In this article, you will learn about four different types of damping systems namely air friction damping, fluid friction damping, eddy current damping and electromagnetic damping.

Before going into the details you must understand the need for a damping system in a measuring instrument.

In a measuring instrument, the deflecting torque provides some deflection and controlling torque acts in the opposite direction to that of deflecting torque. So before coming to the rest, pointer always oscillates due to inertia, about the equilibrium position. Unless pointer rests, final reading cannot be obtained.

So to bring the pointer to rest within a short time, the damping system is required. The system should provide a damping torque only when the moving system is in motion.

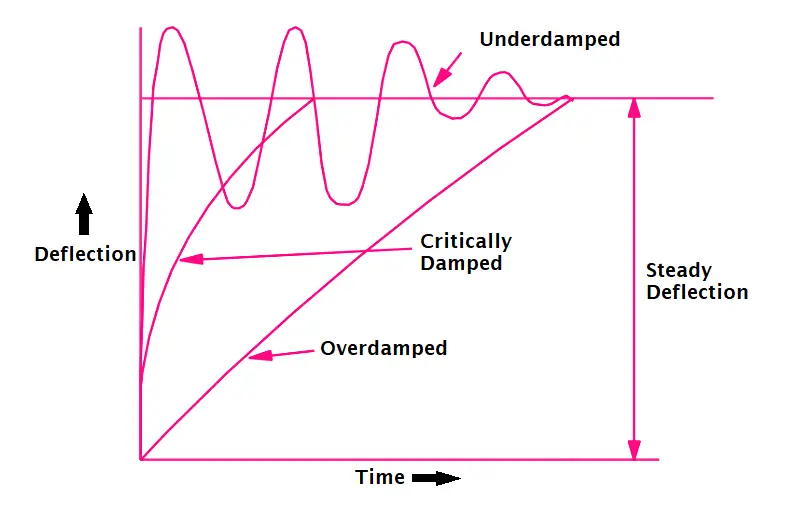

Underdamped, Overdamped and Critically Damped Systems

The damping torque in a damping system should be of such a magnitude that the pointer quickly comes to its final steady position, without overshooting.

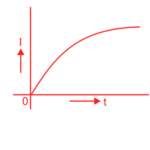

If the instrument is underdamped, the moving system will oscillate about the final steady position with a decreasing amplitude and will take some time before it comes to rest.

When the moving system moves rapidly but smoothly to its final steady position, the instrument is said to be critically damped or dead beat.

If the damping torque is more than what is required for critical damping, the instrument is said to be overdamped.

In an overdamped instrument, the moving system moves slowly to its final steady position in a lethargic fashion. The readings are very tedious to take.

The figure illustrates the way an underdamped, overdamped and critically damped system moves to its final steady position. The damping device should be such that it produces a damping torque only while the moving system is in motion.

To be effective the damping torque should be proportional to the velocity of the moving system but independent of the operating current. It must not affect the controlling torque or increase static friction.

The methods for producing damping torque are :

- Air friction damping

- Fluid friction damping

- Eddy current damping

- Electromagnetic damping.

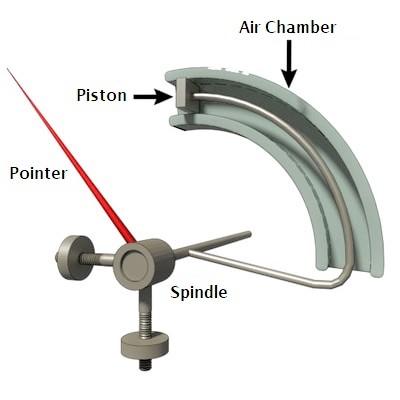

1. Air Friction Damping

There are two types of air friction damping devices.

The above figure shows the first method of air friction damping. It consists of a light aluminium piston that is attached to the moving system. This piston moves in a fixed air chamber which is closed at one end. The clearance between piston and chamber walls is uniform throughout and is very small. When there are oscillations the piston moves into and out of an air chamber.

When the piston moves into the chamber, the air inside is compressed and the pressure of air thus built up, opposes the motion of the piston and hence of the whole of the moving system. When the piston moves out of the air chamber, pressure in closed space falls, and the pressure on the open side of the piston is greater than on the other side. Thus there is again an opposition to the motion.

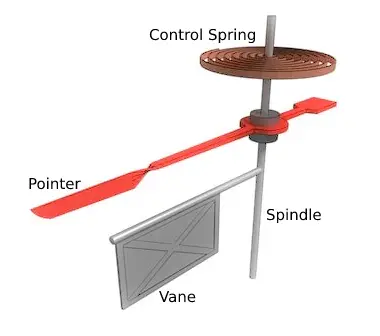

The second type of air friction damping is shown in the above figure. The arrangement consists of an aluminium vane which moves in a quadrant (sector) shaped air chamber. This air chamber is a recess cast in a Bakelite moulding or diecasting.

The chamber is completed by providing a cover plate at the top. The aluminium piston should be carefully fitted so that it does not touch the wall otherwise a serious error will be caused in readings.

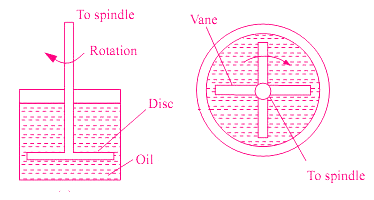

2. Fluid Friction Damping

This form of damping is similar to air friction damping. Oil is used in place of air and as the viscosity of the oil is greater, the damping force is also correspondingly greater.

A disc is attached to the moving system, this disc dips into an oil pot and is completely submerged in oil. When the moving system moves, the disc moves in oil and a frictional drag is produced. This frictional drag always opposes the motion.

In the arrangement shown above a number of vanes are attached to the spindle. These vanes are submerged in oil and move in a vertical plane. This arrangement gives a greater damping torque.

3. Eddy Current Damping

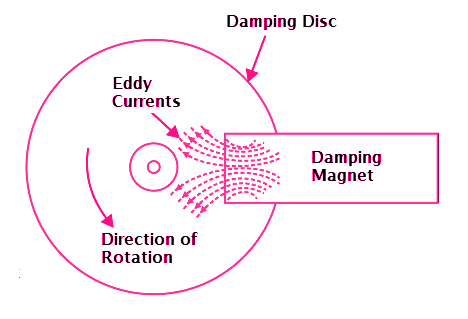

This is also known as electromagnetic damping. When a conductor moves in a magnetic field an emf is induced in it and if a closed path is provided, a current (known as eddy current) flows. This current interacts with the magnetic field to produce an electromagnetic torque that opposes the motion.

This torque is proportional to the strength of the magnetic field and the current produced. The current is proportional to emf which, in turn, is proportional to velocity & the conductor.

Thus if the strength of the magnetic field is constant (if it is produced by a permanent magnet), the torque is proportional to the velocity of the conductor.

4. Electromagnetic Damping

The movement of a coil in a magnetic field produces a current in the coil which interacts with the magnetic field to produce a torque. This torque opposes the movement of the coil and slows the response.

The magnitude of the current and hence the damping torque is dependent upon the resistance of the circuit to which the instrument is connected. The electromagnetic damping is used in galvanometers.

Comparison of Methods of Damping

Air Friction Damping

Air friction damping provides a very simple and cheap method of damping. But care must be taken to see that the piston is not bent or twisted otherwise it will touch the walls of the air chamber thereby causing serious errors due to solid friction which is thus introduced. This method is used in hot wire and moving iron instruments.

Fluid Friction Damping

Fluid friction damping has the advantage that the oil which is required for damping, can be used for insulation purposes in some forms of instruments that are submerged in oil.

A vane moving in oil instead of air does not require the same small clearances to give effective damping and therefore this method is suitable for instruments such as electrostatic type where the movement is suspended rather than pivoted.

Another advantage of fluid friction damping is that due to the upthrust of oil, the load on bearings or suspension is reduced thus reducing frictional errors.

The disadvantages of fluid friction damping are that it can be used only for instruments that are in a vertical position. Also because of the creeping of oil, the instruments cannot be kept clean.

Hence this type of damping can be used for laboratory type electrostatic instruments and there are obvious difficulties in the way of its application to portable instruments.

Eddy Current Damping

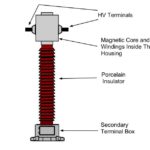

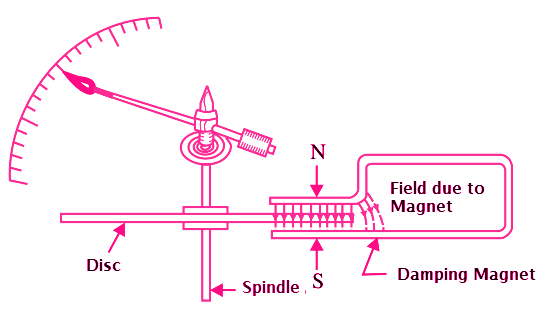

Eddy current damping is the most efficient form of damping. It is very convenient to use in instruments where a metallic disc or a former and a permanent magnet already form part of the operating system eg: PMMC instrument.

For these reasons this method is used in hot wire, moving coil and induction type instruments. This method cannot be used in instruments where the introduction of a permanent magnet required for producing eddy currents will distort the existing magnetic field.

There are two common forms of damping devices :

- A metal former which carries the working coil of the instrument.

- A thin aluminium disc attached to the moving system of the instrument. This disc moves in the field of a permanent magnet.