Magnetic hysteresis refers to the phenomenon exhibited by magnetic materials where their magnetization lags behind changes in the applied magnetic field.

Hysteresis means “lagging behind.” With respect to the magnetic flux in an iron core of an electromagnet, the flux lags the increases or decreases in magnetizing force. This phenomenon is called magnetic hysteresis.

Magnetic hysteresis results because the magnetic dipoles are not perfectly elastic. Once aligned by an external magnetizing force, the dipoles do not return exactly to their original positions when the force is removed. The effect is the same as if the dipoles were forced to move against internal friction between molecules.

Furthermore, if the magnetizing force is reversed in direction by reversal of the current in an electromagnet, the flux produced in the opposite direction lags behind the reversed magnetizing force.

Magnetic Hysteresis Loss

When the magnetizing force reverses thousands or millions of times per second, as with rapidly reversing alternating current, hysteresis can cause a considerable loss of energy.

A large part of the magnetizing force is then used to overcome the internal friction of the molecular dipoles. The work done by the magnetizing force against this internal friction produces heat. This energy wasted in heat as the molecular dipoles lag the magnetizing force is called the hysteresis loss.

For steel and other hard magnetic materials, hysteresis losses are much higher than in soft magnetic materials like iron. Hysteresis loss is one of the reason of losses in dc machines and all electrical machines.

When the magnetizing force varies at a slow rate, hysteresis losses can be considered negligible. An example is an electromagnet with direct current that is simply turned on and off or the magnetizing force of an alternating current that reverses 60 times per second or less. The faster the magnetizing force changes, however, the greater the hysteresis effect.

Magnetic Hysteresis Loop

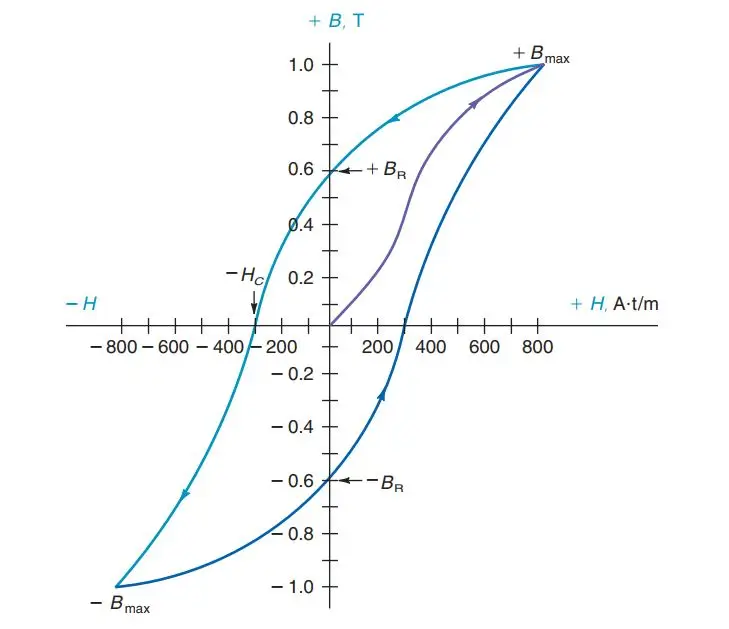

To show the hysteresis characteristics of a magnetic material, its values of flux density B are plotted for a periodically reversing magnetizing force H. This curve is the hysteresis loop of the material.

The larger the area enclosed by the curve, the greater the hysteresis loss. The hysteresis loop is actually a B-H curve with an AC magnetizing force.

Values of flux density B are indicated on the vertical axis. The units can be gauss (G) or teslas (T).

The horizontal axis indicates values of field intensity H. On this axis, the units can be oersteds, ampere-turns per meter, ampere-turns , or magnetizing current because all factors are constant except I.

Opposite directions of current result in opposite directions of +H and -H for the field lines. Similarly, opposite polarities are indicated for flux density as +B or -B.

- The current starts from zero at the center when the material is unmagnetized. Then positive H values increase B to saturation at +Bmax.

- Next, H decreases to zero, but B drops to the value +BR instead of to zero because of hysteresis.

- When H becomes negative, B drops to zero and continues to -Bmax, which is saturation in the opposite direction from +Bmax because of the reversed magnetizing current.

- Then, as the -H values decrease, the flux density is reduced to -BR. Finally, the loop is completed; positive values of H produce saturation at +Bmax again.

- The curve does not return to the zero origin at the center because of hysteresis.

- As the magnetizing force periodically reverses, the values of flux density are repeated to trace out the hysteresis loop.

Retentivity and Coercivity

Retentivity

The value of either +BR or -BR, which is the flux density remaining after the magnetizing force has been reduced to zero, is the residual induction of a magnetic material, also called its retentivity. In the hysteresis loop given, the residual induction is 0.6 T in either the positive or the negative direction.

Coercivity

The value of -Hc, which equals the magnetizing force that must be applied in the reverse direction to reduce the flux density to zero, is the coercive force of the material. In the hysteresis loop above, the coercive force -Hc is 300 AT/m.

Demagnetization

To demagnetize a magnetic material completely, the residual induction BR must be reduced to zero. This cannot be achieved by a reversed DC magnetizing force because the material would become magnetized with opposite polarity.

Practical Approach:

- The practical method involves magnetizing and demagnetizing the material with a continuously decreasing hysteresis loop.

- This process can be achieved using a magnetic field produced by alternating current (AC).

- As the magnetic field and the material are moved away from each other or the current amplitude is reduced, the hysteresis loop becomes smaller and smaller.

- Finally, with the weakest field, the loop collapses practically to zero, resulting in zero residual induction.

- This method of demagnetization is also known as degaussing.

Degaussing

Degaussing is a method of demagnetization used to completely eliminate residual magnetism in a magnetic material. This process involves reducing the residual induction BR of the material to zero. Typically, this cannot be achieved effectively by simply applying a reversed DC magnetizing force, as it would result in the material becoming magnetized with opposite polarity.

Instead, the practical approach to degaussing involves magnetizing and demagnetizing the material with a continuously decreasing hysteresis loop. This is achieved by subjecting the material to a magnetic field produced by alternating current (AC). As the magnetic field and the material are gradually moved away from each other or the current amplitude is reduced, the hysteresis loop becomes smaller and smaller.

Eventually, with the weakest magnetic field, the hysteresis loop collapses practically to zero, resulting in zero residual induction BR. This process effectively demagnetizes the material and is commonly referred to as degaussing.

Comments are closed.