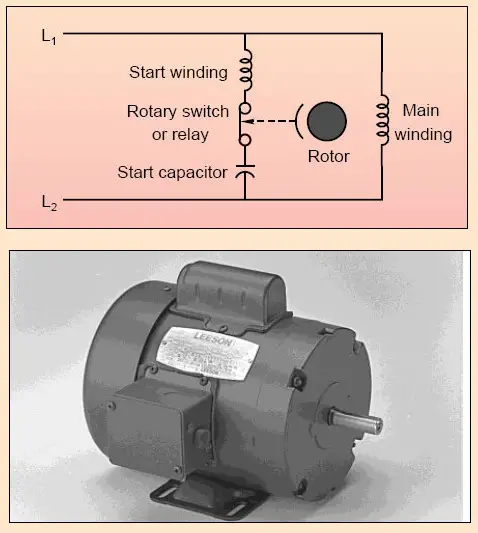

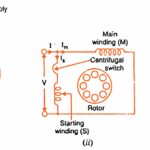

The capacitor start single phase induction motor is a type of split-phase induction motor. Capacitors are used to improve the starting and running performance of the single-phase inductions motors.

The capacitor start motor is identical to a split-phase motor except that the starting winding has as many turns as the main winding.

Working of Capacitor Start Motor

The value of the capacitor is so chosen that the current Is in the auxiliary coil leads current Im in the main coil by about 80° (i.e., α ~ 80°) which is considerably greater than 25° found in split-phase motor. This becomes a balanced 2 phase motor if the magnitude of Is and Im are equal and are displaced in time phase by 90° electrical degrees.

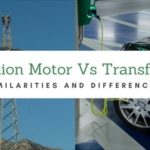

Consequently, starting torque (Ts = kImIssinα) is much more than that of a split-phase motor. The starting winding is opened by the centrifugal switch when the motor attains about 75% of synchronous speed.

The motor then operates as a single-phase induction motor and continues to accelerate until it reaches the normal speed.

The motor will start without any humming noise. However, after the auxiliary winding is disconnected, there will be some humming noise.

Since the auxiliary winding and capacitor are to be used intermittently, these can be designed for minimum cost. However, it is found that the best compromise among the factors of starting torque, starting current and costs results with a phase angle somewhat less than 90° between Im and Is.

Read: Shaded Pole Motor

Characteristics of Capacitor Start 1ϕ Induction Motor

Although starting characteristics of a capacitor-start motor are better than those of a split-phase motor, both machines possess the same running characteristics because the main windings are identical.

The phase angle between the two currents is about 80° compared to about 25° in a split-phase motor. Consequently, for the same starting torque, the current in the starting winding is only about half that in a split-phase motor.

Therefore, the starting winding of a capacitor start motor heats up less quickly and is well suited to applications involving either frequent or prolonged starting periods

Capacitor start motors are used where high starting torque is required and where the starting period may belong e.g., to drive: (a) compressors (b) large fans (c) pumps (d) high inertia loads

The power rating of such motors lies between 120 W and 7-5 kW.

Applications of Capacitor Start Motor

Capacitors in induction run motors enable them to handle heavier start loads by strengthening the magnetic field of the start windings. These loads might include refrigerators, compressors, elevators, and augers.

The size of capacitors used in these types of applications ranges from 1/6 to 10 horsepower. High starting torque designs also require high starting currents and high breakdown torque.