Capacitors are electrical components composed of two conducting plates, with a slender insulating layer between them. These fundamental devices come in a wide array of designs, styles, and materials, leading to the creation of various types of capacitors.

Understanding the basics of them helps you to choose the capacitor for your application. Before going to each of them, let us understand the basic uses of a capacitor in a circuit.

Capacitors are widely used in electrical and electronic circuits.

In electronic circuits, small value capacitors are used,

- to couple signals between stages of amplifiers.

- as components of electric filters and tuned circuits.

- as parts of power supply systems to smooth rectified current.

In electrical circuits, larger value capacitors are used,

- for energy storage in such applications as strobe lights.

- as parts of some types of electric motors (induction motor).

- for power factor correction in AC power distribution systems

Standard capacitors have a fixed value of capacitance, but adjustable capacitors are frequently used in tuned circuits.

Read how charge is stored in a capacitor.

Types of Capacitors

Now we will learn different types of capacitors and how they are classified. Also in this section, you can find out how these capacitors got their name we call them now.

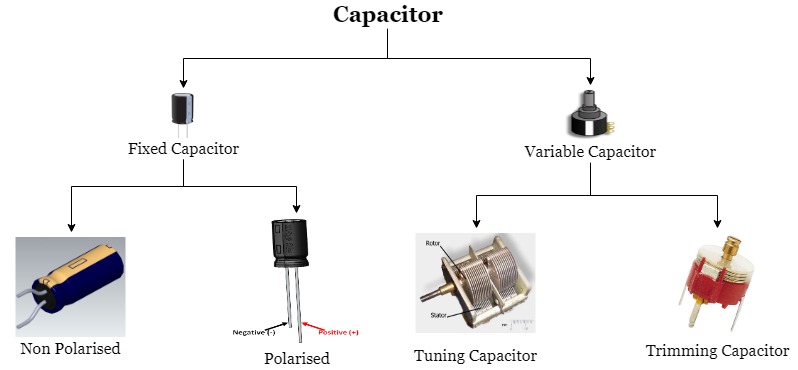

Generally, capacitors are divided into two common groups:

- Fixed Capacitors

- Variable Capacitors

Fixed Capacitors are those capacitors with fixed capacitance values.

While Variable Capacitors have the variable (trimmer) or adjustable (tunable) capacitance values.

Out of these the most important group is fixed capacitors.

The important types of fixed capacitors are:

- Ceramic capacitors

- Film and paper capacitors

- Aluminum, tantalum, and niobium electrolytic capacitors

- Polymer capacitors

- Supercapacitor

- Silver mica, glass, silicon, air-gap, and vacuum capacitors

Many capacitors got their names from the dielectric used in them. But this is not true for all capacitors because some old electrolytic capacitors are named by its cathode construction. So the most used names are simply historical.

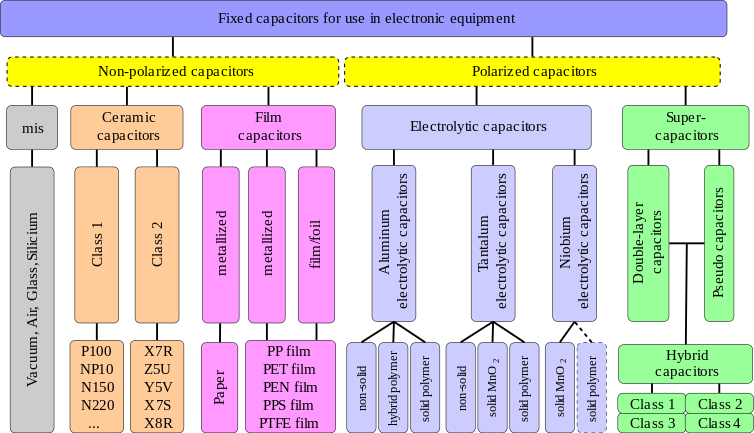

Classification of Fixed Capacitors

Fixed capacitors include polarized and non-polarized. Ceramic and Film capacitors are examples of non-polarized capacitors. Electrolytic and Super Capacitors are included in the group of polarized capacitors.

The complete classification of fixed capacitors is shown in the figure below.

In addition to the above-shown capacitor types, which derived their name from historical development, there are many individual capacitors that have been named based on their application.

The capacitors that derived their name based on their application include the following:

- Power capacitors,

- Motor capacitors,

- DC-link capacitors,

- Suppression capacitors,

- Audio crossover capacitors,

- Lighting ballast capacitors,

- Snubber capacitors,

- Coupling, decoupling or bypassing capacitors.

Often, more than one capacitor family is employed for these applications, e.g. interference suppression can use ceramic capacitors or film capacitors.

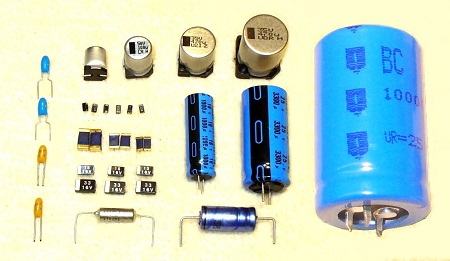

Overview of Different Types of Capacitors

As we explained above, there are many different types of capacitors that can be used. If you know the basic characteristics of each of them you can easily pick a capacitor for your project.

To make your job easy the major types of capacitors are outlined below:

1. Paper capacitor

Paper capacitors are constructed by winding thin sheets of paper alongside thin aluminum foils. To enhance dielectric strength and prevent moisture absorption, the paper is impregnated with oils or waxes. These capacitors are typically enclosed in resin.

The size of paper capacitors tends to be relatively large, primarily due to the thickness of the paper and foil used. In contrast, metallized capacitors employ a different approach to reduce thickness; they directly deposit aluminum onto the dielectric.

These capacitors have a typical capacitance range of 10 nF to 10 mF, a maximum DC voltage rating of 500 V, and a tolerance of ± 10%.

| Property | Description |

|---|---|

| Construction Material | Thin sheets of paper wound with thin aluminum foils |

| Dielectric Enhancement | Paper impregnated with oils or waxes for increased dielectric strength and moisture prevention |

| Encapsulation | Normally encapsulated in resin |

| Size | Typically large due to the thickness of paper and foil |

| Metallized Capacitors | Thickness reduced by direct aluminum deposition on the dielectric |

| Capacitance Range | 10 nF to 10 mF |

| Typical DC Voltage | 500 V (maximum) |

| Tolerance | ± 10% |

This table provides a clear and concise overview of paper capacitors, their construction, features, size, and specifications.

2. Ceramic capacitor

The ceramic capacitor is a type of capacitor that is used in many applications from audio to RF.

Values of ceramic capacitor range from a few picofarads to around 0.1 microfarads. Ceramic capacitor types are by far the most commonly used type of capacitor being cheap and reliable and their loss factor is particularly low although this is dependent on the exact dielectric in use.

Ceramic capacitors typically utilize barium titanate as their dielectric material, although low-loss ceramic capacitors opt for steatite, a natural mineral. These capacitors consist of a thin ceramic plate that’s metallized on both sides, with connecting leads soldered onto it. Multiple layers of lacquer coat the body.

In contrast, modern monolithic ceramic capacitors are composed of alternating layers of thin ceramic dielectric and electrodes, which are fired and compressed to create a single solid block. These monolithic capacitors are notably compact in size.

Here are the specifications in a concise format:

| Property | Description |

|---|---|

| Dielectric Material | Ceramic (Barium Titanate for regular, Steatite for low-loss) |

| Construction Method | Thin ceramic plate metallized on both sides, soldered leads, multiple lacquer layers (regular and low-loss); Monolithic block with alternating layers (monolithic) |

| Capacitance Range | (a) Low Loss (Steatite): 5 pF to 10 nF |

| (b) Barium Titanate: 5 pF to 1 mF | |

| (c) Monolithic: 1 nF to 47 mF | |

| Typical Voltage Range | (a) and (b): 60 V to 10 kV |

| (c): 60 V to 400 V | |

| Tolerance | ± 10% to ± 20% |

This presentation offers a succinct summary of ceramic capacitors, their dielectric materials, construction methods, capacitance and voltage ranges, as well as tolerance levels.

3. Electrolytic capacitor

Electrolytic capacitors are a type of capacitor that is polarised. They are able to offer high capacitance values – typically above 1μF.

High-value capacitors are typically of the electrolytic type. They’re constructed using a metal foil, with a surface that develops a metal oxide film through an anodic process. This anodized foil is immersed in an electrolytic solution, and the oxide film serves as the dielectric separating the metal and the solution. The compact size and high capacitance of electrolytic capacitors result from having an extremely thin dielectric layer.

There are two main types of electrolytic capacitors:

- Aluminum: These come in plain foil, etched foil, and solid forms.

- Tantalum: Available in solid and wet-sintered variants.

These capacitors are most widely used for low-frequency applications – power supplies, decoupling, and audio coupling applications as they have a frequency limit if around 100 kHz.

| Property | Description |

|---|---|

| Type of Capacitor | Electrolytic |

| Construction Material | Metal foil with anodic metal oxide film |

| Dielectric Material | Metal oxide film formed through anodic process |

| Dielectric Separation | Oxide film separates metal foil and electrolytic solution |

| Capacitance | High due to very thin dielectric layer |

| Types of Electrolytic Capacitors | 1. Aluminum: Plain foil, etched foil, solid |

| 2. Tantalum: Solid, wet-sintered |

4. Tantalum capacitor

Since tantalum capacitor is a type of electrolytic capacitor, they are also polarised and offer a very high capacitance level for their volume.

However, this type of capacitor is very intolerant of being reversely biased, often exploding when placed under stress.

This type of capacitor must also not be subject to high ripple currents or voltages above their working voltage.

They are available in both leaded and surface mount formats.

5. Silver Mica Capacitor

A mica capacitor is made by directly metallizing the thin sheets of mica with silver and stacking together several such sheets to make the complete capacitor. The assembly is encapsulated in resin or molded in plastic

Silver mica capacitors are not as widely used these days, but they still offer very high levels of stability, low loss, and accuracy where space is not an issue.

They are primarily used for RF applications and they are limited to maximum values of 1000 pF or so.

| Construction Material | Mica |

| Metallization | Directly metallized with silver |

| Construction Method | Stacked sheets encapsulated in resin or molded in plastic |

| Capacitance Range | 5 pF to 10 nF |

| Typical DC Voltage | 50 V to 500 V |

| Tolerance | ± 0.5% |

6. Polystyrene Film Capacitor

Polystyrene capacitors are a relatively cheap capacitor but offer a close tolerance capacitor where needed.

They are tubular in shape resulting from the fact that the plate / dielectric sandwich is rolled together, but this adds inductance limiting their frequency response to a few hundred kHz.

They are generally only available as leaded electronics components.

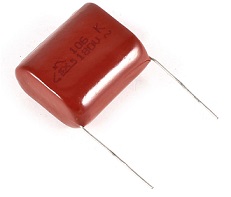

7. Polyester Film Capacitor

Polyester film capacitors are used where cost is a consideration as they do not offer a high tolerance.

Many polyester film capacitors have a tolerance of 5% or 10%, which is adequate for many applications. They are generally only available as leaded electronics components.

8. Metallised Polyester Film Capacitor

This type of capacitor is essentially a form of polyester film capacitor where the polyester films themselves are metalized.

The advantage of using this process is that because their electrodes are thin, the overall capacitor can be contained within a relatively small package.

The metalized polyester film capacitors are generally only available as leaded electronics components.

9. Polycarbonate Capacitor

The polycarbonate capacitors have been used in applications where reliability and performance are critical.

It enables us to make high tolerance capacitors. These capacitors will hold their capacitance value over time.

In addition, they have a low dissipation factor, and they remain stable over a wide temperature range, many being specified from -55°C to +125°C.

However, the manufacture of polycarbonate dielectric has ceased and their production is now very limited.

10. Polypropylene Capacitor

The polypropylene capacitor is sometimes used when a higher tolerance type of capacitor is necessary than polyester capacitors offer.

As the name implies, this capacitor uses a polypropylene film for the dielectric. One of the advantages of the capacitor is that there is very little change of capacitance with time and voltage applied.

This type of capacitor is also used for low frequencies. Usually with 100 kHz or so being the upper limit. They are generally only available as leaded electronics components.

11. Glass Capacitors

As the name implies, this capacitor type uses glass as the dielectric. Glass capacitors are generally expensive.

Although expensive, these capacitors offer very high levels of performance in terms of extremely low loss, high RF current capability, no piezo-electric noise, and other features.

These features make them ideal for many performance RF applications.

12. SuperCap

A SuperCap is also known as a supercapacitor or ultracapacitor.

As the name implies these capacitors have very large values of capacitance, of up to several thousand Farads.

SuperCap finds uses for providing a memory hold-up supply and also within automotive applications.

Comments are closed.