The Vertical Core Type Induction Furnace, also known as the Ajax-Wyatt Furnace, is a specialized type of induction furnace designed for efficient metal melting and refining. This furnace improves upon the limitations of traditional direct-core type induction furnaces, providing better magnetic coupling, higher power factor, and improved operational efficiency. It is widely used in industrial applications, particularly for melting non-ferrous metals like copper and brass.

Why is it Called Ajax-Wyatt Furnace?

The furnace is named after Ajax Magnethermic Corporation and Wyatt, two pioneering companies in the field of induction heating. Ajax Magnethermic specialized in industrial heating equipment, while Wyatt contributed significant advancements in furnace technology. Their collaboration led to the development of this efficient vertical core type induction furnace, which offers superior performance compared to traditional models.

Construction of Vertical Core Type Induction Furnace

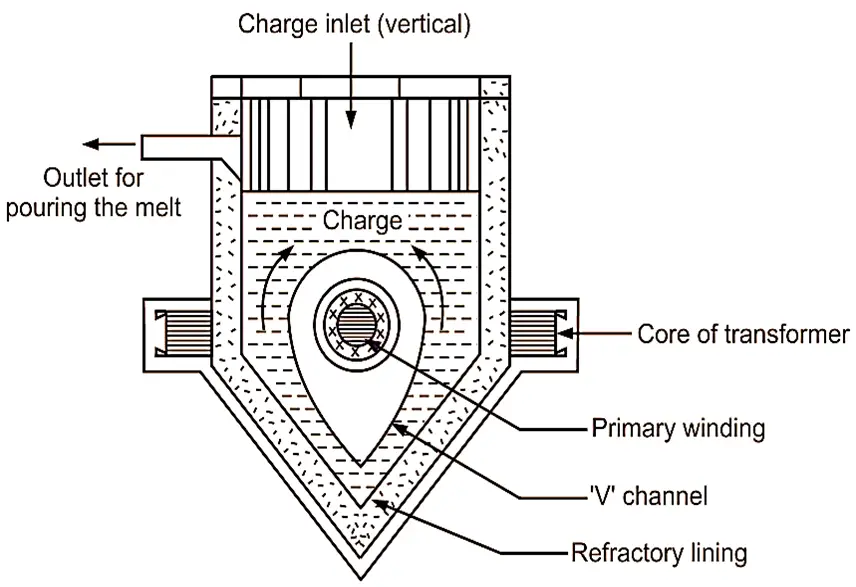

The furnace consists of several key components designed to optimize heat generation and metal processing:

1. Transformer and Core

- The furnace has a horizontal transformer core with a vertical ‘V’-shaped channel where the charge (metal to be melted) is placed.

- The primary winding is connected to an AC power supply, while the secondary winding is formed by the charge itself.

- The ‘V’-shaped configuration improves magnetic coupling between primary and secondary windings, minimizing power losses.

2. Crucible and Charge System

- Unlike direct-core furnaces, the crucible is properly shaped, avoiding operational difficulties.

- An inlet is provided at the top for adding the metal charge.

- A refractory lining is included to reduce heat loss and improve thermal efficiency.

3. Molten Metal Handling

- A pouring outlet is designed for removing molten metal safely and efficiently.

- A mechanical geared fitting at the furnace bottom aids in tilting and metal handling.

Working Principle of Vertical Core Type Induction Furnace

The furnace operates on the principle of electromagnetic induction, generating heat within the charge to melt the metal.

- Maintaining the Molten Metal:

- The ‘V’-shaped channel always contains molten metal, ensuring continuous operation.

- Even when the furnace is idle, a low-voltage AC supply is maintained across the primary coil using an auto-transformer. This keeps the charge in a molten state.

- Melting Process:

- Additional metal is poured into the furnace to be melted.

- When AC supply is applied to the primary winding, it induces a heavy current in the charge housed in the ‘V’ channel.

- This current generates heat due to resistance (Joule heating), melting the charge efficiently.

- Stirring Action and Heat Distribution:

- The circulation of molten metal occurs naturally due to convection currents within the ‘V’-shaped channel.

- Hot metal moves upwards, while cooler metal descends, ensuring uniform heating and composition.

Advantages of Vertical Core Type Induction Furnace

The Ajax-Wyatt Furnace offers several advantages over other types of induction furnaces:

1. Improved Magnetic Coupling

- The ‘V’-shaped channel improves primary-secondary magnetic coupling, reducing power loss and enhancing efficiency.

2. Higher Power Factor

- Compared to direct core furnaces, this furnace has a higher power factor (0.8 to 0.85), reducing power wastage.

3. No Need for Low-Frequency Supply

- Unlike older furnaces that require low-frequency alternators or converters, this furnace operates at standard AC frequencies, reducing overall costs.

4. Avoids Pinch Effect

- The pinch effect (formation of voids and bubbles due to constricting forces in the molten metal) is minimized, improving the quality of the final product.

5. No Odd-Shaped Crucible Required

- The properly shaped crucible makes it easier to handle metal melts, improving metallurgical efficiency.

Applications of Vertical Core Type Induction Furnace

The Ajax-Wyatt Furnace is widely used in industrial applications, particularly for melting non-ferrous metals. Common applications include:

- Copper and brass melting (up to 2 tonnes capacity in commercial settings).

- Foundries for alloy preparation.

- Continuous melting operations in metallurgical industries.

Conclusion

The Vertical Core Type Induction Furnace (Ajax-Wyatt Furnace) is a highly efficient and practical solution for metal melting. It offers better power efficiency, improved heat distribution, and operational reliability compared to traditional induction furnaces. By avoiding the drawbacks of direct-core furnaces, the Ajax-Wyatt Furnace has become a preferred choice in modern industrial melting applications.