DC series motors are used in many applications because of their high starting torque and speed/torque characteristics. Hence speed control of DC series motor are of great importance.

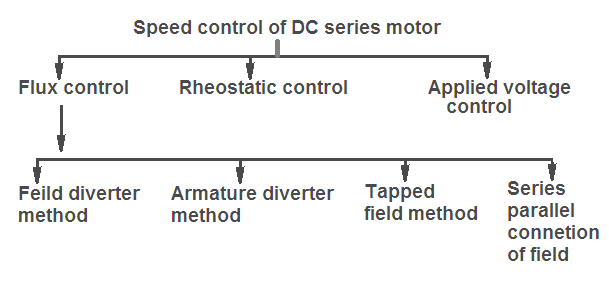

The speed control of DC series motor can be obtained by two methods.

- Flux control method

- Armature-Resistance control method.

The armature-resistance control method is mostly used.

Related: Speed Control of DC shunt Motor

Flux control method

In this method, the flux produced by the series dc motor is varied. The variation of flux can be achieved in the following ways:

- Field Diverters

- Armature Diverter

- Tapped Field Control

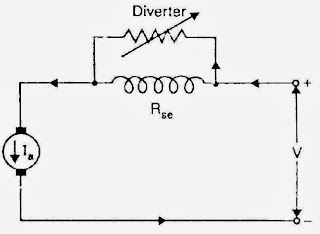

1. Field diverters

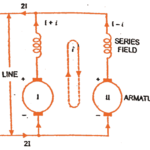

In this method, a variable resistance (called field diverter) is connected in parallel with series field winding.

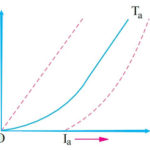

A part of the line current passes through this diverter and thus weakens the field. Since N ∝ 1/ϕ , speed also varies with field flux.

The lowest speed obtained by this method is the normal speed of motor when the current through diverter is zero, ie, diverter open circuited.

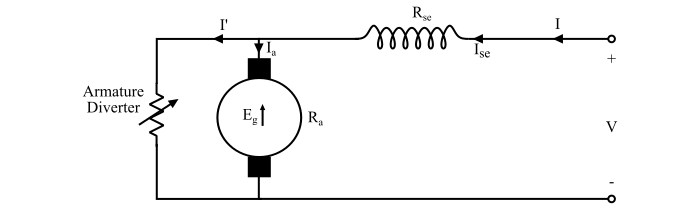

2. Armature diverter

In order to obtain speeds below the normal speed, a variable resistance (called armature diverter) is connected in parallel with the armature of dc series motor.

The diverter reduces the armature current. As a result flux get increased. So the speed decreases since N ∝ 1/ϕ.

For a given load, if armature current (Ia) is decreased, the flux must increase to maintain the load torque (τa ∝ ϕIa) constant. Since the speed (N ∝ 1/ϕ), so the motor speed must decrease. By using armature diverter method, any speed below the normal speed can be obtained.

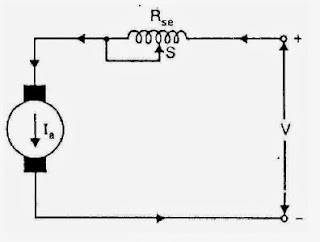

3. Tapped field control

In this method, the flux is reduced (and hence speed is increased) by decreasing the number of turns of the series field winding.

The switch S can short circuit any part of the field winding, thus decreasing the flux and raising the speed.

With full turns of the field winding, the motor runs at normal speed and as the field turns are cut out, speeds higher than normal speed are achieved.

Armature Resistance Control

In this method, a variable resistance is directly connected in series with the supply. This reduces the voltage available across the armature and hence the speed falls.

By changing the value of variable resistance, any speed below the normal speed can be obtained. This is the most common method employed in the speed control of DC series motor.

Here is a table summarizing the methods of speed control of DC series motor.

| Method | Description | Key Points |

|---|---|---|

| Flux Control Method | Varies the flux produced by the series DC motor to control speed. Achieved through field diverters, armature diverters, and tapped field control. | – Field Diverters: Variable resistance in parallel with series field winding. – Armature Diverter: Variable resistance in parallel with the armature. – Tapped Field Control: Reduces flux by decreasing turns of the series field winding. |

| Field Diverters | A variable resistance connected in parallel with series field winding, allowing part of the current to pass through it, weakening the field and varying speed. | – Lowest speed is the normal speed when the diverter is open-circuited. |

| Armature Diverter | A variable resistance connected in parallel with the armature, reducing armature current and increasing flux to decrease speed. | – Used for speeds below the normal speed. |

| Tapped Field Control | Reduces the number of turns of the series field winding to decrease flux and increase speed. | – Motor runs at normal speed with full field winding turns. – Higher speeds achieved by cutting out field turns. |

| Armature Resistance Control | A variable resistance directly connected in series with the supply, reducing voltage across the armature and decreasing speed. | – Allows for any speed below normal speed. – Most common method for controlling speed in DC series motors. |

Comments are closed.