Sensors are essential in various applications, from domestic gadgets to industrial gear. Among these sensors, the thermistor sensor is notable for its versatility and accuracy in temperature measurement.

This article looks into the exciting world of thermistor sensors, discussing their operating principles, types, uses, benefits, and challenges. By the conclusion, you’ll have a solid knowledge of why thermistor sensors are essential in modern technology.

What is a Thermistor Sensor?

A thermistor sensor is a resistor whose resistance changes dramatically with temperature. The term “thermistor” is a combination of “thermal” and “resistor,” referring to its principal function of monitoring temperature changes. Unlike other temperature sensors, such as thermocouples or RTDs (Resistance Temperature Detectors), thermistor sensors are susceptible to slight temperature variations, making them excellent for applications that require precise temperature monitoring.

Working Principle of Thermistor Sensors

Thermistor sensors work because the electrical resistance of certain materials varies with temperature. There are two types of thermistor sensors: negative temperature coefficient (NTC) and positive temperature coefficient (PTC).

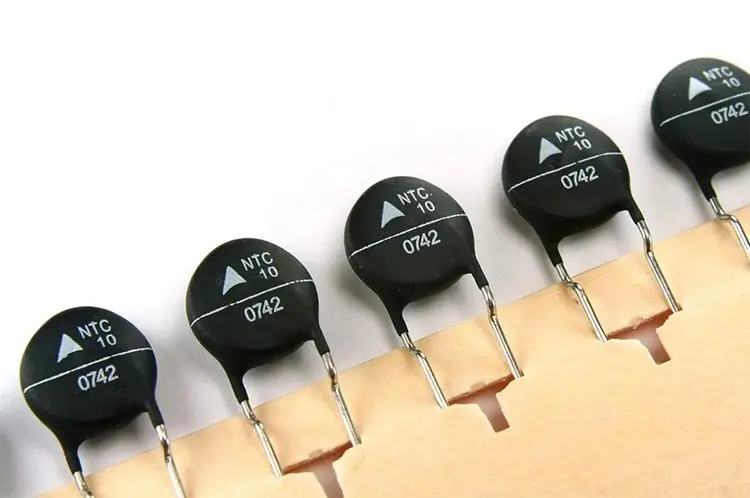

Negative Temperature Coefficient (NTC) Thermistors

NTC thermistors show a decrease in resistance as temperature rises. This characteristic results from the increased availability of charge carriers (electrons) at higher temperatures, which reduces resistance. NTC thermistors sensor are widely employed in applications requiring precise temperature control, such as medical devices and environmental monitoring systems.

Positive Temperature Coefficient (PTC) Thermistors

In contrast, PTC thermistors increase in resistance as the temperature rises. PTC thermistors are commonly employed in temperature measurement and as overcurrent protectors in electrical circuits because their resistance increases dramatically at a given temperature, restricting current flow and preventing damage.

Types of Thermistor Sensors

Thermistor sensors are available in various configurations, each suited to a different purpose. The most popular types are:

Bead Thermistors

Bead thermistors are small, bead-shaped sensors usually sealed in epoxy or glass. They are very responsive and employed in applications requiring quick temperature measurements, including medical probes and consumer electronics.

Disc and Chip Thermistors

Disc and chip thermistors are larger and have more power dissipation capacity. They are widely utilized in industrial applications, including motor protection and battery management systems.

Probe Thermistors

Probe thermistors are enclosed in a metal or plastic sheath, which protects them from severe conditions. These sensors are commonly utilized in HVAC systems, automobile applications, and food safety monitoring.

Applications of Thermistor Sensors

The adaptability of thermistor sensors allows them to be used in a wide variety of sectors.

Medical Devices

In the medical field, thermistor sensors are utilized in digital thermometers, incubators, and patient monitoring systems. Their great sensitivity and precision ensure that temperature readings are consistent, which is crucial for patient care.

Automotive Industry

Thermistor sensors are used extensively in automotive applications such as engine temperature monitoring, climate control systems, and battery management in electric vehicles. Their ability to deliver quick and accurate temperature data improves vehicle performance and safety.

Consumer Electronics

Thermistor sensors are used in various consumer electrical devices, including cell phones and refrigerators. They help to control temperature, ensuring peak performance and reducing overheating.

Industrial Applications

Thermistor sensors are utilized in industrial settings to monitor and regulate temperature-dependent processes. In manufacturing plants, applications include motor protection, HVAC systems, and environmental monitoring.

Environmental Monitoring

Weather stations, agricultural monitoring systems, and oceanic studies use thermometer sensors to reliably record temperature differences. Their dependability and accuracy make them excellent for long-term environmental data collection.

Advantages of Thermistor Sensors

Thermistor sensors have significant advantages, making them popular in various applications.

High Sensitivity

Thermistor sensors are susceptible to minor temperature changes, enabling accurate temperature measurements. As a result, they are ideal for applications requiring high accuracy.

Fast Response Time

Thermistor sensors’ tiny size and thermal mass allow them to respond rapidly to temperature changes. This feature is essential in applications that require real-time temperature monitoring.

Wide Temperature Range

Thermistor sensors can work across a wide temperature range, from cryogenic to several hundred degrees Celsius. Their adaptability makes them appropriate for a wide range of applications.

Cost-Effective

Thermistor sensors are less expensive than conventional temperature sensors, making them an appealing option for budget-conscious applications.

Durable and Reliable

Thermistor sensors are durable and can tolerate extreme conditions, assuring long-term dependability. Their toughness makes them perfect for industrial and automotive applications.

Challenges and Limitations

Despite their various benefits, thermistor sensors do confront some obstacles and restrictions.

Non-Linear Response

One of the main issues with thermistor sensors is their non-linear resistance-temperature connection. This nonlinearity complicates signal processing and calibration, necessitating additional circuitry or algorithms to linearize the response.

Limited Temperature Range for Some Types

Although thermistor sensors can work over a wide temperature range, some varieties, such as NTC thermistors, may have lower temperatures than other sensors, such as RTDs. This shortcoming may limit its application in harsh temperature conditions.

Self-Heating Effect

When a current flows through a thermometer sensor, it can self-heat, resulting in false temperature readings. This effect must be reduced with proper design and application considerations.

Aging and Drift

Thermistor sensors can age and drift over time, altering their resistance characteristics. Regular calibration and maintenance are required to ensure accurate measurements.

Choosing the Right Thermistor Sensor

Selecting the appropriate thermistor sensor for a particular application entails examining several parameters, including:

Temperature Range

Determine the temperature range needed for your application and select a thermistor sensor that can perform efficiently within it.

Accuracy and Precision

Consider the accuracy and precision required for temperature measurements. NTC thermistors are often more accurate for precision applications, while PTC thermistors are appropriate for overcurrent protection.

Response Time

Determine the response time needed for your application. Bead thermistors have short response times, making them perfect for rapid temperature changes.

Environmental Conditions

Consider the ambient conditions to which the sensor will be exposed, such as humidity, vibration, and chemical exposure. Choose a sensor that has adequate encapsulation and protection.

Cost

Evaluate the cost of the thermistor sensor in relation to the needs of your application. While thermistor sensors are generally inexpensive, some varieties or configurations may cost more.

Innovations in Thermistor Sensor Technology

As technology advances, thermistor sensors undergo substantial improvements that improve their capabilities and broaden their range of uses. These advances ensure that thermistor sensors stay at the cutting edge of temperature-detecting technology.

Nanotechnology Integration

Nanotechnology is transforming the design and function of thermistor sensors. Nanomaterials enable manufacturers to create thermistor sensors with higher sensitivity and faster reaction times. For example, nanostructured thermistors can detect minute temperature changes more accurately than standard thermistors, making them excellent for sophisticated medical diagnostics and research applications.

Flexible and Wearable Thermistors

Developing flexible and wearable thermistor sensors is a game changer, especially in healthcare. These sensors can be integrated into wearable devices like smartwatches and fitness trackers to constantly monitor body temperature. This real-time data can be critical for early disease detection and chronic condition monitoring. Furthermore, flexible thermistor sensors can be incorporated into garments, providing a non-invasive form of continuous health monitoring.

Wireless Thermistor Sensors

Wireless thermistor sensors are gaining popularity due to their simplicity and ease of usage. These sensors can wirelessly send temperature data to a central system, reducing the need for complex wiring. This breakthrough is especially useful in industrial and environmental monitoring applications, where wired sensors can be challenging to install and maintain. Wireless thermistor sensors can also be linked to smart home systems to provide continuous and automated temperature control.

Energy Harvesting Thermistor Sensors

Energy harvesting is a promising technology that enables thermistor sensors to create power from their surroundings, such as temperature differences or vibrations. These self-powered sensors don’t require external power sources or frequent battery replacements, making them ideal for remote or inaccessible areas. Energy-harvesting thermistor sensors are being investigated for environmental monitoring, infrastructure health monitoring, and space exploration.

Enhanced Durability and Environmental Resistance

Thermistor sensors are increasingly being built to survive extreme environmental conditions such as high temperatures, humidity, and chemical exposure. Manufacturers can create high-accuracy and reliability thermistor sensors in harsh settings using modern materials and protective coatings. This increased durability is especially useful in industrial applications, where sensors are frequently exposed to hostile environments.

The Role of Thermistor Sensors in Emerging Technologies

Thermistor sensors are critical to the development and operation of many developing technologies. Their capacity to produce exact temperature measurements is essential to the growth of several cutting-edge fields.

Autonomous Vehicles

To operate securely and efficiently, autonomous cars rely on many sensors. Thermistor sensors monitor the temperature of essential components such as batteries, motors, and electronic controllers. Maintaining ideal temperature conditions is critical for the performance and durability of these components, assuring the safety and dependability of self-driving vehicles.

Renewable Energy Systems

Thermistor sensors are essential for monitoring and controlling temperature in renewable energy systems such as solar panels and wind turbines. Overheating can drastically degrade the efficiency and longevity of these systems. Thermistor sensors give real-time temperature data, allowing for automated cooling methods and optimal performance. Additionally, thermistor sensors are utilized in geothermal energy systems to monitor subsurface temperatures, allowing for more efficient energy extraction.

Advanced Manufacturing

Thermistor sensors are critical in sophisticated industrial processes that demand accurate temperature control. Precise temperature control is essential for product quality and consistency in semiconductor manufacturing, aircraft, and medicines. Thermistor sensors allow for real-time temperature monitoring and control, ensuring that production processes meet tight criteria.

Smart Agriculture

Incorporating thermistor sensors into innovative agriculture operations is changing how we cultivate crops and manage cattle. Thermistor sensors in crop cultivation detect soil and ambient temperatures, allowing farmers to improve irrigation, fertilization, and insect control operations. Thermistor sensors are used in livestock management to monitor the health and well-being of animals by collecting data on body temperature and surrounding circumstances. This information enables farmers to provide ideal living circumstances for their cattle, increasing productivity and animal welfare.

Final Words

Thermistor sensors are critical to modern technology, providing precise and dependable temperature measurements across various applications. Their sensitivity, quick response time, and low cost make them appealing to multiple industries, including healthcare and automotive. While they confront obstacles such as nonlinearity and self-heating, constant materials and signal processing advances improve their performance. As technology advances, thermistor sensors will play a more critical part in our networked environment.