Every appliance that dabbles with fluids and gases, from laundry and dry-cleaning gadgets to sterilizers to coffee-making machines, needs a robust internal system to regulate its flow. Whether you work with steam boilers or put out fires, it is essential to control liquid and gases is where solenoid valves come into play.

What are Solenoid Valves?

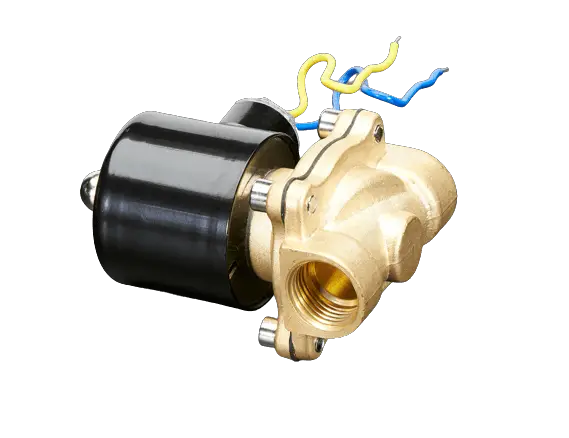

Solenoid valves use electro-mechanical controls in industries that primarily use liquid and gas-based systems to ensure their circulation. They comprise an actuator, a plunger, and a valve body. The actuator positions itself to allow the plunger to open and close the valve. Once the solenoid turns electrical energy into mechanical, an electric current enters the coil, creating a magnetic field.

Parts of Solenoid Valves

The term ‘solenoid valve’ is made of two components: the solenoid (actuator) and the valve body. While every valve body includes the exact parts that might differ in style and composition, solenoids come in various models.

Body

The solenoid’s body is its main framework that supports all the other components, such as the seal, seat, diaphragm, plunger, disc, and bonnet.

Plunger

A solenoid’s plunger is in charge of opening and closing the valve. This magnetic metal makes the solenoid move by consuming or releasing magnetic energy when exposed to magnetic fields. When the solenoid’s coil gains power, it creates a magnetic field that opens or seals the valve.

Coil

One of the solenoid’s crucial parts, the coil, is an insulated copper wire rolled around the plunger. It generates magnetic fields when exposed to current.

Plunger Spring

Once the magnetic field stops, the plunger spring returns to the plunger. Its model and internal system vary according to the valve’s function. For instance, if your appliance requires a sealed valve, the spring will not return to its natural position.

Plunger Tube

The part of the plunger that the coil wraps itself around is its tube. This component is also a magnetic part used to improve the force and effect of the magnetic field formed by the coil. The tube also consists of a fixed core present on its closed side that aids the tube in improving the magnetic energy.

Stem

A solenoid’s stem is the area that joins the valve and plunger. When the coil loops around the plunger, the stem moves with it, keeping the valve intact.

Disc

The disc stops the liquid’s flow when the valve is shut, preventing it from tearing. Since solenoid valves can corrode when not appropriately maintained, discs are usually made of rust-resistant materials like stainless steel.

Diaphragm

Sometimes, manufacturers use a diaphragm instead of discs to stop the fluid’s flow. Diaphragms are flexible, thus detaching the solenoid from the liquid. It also ensures the fluid’s pressure remains controlled and regulated.

Seat

The solenoid’s seat is an opening that latches onto the disc when you close the valve. Since not every valve requires a seat, it might be absent from specific models, depending on the equipment’s role and use. Like a disc, a seat is also made of anti-rust materials to keep it from damaging. A malfunctioning or corroded seat weakens the valve and allows liquid to pass through it.

Bonnet

The bonnet attaches itself to the valve’s top. It allows the plunger tube and stems to pass through and enter the valve.

Bleed Opening

A bleed opening or orifice is another integral solenoid component on the diaphragm. It allows the valve to control the line pressure to regulate its movements.

Seal

The solenoid’s seal removes the solenoid’s body and outside elements from the fluid’s pathway. Various seal designs, such as PTFE and EPDM, are available depending on the liquid’s channel, direction, and usage.

Pilot Channel

Installing a pilot channel into the valve body allows the liquid to flow from the diaphragm into the valve’s lower body.

Benefits of Solenoid Valves

Solenoid valves’ selling points are their safety and smooth operations. Their many benefits make them a popular choice among numerous industries, such as hydrogen and natural compressed gas.

Safe and Secure

All liquid and gas-based applications come with leakage risks. Internal or external leaks can damage the equipment and compromise your safety. Unlike traditional valves with an outer stem, solenoid valves have a moving core run by electric actuators, which prevent leakage by thoroughly closing the valve.

Simple Design

Solenoid valves have a simple yet effective infrastructure that is quick to install and easy to maintain. Additionally, their automated system reduces manual work, making it a cost-friendly choice.

Environmentally Conscious

Solenoid valves require minimal energy to operate, making them ecological appliances. They have a short response time that consumes less power. Additionally, they weigh less, making them easy to maintain and set up.

In Conclusion

Solenoid valves are changing the industry. They make producing and using liquid and gas-run appliances safer and easier. Their robust and straightforward structure, energy-conserving response time, and light weight make them the top choice for all hydrogen, cryogenics, and CNG systems.