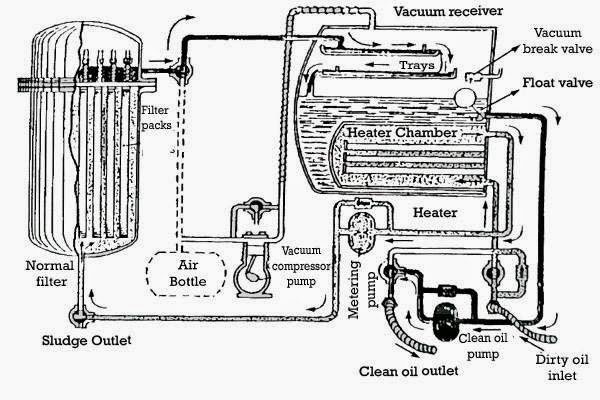

Transformer Oil Filtration Plant is a self-contained unit to upgrade the quantity of oil. The duty cycle begins from pumping the dirty oil from the equipment (or container) to a heat chamber.

After heating the oil to a predetermined temperature, it is then filtered through edge type filter or filter press to remove all suspended impurities. It is then sprayed into a vacuum chamber where the dissolved gases and water are vapourised and separated.

The heaters of the filter plant shall be controlled such that the hot point temperature of oil shall note exceed 90°C as excessive heating will cause deterioration of the oil. Improved designs of Transformer Oil Filtration plants employ heating just to reduce the viscosity and to allow it to spread in a thin film, and high vacuum to remove the dissolved gas and moisture.

Edge type filter elements are made up of special paper discs under end pressure. Oil passes through the infinitesimal interstices between the discs, leaving solid impurities at the paper edges. Non-hygroscopic graded filters can be used in place of edge filters, but they are much costlier.

For reducing acidity, absorption device using activated alumina should be incorporated in the operating cycle of transformer oil filtration.

Read: Transformer Oil Testing

Hot Oil Circulation Process

|

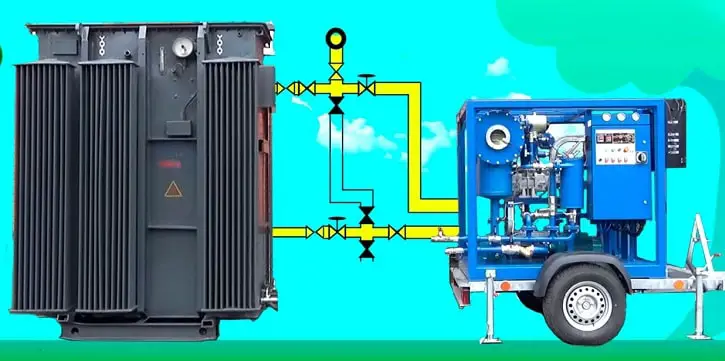

| The Hot Oil Circulation process for Transformer Oil Filtration |

The contaminated oil in a transformer can be treated and the impregnated paper insulation of the transformer can be upgraded by employing closed-circuit continuous circulation of heated dehumidified and filtered oil in the transformer.

The contaminated oil is extracted from the bottom of the transformer, treated in the Transformer Oil Filtration Plant by heating, de-sludging and degassing in a vacuum and the filtered oil is readmitted into the transformer at the top.

Four or five such changes of the complete quantity of oil through the filter plant extracts the moisture from the solid insulation of the transformer and improves the BDV (break down voltage) of the oil.

For filtering power transformers, good quality filter plants are necessary. Single-pass filters, which are capable to upgrade the contaminated oil from BDV 20 kV to 60 kV by one pass, are the desired type. With such plants, transformers can be dried out within a limited time without impairing the quality of the oil.

The desired specification of the Transformer Oil Filtration is as follows:

Type -Single pass to improve BDV from 20 kV to 60kV

Vacuum – 1 Torr

Vacuum pump -1000-1500 liters/minute capacity Ultimate vacuum 0.1 Torr, Rotary type, oil-sealed, direct drive.

Feed pump -Vacuum tight gear pump

Heating system -Designed to avoid localized heating, made of material Nichrome 80/20/Kanthal wire, Temperature controlled thermostatically.

Edge type filter -Specially treated, and with simple cleaning facility.

Discharge pump -High suction, centrifugal

Valves -Vacuum tight, rigorously tested for leak rate.

- Temperature indicators for oil

- Vacuum gauges

- Pressure gauges

- Moisture content meters (if necessary)

- Gas content meters (if necessary)

- Annunciation -Visual and audible alarm for indicating mal-operations.

Oil loss -Less than 2% of the initial volume

Acidity -Mild steel columns, structured Absorption device, Absorbent packing (if required)