-oil bushing

An air-to-oil bushing has air insulation at one end of the bushing and oil insulation at the other. Since oil is more than twice as strong dielectrically as air at atmospheric pressure, the oil end is approximately half as long (or less) than the air end.

This type of bushing is commonly used between atmospheric air and any oil-filled apparatus.

2. Air-to-air bushing

An air-to-air bushing has air insulation on both ends and is normally used in building applications where one end is exposed to outdoor atmospheric conditions and the other end is exposed to indoor conditions.

Special application bushings have limited usage and include:

- Air-to-SF6 bushings, usually used in SF6-insulated circuit breakers;

- SF6-to-oil bushings used as transitions between SF6 bus ducts and oil-filled apparatus;

- Oil-to-oil bushings, used between oil bus ducts and oil-filled apparatus.

Types According to Insulation inside Electrical Bushing

Still another classification relates to the insulating material used inside the bushing.

In general, these materials can be used in either the solid or capacitance-graded construction, and in several types, more than one of these insulating materials can be used in conjunction.

The following text gives a brief description of these types:

1. Air-Insulated Bushings

Air-insulated bushings generally are used only with air-insulated apparatus and are of the solid construction that employs air at atmospheric pressure between the conductor and the insulators.

2. Oil-Insulated or Oil-Filled Bushings

Oil-insulated or oil-filled bushings have electrical-grade mineral oil between the conductor and the insulators in solid-type bushings.

This oil can be contained within the bushing, or it can be shared with the apparatus in which the bushing is used.

Capacitance-graded bushings also use mineral oil, usually contained within the bushing, between the insulating material and the insulators for the purposes of impregnating the kraft paper and transferring heat from the conducting lead.

3. Oil-Impregnated Paper-Insulated Bushings

Oil-impregnated paper-insulated bushings use the dielectric synergy of mineral oil and electric grades of craft paper to produce a composite material with superior dielectric-withstand characteristics.

This material has been used extensively as the insulating material in capacitance-graded cores for approximately the last 50 years.

4. Resin-Bonded or -Impregnated Paper-Insulated Bushings

Resin-bonded paper-insulated bushings use a resin-coated craft paper to fabricate the capacitance-graded core, whereas resin-impregnated paper-insulated bushings use papers impregnated with resin, which are then used to fabricate the capacitance-graded core.

The latter type of bushing has superior dielectric characteristics, comparable with oil-impregnated paper-insulated bushings.

5. Cast-Insulation Bushings

Cast-insulation bushings are constructed of a solid-cast material with or without an inorganic filler.

These bushings can be either of the solid or capacitance-graded types, although the former type is more representative of the present technology.

6. Gas-Insulated Bushings

Gas-insulated bushings use pressurized gas, such as SF6 gas, to insulate between the central conductor and the flange. This type of bushing is used in SF6 Circuit Breakers.

The bushing is one of the simpler designs and is typically used with circuit breakers.

It uses the same pressurized gas as the circuit breaker, has no capacitance grading, and uses the dimensions and placement of the ground shield to control the electric fields.

Comments are closed.