Slip rings are small devices that have a very important role in all types of devices, equipment, and machinery that come in all sizes, from the smallest to the largest ones.

They’re a big part of modern engineering and even though slip rings are often overlooked, they’re not only providing an important solution to one problem, but they’re also providing a very versatile purpose that fits almost any type of use, purpose, and needs.

In this post, you’ll learn how slip rings fit modern engineering and how modern engineering would have to come up with a substitute to slip rings if they never existed, so keep on reading as in this post, you’ll learn everything you need to know!

How are Slip Rings Tied to Modern Engineering and Machinery

So how is one small device tied with some of the finest devices, hardware, and machinery produced as a result of modern engineering?

Slip rings have a clear purpose and they’re built to eliminate a problem, and no matter the type of device or machine, if there’s a rotary part to it, slip rings can help be the solution.

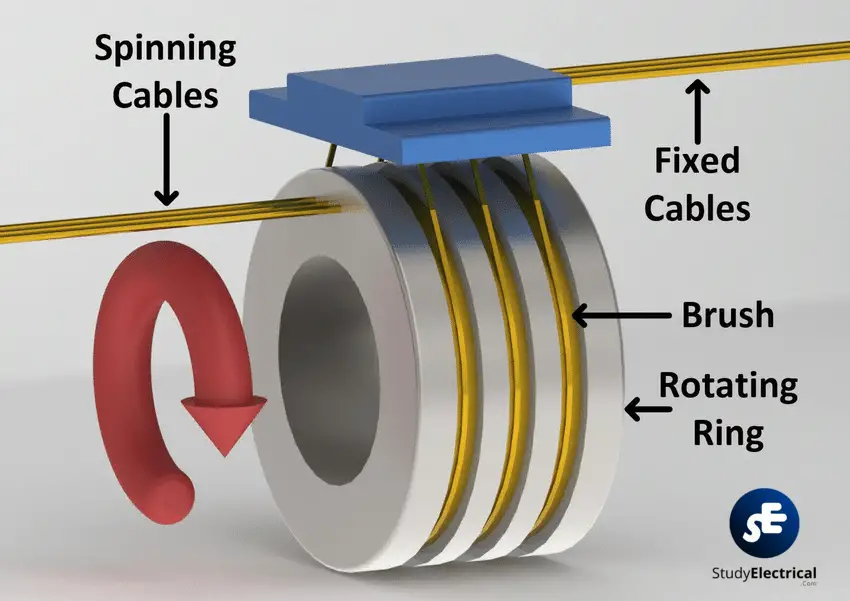

Long story short, slip rings help machinery and all sorts of equipment and devices that have both a stationary and a rotary part to function properly.

They can be found attached to the stationary part of the machine, bridging the gap between the stationary and a rotary part while providing an array of benefits.

And with so many different types and variations, slip rings can fit almost any industry, any type of machine, device, or piece of equipment thanks to their wise design that allows it to fulfill its purpose in so many different ways.

What is Slip Ring’s Purpose and How do they Function

Slip ring was initially invented to solve an issue of wire winding in devices and machines that come with a stationary and rotary part which is where the hazard happens.

Therefore slip rings don’t only remove wires from the joints, but they are also a replacement that helps make a strong contact between the rotary and stationary part of a machine without needing wires that hang around the joints and provide hazard that can lead to a downtime of the machine.

While they solve this issue, slip rings also help transmit electrical signal, power, data, and some slip ring types can even transmit mediums such as fluid, coolant, water, and other.

Slip rings are a very simple invention that’s decades old and yet is still being used in almost all industries you can think of and it can be found in almost all devices that have a rotary part to it.

Typically a slip ring consists of two main components which include a ring (outer part) and a brush or a wiper (the inner part). As the rotation happens, the brush inside the ring slides and as it brushes against the ring, it provides a contact that can transmit power and signal.

Benefits of Slip Rings and Their Use in Real Life Examples

The main benefit of slip rings is the ability to eliminate wire around joints, eliminate hazards, and yet provide a strong contact point that bridges the gap between a stationary and a rotary part of the machine.

However, slip rings have many more benefits due to their versatility. Since they’re so wisely designed, slip rings can be used to control the maximum speed of rotor blades, for example, or to add resistance and slow the speed of an induction motor.

They also offer a slow acceleration even under heavy load capacity so it’s ideal for machines and devices that require a slow start-up, such as heavy machinery.

Slip rings tend to handle high overload easily thanks to their incredible capacity, and since they’re so wisely built, they fit so many industries and are found in many devices.

Some of the most common examples that rely on slip rings include the aerospace industry, medical equipment, monitoring devices, robotics, radar equipment, wind turbines, food and beverage industries, factory automation, and more.

Therefore, it’s not weird to find slip rings in almost any type of device that has a rotary aspect to it.

Slip Ring Types and Advancements

Slip ring is an invention that’s a couple of decades old and yet there are only 6 types that include:

- Pancake ring

- Mercury contact ring

- Through hole ring

- Miniature ring

- Ethernet slip ring

- Fiber optic ring

However, there are plenty of slip ring variations where the main purpose remains the same, yet the versatility and additional benefits and advantages change. The main thing that changes in these types is the medium slip ring can transmit while maintaining a strong contact point between a stationary and a rotary part of a device.

Companies such as Moflon have been producing some of the best slip rings in the industry for over three decades and besides standard slip rings, Moflon also provides custom slip ring solutions for companies that require a slip ring to fit their specific designs.

On top of that, Moflon keeps on striving to advance the use of slip rings by introducing wireless slip rings or brushless slip rings that have no brushes and yet provide a longer lifespan.

Therefore, in the future, we believe slip rings will continue to provide an incredible solution through a simple design but with even better versatility than right now.

Conclusion

With such a simple design and way of use yet with such benefits and advantages, slip rings are definitely a go-to device in the industry wherever there’s a rotary device in question.

Modern engineering is full of product concepts that feature a rotary aspect to it and that’s why we’ll be able to see slip rings being used for a lot longer.

With an easy solution to an important problem and a lot of additional benefits and with continuous improvements with a wide range of fit, slip rings are definitely keeping up with the modern engineering and we’ll be able to see more uses and innovation in the field.