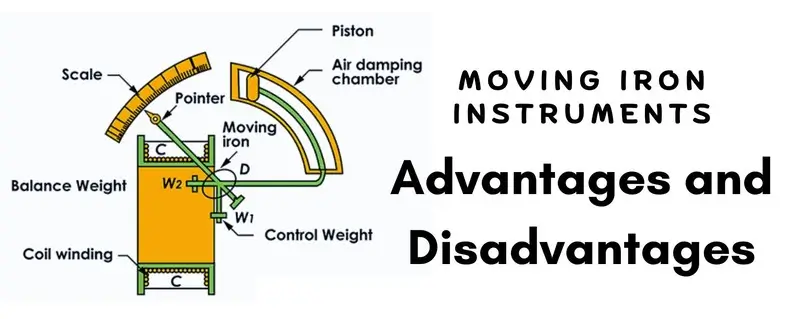

Moving iron instruments are widely used in electrical measurement systems due to their versatility and cost-effectiveness. They are commonly employed for measuring alternating current (AC) and, to a lesser extent, direct current (DC). In this article, we’ll explore the advantages and disadvantages of moving iron instruments, their applications, and key considerations for their use.

What Are Moving Iron Instruments?

Moving iron instruments are electromechanical devices used to measure electrical quantities like voltage and current. They operate on the principle of magnetic attraction or repulsion between fixed and moving iron pieces. These instruments are known for their robustness, simplicity, and ability to work with both AC and DC circuits. To learn more about how these instruments work, you can read this detailed guide on Moving Iron Instruments: Attraction and Repulsion Type.

Advantages of Moving Iron Instruments

Moving iron instruments offer several benefits, making them a popular choice in industrial and laboratory settings. Below are the key advantages:

1. Universal Use

- Application: These instruments can measure both AC and DC quantities.

- Limitation: While they can measure DC, hysteresis effects cause significant errors. As a result, they are rarely used for DC except in low-cost applications like automotive current indicators.

- Primary Use: Moving iron instruments are extensively used for AC measurements in industries where errors of 5% or less are acceptable.

2. Less Friction Errors

- Reason: The torque-to-weight ratio is high because the current-carrying part is stationary, and the moving parts are lightweight.

- Benefit: This reduces friction errors, ensuring more accurate measurements.

3. Cost-Effectiveness

- Design Flexibility: The same moving system can be used across a wide range of instruments, from voltmeters to ammeters.

- Example: A 2mA ammeter may use a single turn, while a voltmeter in the same series may require 40 turns for full-scale deflection.

- Result: This standardization reduces manufacturing costs, making moving iron instruments affordable.

4. Robust Construction

- Durability: The instruments are robust due to their simple design and lack of current-carrying moving parts.

- Application: Ideal for industrial environments where durability is essential.

5. High Accuracy

- Precision: Modern moving iron instruments can achieve an accuracy of 2% or less for DC measurements.

- Industrial Use: High-grade instruments can achieve 0.75% accuracy at frequencies between 25 Hz and 125 Hz, with even better precision (0.2% to 0.3%) at 50 Hz.

6. Extended Scale Length

- Feature: Moving iron instruments are available with scales up to 240 degrees.

- Benefit: The longer scale length improves readability, though the scale is non-uniform and cramped at the lower end.

Disadvantages of Moving Iron Instruments

Despite their advantages, moving iron instruments have some limitations that users should be aware of. For a deeper dive into the errors associated with these instruments, check out this resource on Errors in Moving Iron Instruments.

1. Hysteresis and Frequency Errors

- Issue: Hysteresis effects cause errors in DC measurements.

- Frequency Sensitivity: Accuracy is affected by changes in frequency and stray magnetic fields.

2. Non-Uniform Scale

- Problem: The scale is cramped at the lower end, making it difficult to obtain accurate readings in that range.

3. Waveform Errors

- Cause: The non-linear B-H curve of iron means the deflecting torque isn’t perfectly proportional to the square of the current.

- Impact: This leads to errors when measuring non-sinusoidal waveforms, especially in industrial-grade instruments.

4. Difference Between DC and AC Calibrations

- Reason: The inductance of the meter and eddy currents cause differences between DC and AC calibrations.

- Solution: Instruments must be calibrated for the specific frequencies at which they are used.

Comparison of Moving Iron Instruments for DC and AC Applications

| Aspect | DC Applications | AC Applications |

|---|---|---|

| Accuracy | Lower due to hysteresis effects | Higher, with errors of 5% or less acceptable |

| Frequency Sensitivity | Not applicable | Sensitive to frequency changes |

| Calibration | Requires separate DC calibration | Must be calibrated for specific frequencies |

| Common Use | Rare, except for low-cost indicators | Widely used in industrial settings |

Applications of Moving Iron Instruments

Moving iron instruments are commonly used in:

- Industrial Settings: For measuring AC voltage and current.

- Automotive Systems: As charging and discharging current indicators.

- Laboratories: For general-purpose measurements where high precision isn’t critical.

Key Considerations When Using Moving Iron Instruments

- Calibration: Ensure the instrument is calibrated for the specific frequency and type of current (AC or DC) being measured.

- Waveform: Be aware of potential errors when measuring non-sinusoidal waveforms.

- Scale Limitations: Avoid relying on readings from the cramped lower end of the scale.

- Environmental Factors: Minimize exposure to stray magnetic fields to reduce errors.

Conclusion

Moving iron instruments are versatile, cost-effective, and robust tools for electrical measurements, particularly in AC applications. While they have some limitations, such as hysteresis errors and non-uniform scales, their advantages make them a valuable choice for many industrial and laboratory applications. By understanding their strengths and weaknesses, users can make informed decisions about when and how to use these instruments effectively.