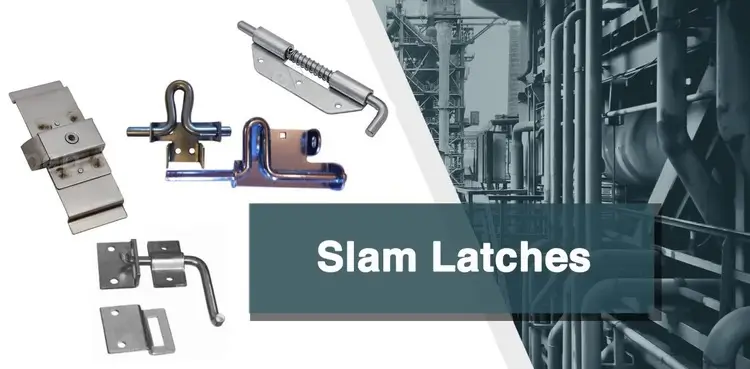

In the manufacturing world, the principles of efficiency and safety together with reliability are of high significance. Although the measurement of these goals involves the identification of numerous parts that need to be incorporated, industrial slam latches remain imperative and sometimes unnoticed parts. These strong and efficient latches guarantee the efficiency of operations in equipment and machinery thus having a safety aspect on manufacturing procedures. This blog post will discuss the essential features of industrial slam latches focusing on their main advantages and the areas in which they can be applied in the sphere of manufacturing.

What is used in Industrial Slam Latches?

Industrial slam latches are fastener products used to lock doors, panels, and other openings including quick and effective operations. They are specially designed to deal with enormous amounts of workload and hostile technological conditions so that they remain efficient and effective for a long time. These latches are conventional for such applications, in which fast and secure shutting is wanted by offering convenience and secure operation to the operators.

Benefits of Industrial Slam Latches

1. Enhanced Safety

Safety is a primary concern in manufacturing environments, and industrial slam latches contribute significantly to maintaining a safe workspace. By ensuring that access points are securely closed, these latches prevent accidental openings that could lead to injuries or equipment damage. Their robust design also means they can withstand impact and wear, providing a reliable safety mechanism over time.

2. Increased Efficiency

In manufacturing, particularly the time is equally as valuable as the money used in the process. Industrial slam latches ensure that access to machines and equipment is fast and that the machines do not experience unnecessary downtime. An inherent design of the handles enables the worker to lock doors and panels without much hassle and faster since there is no need to pull any lever or controls.

3. Durability and Reliability

Industrial settings are usually harsh to equipment and machinery due to the consistent on-the-ground exposure to dust, humidity as well and mechanical load. Industrial slam latches are compatible with these circumstances, they provide a great deal of robustness and dependability. Constructed from materials such as stainless steel or a high-grade plastic they do not corrode or break down and the mechanisms continue to function even in extreme conditions.

Industrial Slam Latches for Your Application

1. Machinery and Equipment

Industrial slam latches come in different forms and are popularly used in various mechanical equipment to ensure the security of panels, doors, and any other cover. This guarantees that moving parts are shielded as well as the chance of accessing internal compartments for service or monitoring will at all times be safe.

2. Storage Solutions

Conveyors and storage equipment such as cabinets and lockers can be found in manufacturing plants and they generally need secure fastening systems. Industrial slam latches offer security, and at the same time, people can open and close in a short space of time to access tools, parts, and supplies among others to enhance working thus the need for their utilization.

3. Transportation and Logistics

Industrial slam latches are also significantly employed in transport and logistic industries to seal the doors, hatches, and compartments of a carriage. They are reliable in satisfying the customer’s desire to have goods that are not affected by vibrations and impacts that are associated with transportation.

Choosing the Right Industrial Slam Latch

1. Consider the Environment

When choosing an industrial slam latch, one needs to carefully take into consideration the conditions that are going to surround the particular latch. This type of effect influence affects the use and durability of the latch, for instance, the temperature and humidity, chemicals among others. This is an indication that some materials and their finishes perform at an optimal they should be used in such an environment.

2. Load and Stress Requirements

Thus, depending on the specific use of a latch, it may be necessary to have a latch that can handle different loads and stress. It is for this reason, that the selected industrial slam latch shall withstand the impact requirement that may be put into it, based on the specific environment that it is used in for example the weight that it shall be handling, the frequency of usage, and the impacts that it is likely to receive.

3. Ease of Use

Incorporation of the industrial slam latch can affect the ease of use and consequently the level of productivity. In choosing latches, pride should be given to the easy use, ease of engagement by applying a low amount of force, and securing the items that it is supposed to secure without necessarily requiring some additional tools or attention.

Conclusion

Industrial slam latches are widely used in the industrial production line as safety accessories that increase productivity and are very durable. Through this guide, manufacturers will be in a position to understand the importance, specification as well as uses of the different latches to arrive at the right choices. Purchasing better quality industrial slam latches guarantees equipment and machinery’s protection and functionality to reduce the risks of accidents and increase production.