Industrial accidents continue to plague American workplaces, causing devastating injuries, fatalities, and economic losses. While multiple factors contribute to workplace incidents, inadequate maintenance practices consistently emerge as the primary culprit behind catastrophic industrial failures. Understanding this connection is crucial for preventing future tragedies and protecting workers across all sectors.

The Hidden Danger of Deferred Maintenance

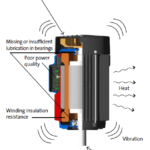

Equipment deterioration doesn’t happen overnight. When companies postpone routine maintenance to cut costs or meet production deadlines, they create a dangerous chain reaction. Worn components stress other parts of the system, leading to unexpected failures that can injure or kill workers. This domino effect transforms minor issues into major hazards that could have been prevented with proper preventive care.

Equipment Failure: The Deadly Reality

Faulty machinery and structural failures account for a significant portion of workplace fatalities across American industries. When maintenance schedules are ignored, critical safety systems fail without warning. Pressure vessels explode, conveyor belts malfunction, and safety guards break down, creating life-threatening situations. Recent workplace safety data reveals that fatal work injuries totaled 5,283 in 2023, representing a 3.7% decrease from the previous year, yet equipment-related incidents remain a persistent threat.

High-Risk Industries and Fatal Patterns

Certain sectors face elevated risks due to the complex machinery and hazardous materials they handle. Manufacturing plants, chemical facilities, and oil refineries operate under extreme conditions where a single plant & refinery accident can result in catastrophic consequences. Investigations into such events frequently identify maintenance deficiencies as a major contributing factor. Meanwhile, the agriculture, forestry, fishing, and hunting industries consistently report the highest fatality rates per 100,000 workers, often linked to poorly maintained heavy equipment and safety systems.

The Transportation Connection

Transportation incidents led to 1,369 workplace deaths in 2022, and many of these tragedies stemmed from poorly maintained vehicles and equipment. Brake failures, tire blowouts, and mechanical malfunctions in company vehicles, forklifts, and mobile equipment create deadly scenarios that proper maintenance could prevent. Regular inspections and timely repairs of transportation equipment save lives and reduce liability.

Economic Consequences Beyond Human Cost

Maintenance neglect creates a financial burden that extends far beyond repair costs. Production shutdowns following accidents can cost millions in lost revenue, while legal settlements and increased insurance premiums strain company resources. Regulatory fines and compliance issues compound these expenses, making prevention through proper maintenance the most cost-effective approach.

Building a Culture of Prevention

Successful maintenance programs require commitment from leadership and engagement from workers at every level. Regular training, adequate staffing, and sufficient budget allocation for maintenance activities create an environment where safety takes priority over short-term profits. Companies that invest in preventive maintenance see reduced accident rates and improved operational efficiency.

The evidence is clear: maintenance neglect serves as the foundation for most industrial accidents in American workplaces. Nowhere is this more devastating than in cases of plant explosions, where a single overlooked inspection or faulty piece of equipment can cause catastrophic harm. By prioritizing equipment care, investing in preventive programs, and nurturing a culture that values worker safety, companies can dramatically reduce accident rates while protecting their most valuable asset—their employees. The cost of prevention will always be less than the price of tragedy, a fact well understood by every plant explosion attorney who fights for victims of such preventable disasters.