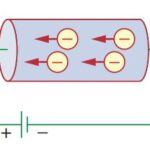

Eddy currents are magnetic fields created whenever a current passes through a conductor. They’re usually found only in particular scenarios. the typically application is the Electrical Conductivity Meter.

Eddy currents can be used for testing virtually any metal. They have several advantages over other testing methods. Eddy currents are fast, safe, and completely non-contact.

Once you’ve decided to implement a testing program at your company, you have to start looking at what you can test and how you can get the most benefit from your testing program. This article will give you some insights into how you can benefit from implementing an eddy current testing program in your workplace.

What Types Of Non-Destructive Testing Methods

There are many different types of non-destructive testing methods that you can use to determine the integrity of any type of material. These include the following:

1. Visual NDT (VT)

This method is probably the oldest and easiest method used. It simply requires a person to visually inspect an area for defects, such as a weld or crack in the metal. The visual inspection can be performed by looking at an object with the naked eye or with a magnifying glass.

2. Ultrasonic NDT (UT)

Ultrasonic NDT is a nondestructive testing method that uses high-frequency sound, which produces acoustic echoes from the body under test that can be used to determine the arrangement, size, composition, and structure of materials.

Ultrasonic NDT is commonly used for measuring the average stress of elastic bodies and ductility tests for springs and fatigue parameters for orthopedic implants and plastic parts.

3. Radiography NDT (RT)

It is also known as Radiation inspection. The technique relies on examining an object to measure characteristic X-ray emissions from the structure through which such beams pass through various thicknesses of shielding material used to reflect or attenuate (such as aluminum).

You need a light source with a spectrometer that will distinguish which particle density gradient plot standard ratios among values may be observed. There are currently four methods used for radiation inspection: visible radiation (IR), infrared radiation (IRS), gamma radiation, and x-rays.

4. Eddy Current NDT (ET)

ET inspection is a type of analysis that uses a magnetic field to conduct mechanical vibrations and fluid flow that can be detected using the phenomenon of eddy currents. Eddy currents are generated in the magnetic field by moving a magnetic material through the area.

5. Magnetic Particle NDT (MT)

6. Acoustic Emission NDT (AE)

7. Dye Penetrant NDT (PT)

8. Leak Testing (LT)

What’s The Advantage Of Eddy Current Testing

1. Eddy current testing is used in the aerospace industry for checking the surface quality of an aero-engine and boiler tubes.

2. Eddy current testing is also used in the automotive industry for checking the surface quality of brake discs and other parts.

3. Eddy current testing is used in the medical equipment industry for checking the quality of surgical instruments and implants.

4. Eddy current testing is also used in the nuclear industry to check reactor internals before installation and after maintenance operations and check welds, pipes, valves, etc., before they are installed into a reactor vessel or tank.

5. Eddy current testing is also used in metallurgical industries such as gold, silver, and copper mining, refining, etc., to check the surface quality of ore grains, etc., before milling or sizing them, etc.

Using eddy currents to measure conductivity changes in these materials during sampling or handling operations e..g., using an eddy-current sampler.

6. Eddy current testing is also used in the oil and gas industry to check the surface quality of drill bits, pipe, valves, etc., before installation or after maintenance operations, as well as to check welds, pipes, valves, etc., before they are installed into a casing or well.

7. Eddy current testing is also used in the mining industry for checking the surface quality of drill bits, pipes, valves, etc., before installation or after maintenance operations, as well as to check welds, pipes, valves, etc., before they are installed into a casing or well.

8. Eddy current testing is also used in stamping industries for checking the surface quality of dies and molds made of steel alloys e..g., cast iron, aluminum die casting, and investment casting alloys e..g., copper-nickel alloy (CNI), etc.

9. Eddy current testing is also used in the electronics industry to check the surface quality of printed circuit boards and other electronic components before assembly and after maintenance operations and to check welds, pipes, valves, etc. before they are installed into a casing or well.

Conclusion

The main thing is to get a feel for it. When you have some experience with this testing method, you will be able to conform promptly and maximize your testing efforts. Always keep in mind the possibility of critical problems when attaining quality control precisely as they should be when using this testing method.

NDT-KITS is a professional ultrasonic flaw detection equipment and probe manufacturing company. We have been in the NDT industry for more than 20 years. Our products cover everything from essential ultrasonic testing tools to complex, full-scale inspection systems, from probes to sensors and from probes to complete inspection systems.

Comments are closed.