Why Washing Machine Repair Matters

Washing machine repair is one of those services you never think about until your laundry routine comes to a screeching halt.

Most households rely heavily on this appliance, and when it stops working, the ripple effect is immediate—piles of clothes stack up, and frustration sets in.

What often gets overlooked is how much these breakdowns can teach us about electrical circuits, safety, and preventive maintenance.

I remember a neighbor calling me late one evening because her washer stopped mid-cycle.

The machine wouldn’t drain, and she panicked because she had guests visiting the next morning.

What seemed like a crisis turned into a learning opportunity about how a simple electrical connection can impact an entire appliance.

Washing machine repair is more than just fixing a broken unit—it’s about understanding how power flows, where weaknesses show up, and how small issues can turn into expensive repairs if ignored.

Common Issues That Lead to Repairs

Electrical circuits inside washers are not overly complex, but they are sensitive.

A loose wire, a faulty switch, or even a worn-out fuse can cause the entire machine to shut down.

In many cases, the motor stops turning because the safety switch on the lid malfunctions.

I once helped troubleshoot a top-loader that wouldn’t spin.

The owner thought the motor was fried, but it turned out to be a faulty lid switch costing less than a dinner out.

That moment made me realize how electrical circuits, even in small appliances, play an oversized role in everyday life.

Another common failure point is the control board.

It’s essentially the brain of the washer, regulating everything from water levels to spin cycles.

When it goes bad, the lights may flicker, the cycles stop halfway, or the washer refuses to start altogether.

Lessons From Clermont Appliance Repairs

In Clermont, I watched a repair technician handle a front-loading machine that wouldn’t start.

The problem? A tripped circuit caused by an overloaded outlet.

The family had plugged the washer and dryer into the same extension cord—something most manuals warn against.

That small mistake overloaded the circuit, leading to repeated shutdowns.

The technician not only fixed the problem but also educated the homeowners about proper outlet use.

It highlighted how electrical awareness is as critical as the repair itself.

When DIY Makes Sense—and When It Doesn’t

Trying a DIY approach can save money, but it requires caution.

Changing a door seal, unclogging a drain hose, or tightening connections are all reasonable tasks for someone handy.

However, tackling electrical board replacements or rewiring should be left to professionals.

I once attempted to replace a burned wire on an older washer.

The moment I touched the connection, a spark shot across the board.

Luckily, I had unplugged the machine beforehand, or that story might have ended differently.

That experience taught me respect for even the simplest circuits inside home appliances.

Preventive Steps To Reduce Breakdowns

Prevention is the most underrated part of appliance care.

Simple steps like not overloading the drum, checking hoses regularly, and keeping the machine level extend its life significantly.

Another underrated tip is plugging the washer into a surge protector, especially in areas prone to electrical spikes.

A friend of mine ignored these steps and faced repeated repairs.

His washer motor burned out twice in under three years because of constant overloading.

Contrast that with another family I know, who carefully maintain their machines and haven’t needed a major repair in over a decade.

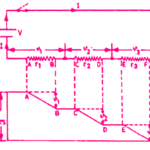

Electrical Circuit Basics Learned From Appliances

Studying washers up close shows how electricity powers motors, heaters, and sensors in harmony.

When one component fails, the entire cycle collapses—like a domino effect.

It’s similar to larger electrical systems: every part matters, no matter how small.

Repairing appliances taught me how to trace current flow, test continuity, and understand resistance in practical terms.

Those lessons, though learned in kitchens and laundry rooms, translate into broader knowledge about home electrical safety.

Real-Life Case Study: The Quick Fix

One of the most memorable cases involved a single mother whose washer wouldn’t drain.

She feared a costly replacement, but the issue turned out to be a sock jammed in the pump.

The technician removed it within minutes, and the washer was back in action.

That moment wasn’t just about relief.

It showed how sometimes the problem isn’t electrical at all—but knowing how to diagnose through elimination is just as valuable.

The Bigger Picture

Washing machines are more than household appliances—they’re everyday teachers of electrical awareness.

Each repair, whether in West Hollywood or Clermont, tells a story about safety, maintenance, and problem-solving.

From overloaded outlets to faulty switches, the lessons go beyond laundry and into practical life skills.

When a washer breaks, it’s easy to see only inconvenience.

But if you look deeper, every repair carries insights into how electricity works and why respect for circuits matters.

That’s the real takeaway: behind every hum of a working washer lies a network of connections we often take for granted.