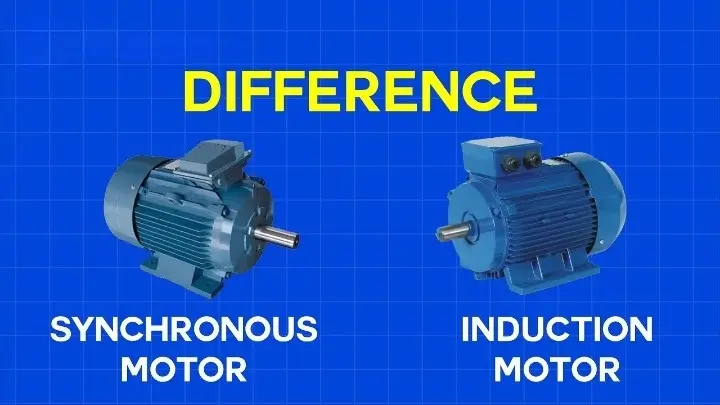

Understanding the differences between induction motors and synchronous motors is crucial for selecting the right type of motor for various industrial applications. Both types of motors are widely used in the industry, but they operate on different principles and have distinct characteristics. This article explores the key distinctions between induction motors and synchronous motors to help you make informed decisions.

Definition and Overview of Induction Motors

What is an Induction Motor?

An induction motor, also known as an asynchronous motor, operates on the principle of electromagnetic induction. It is the most common type of AC motor used in various applications due to its simplicity and durability.

How Induction Motors Work

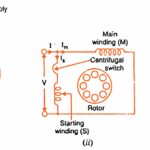

Induction motors work by inducing an electromagnetic field in the rotor through the stator’s rotating magnetic field. The rotor does not receive electrical power directly; instead, it rotates due to the induced current caused by the stator’s magnetic field.

Types of Induction Motors

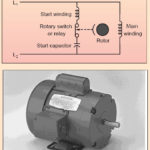

- Single-Phase Induction Motor: Used in domestic appliances and small machinery.

- Three-Phase Induction Motor: Commonly used in industrial applications due to its efficiency and power.

Definition and Overview of Synchronous Motors

What is a Synchronous Motor?

A synchronous motor is an AC motor that operates at a constant speed, synchronized with the frequency of the supply current. Unlike induction motors, synchronous motors run at a speed equal to the supply frequency.

How Synchronous Motors Work

Synchronous motors operate by applying a three-phase AC supply to the stator, which generates a rotating magnetic field. The rotor, typically containing windings or permanent magnets, is magnetically locked with the rotating field and rotates at the same speed as the stator’s magnetic field.

Types of Synchronous Motors

- Non-Excited Synchronous Motor: Uses permanent magnets in the rotor.

- Direct-Current (DC) Excited Synchronous Motor: Requires a DC power source for the rotor windings.

Key Differences Between Induction Motors and Synchronous Motors

Principle of Operation

- Induction Motor: Operates based on electromagnetic induction where the rotor current is induced by the stator’s magnetic field.

- Synchronous Motor: Operates by synchronizing the rotor speed with the stator’s rotating magnetic field.

Speed

- Induction Motor: Speed varies with the load and is always less than the synchronous speed.

- Synchronous Motor: Runs at a constant speed regardless of the load, equal to the synchronous speed.

Efficiency

- Induction Motor: Generally less efficient due to slip and rotor losses.

- Synchronous Motor: More efficient, especially under high load conditions. At levels above 10MW, synchronous motors are more efficient due to the superior mechanical performance of the solid steel rotor forging, allowing them to run at much higher speeds than induction motors.

Power Factor Correction

- Synchronous Motor: Offers the benefit of plant power factor correction by overexciting the units, which can also absorb vars. This is particularly advantageous for low-speed motors where induction motors tend to have a poor power factor.

Starting Mechanism

- Induction Motor: Simple starting mechanism, often self-starting.

- Synchronous Motor: Requires additional starting mechanisms such as an auxiliary motor or damper windings.

Applications

- Induction Motor: Widely used in pumps, fans, compressors, and conveyor systems.

- Synchronous Motor: Used in applications requiring constant speed such as clocks, record players, and industrial drives.

Pros and Cons of Each

Induction Motor

Pros:

- Robust and durable.

- Lower cost and easier to maintain.

Cons: - Lower efficiency due to slip.

- Speed varies with load.

Synchronous Motor

Pros:

- High efficiency with no slip.

- Constant speed operation.

Cons: - More complex starting mechanisms.

- Higher initial cost and maintenance requirements.

Pros and Cons of Small Synchronous Motors

Pros

- Small Synchronous Motors: Ideal for applications where maintaining an accurate fixed speed is crucial without the need for complex speed control electronics. Examples include clock and timer motors, projector drives, turntables, and indexing conveyors. They are slightly more efficient and smaller than their induction counterparts and can turn at lower speeds without additional electronics.

- High Torque: By simply controlling the field strength, either with permanent magnets or slip rings on the rotor, a specific speed can be accurately maintained with relatively high torque for the physical size. They are sometimes used in servo applications, especially when slow motor speeds are necessary.

Cons

- Cost: Synchronous motors are generally more expensive and have lower off-the-shelf availability in one-off applications compared to the ubiquitous induction motor. However, in OEM applications, the cost and availability issues become negotiating points.

Comparison Table

To better illustrate the differences, here’s a comparison table:

| Feature | Induction Motor | Synchronous Motor |

|---|---|---|

| Principle of Operation | Electromagnetic induction | Synchronization with the stator’s magnetic field |

| Speed | Varies with load, less than synchronous speed | Constant speed, equal to synchronous speed |

| Efficiency | Generally less efficient due to slip | More efficient, especially under high load |

| Starting Mechanism | Simple, often self-starting | Requires additional starting mechanisms |

| Applications | Pumps, fans, compressors, conveyor systems | Clocks, record players, industrial drives |

| Pros | Robust, durable, lower cost, easy to maintain | High efficiency, constant speed operation |

| Cons | Lower efficiency, speed varies with load | Complex starting, higher cost, more maintenance |

Conclusion

In summary, while both induction motors and synchronous motors have their unique advantages and are suited for different applications, your choice will depend on the specific requirements of your project. Induction motors are favored for their simplicity and cost-effectiveness, whereas synchronous motors are chosen for applications needing constant speed and higher efficiency.

Call to Action

Share your thoughts in the comments below and check out our other articles on motor types and their applications to help you make the best choice for your needs!